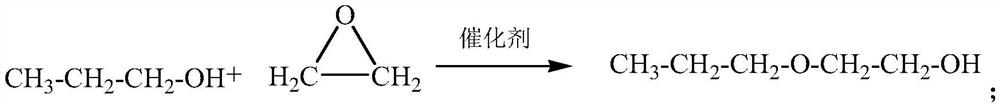

Preparation method and system of ethylene glycol monopropyl ether

A technology of monopropyl ether and preparation system, which is applied in the direction of ether preparation, separation method, and alkylene oxide preparation ether, etc., which can solve the problems of low purity of synthetic crude products, high production cost, and many by-products, so as to avoid the possibility of material contamination , less waste, less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

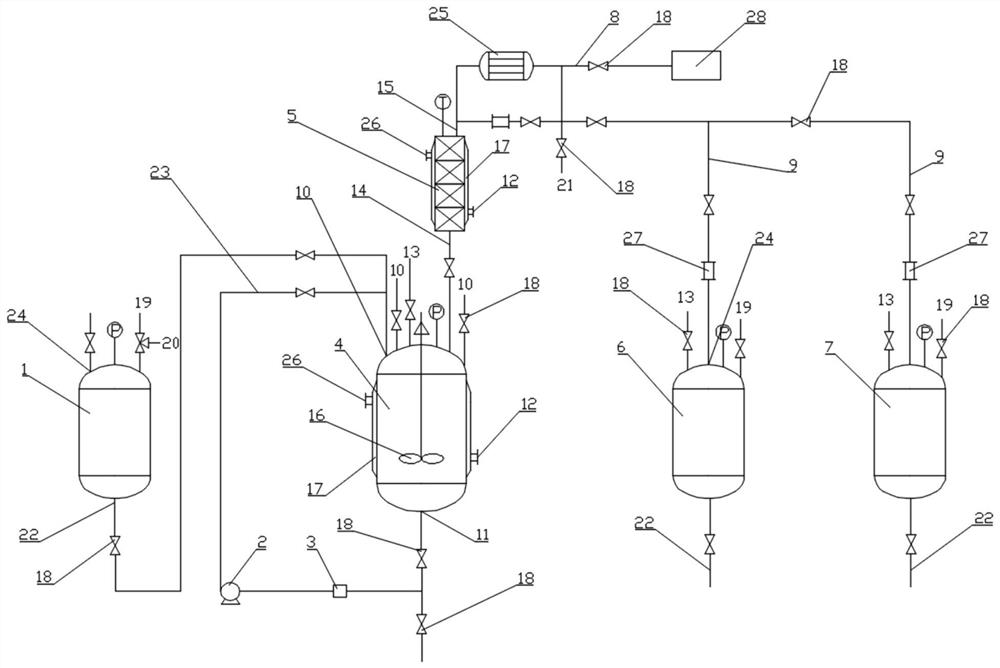

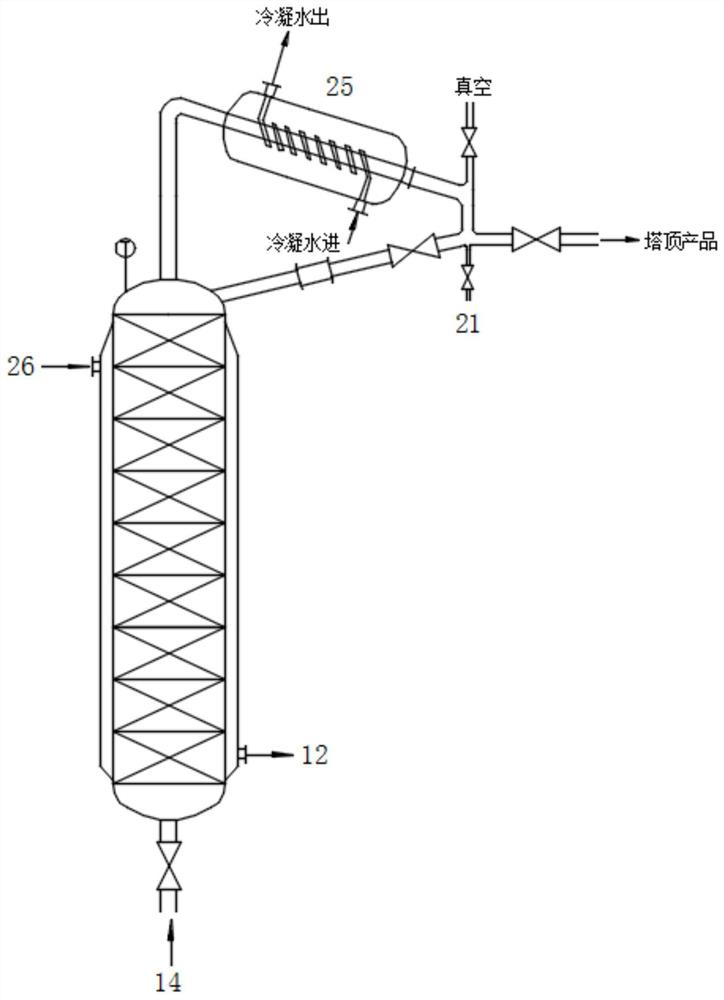

Embodiment 1

[0030] Such as figure 1 and 2 As shown, this embodiment provides a preparation system for ethylene glycol monopropyl ether, including an integrated reaction kettle for addition and rectification. The top is connected with rectifying tower 5. The main body 4 of the reaction kettle is provided with an interlayer 17 for feeding a temperature control medium, such as steam, cooling water (the inlet and outlet of steam and cooling water are just opposite), oil and the like. Reactor main body 4 comprises reaction feed port 10, reaction discharge port 11, protective gas port 13 and material vapor outlet, and reaction feed port 10 and reaction discharge port 11 are respectively arranged on the top and the bottom of reaction kettle main body 4, and reