Microbial source combined biostimulant and application thereof

A technology of biostimulants and microbial sources, applied in the field of agricultural applications, can solve the problems of inability to increase production, disease resistance, and stress resistance, and achieve the effects of improving disease resistance and stress resistance, improving disease resistance, and improving crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of polyglutamic acid: polyglutamic acid fermentation broth after fermentation (refer to literature Xu Z, Feng X, DanZ, et, al.Enhanced poly (γ-glutamic acid) fermentation by Bacillus subtilis, NX-2 immobilized in Add concentrated sulfuric acid to aerobic plant fibrous-bed bioreactor[J].Bioresour Technol,2014,155:8-14) to adjust the pH to about 3.5, raise the temperature to 80°C, keep warm and stir for 1 hour, then adjust the pH with sodium hydroxide to 7.5, that is, the polyglutamic acid whose molecular weight is 5-100kDa according to the present invention is prepared;

[0026] Preparation of amino oligosaccharins: crude enzyme preparation prepared by Escherichia coli fermentation was added to 50 g / L chitosan solution at a ratio of 1:100 (v crude enzyme preparation / v substrate volume), and reacted at 50°C for 8 hours. After the reaction mixture is deactivated, it becomes the concentrated solution of amino oligosaccharides, that is, the concentrated solution ...

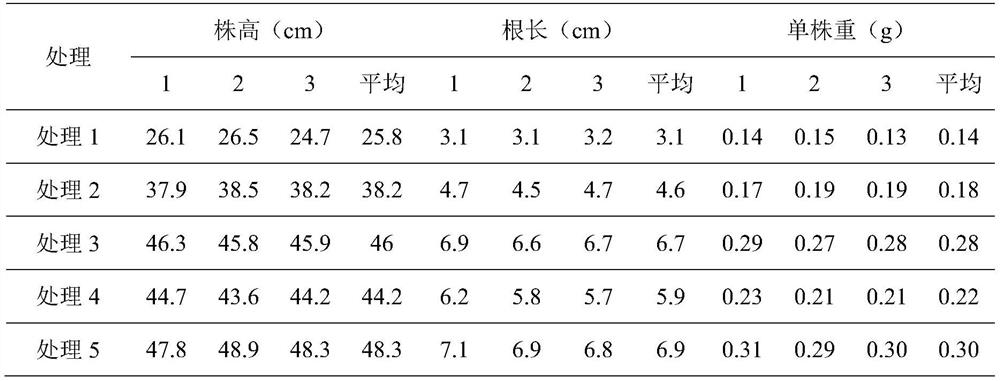

Embodiment 1

[0030] Example 1 A microbial source combined biostimulant and its growth-promoting effect on rice seedlings.

[0031] The combined biostimulants include the following three combinations:

[0032] Combination 1: Mix polyglutamic acid, amino oligosaccharin, microbial polysaccharide, and water to prepare a combined biostimulant. Wherein, the polyglutamic acid concentration is 10g / L, the amino oligosaccharin concentration is 8g / L, and the microbial polysaccharide concentration is 15g / L.

[0033] Combination 2: Mix polyglutamic acid, γ-aminobutyric acid, and water to prepare a combined biostimulant. Wherein, the concentration of polyglutamic acid is 10 g / L, and the concentration of γ-aminobutyric acid is 13 g / L.

[0034] Combination 3: Mix microbial polysaccharides, amino oligosaccharins, γ-aminobutyric acid and water to prepare a combined biostimulant. Wherein, the concentration of microbial polysaccharide is 5g / L, the concentration of oligosaccharin is 8g / L, and the concentrat...

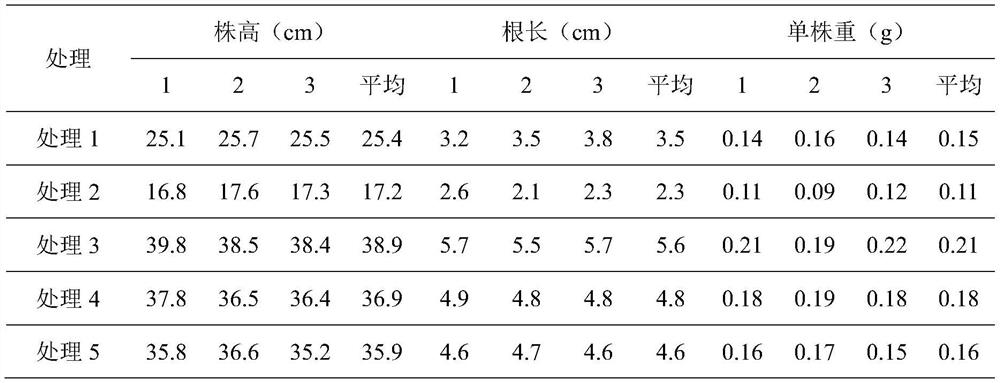

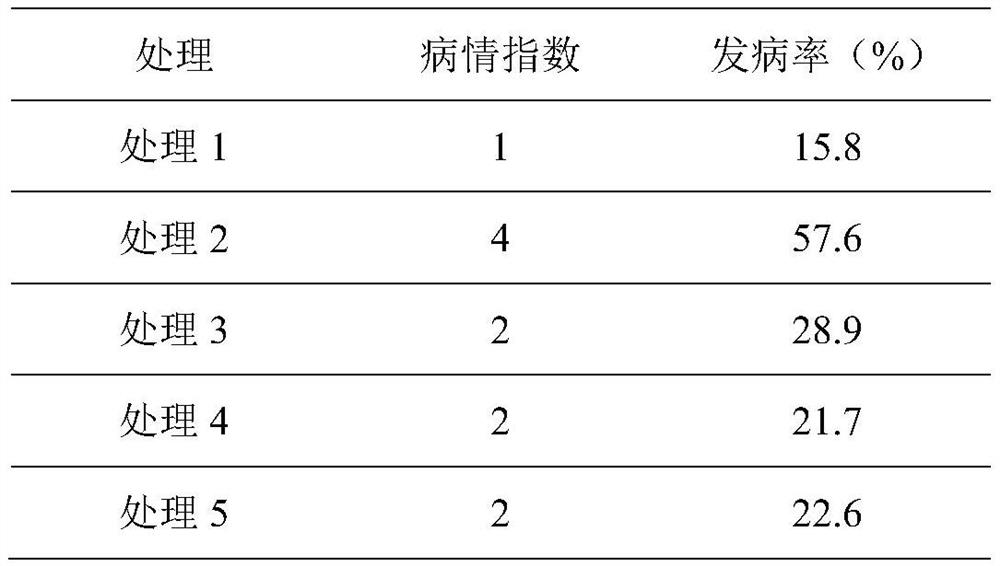

Embodiment 2

[0046] Example 2 Combination biostimulants derived from microorganisms and their effects on rice salt tolerance.

[0047] The combined biostimulants include the following three combinations:

[0048] Combination 4: Mix polyglutamic acid, pantoea and water to prepare a combined biostimulant. Wherein, the polyglutamic acid concentration is 20g / L, and the pantoea polysaccharide concentration is 10g / L.

[0049] Combination 5: Mix pantoea, γ-aminobutyric acid, and water to prepare a combined biostimulant. Wherein, the concentration of pantoea polysaccharide is 10g / L, and the concentration of γ-aminobutyric acid is 13g / L.

[0050] Combination 6: Mix polyglutamic acid, γ-aminobutyric acid, and water to prepare a combined biostimulant. Wherein, the concentration of polyglutamic acid is 10 g / L, and the concentration of γ-aminobutyric acid is 13 g / L.

[0051] In order to investigate the impact of the combined plant biostimulant of the present invention on the salt tolerance of rice,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com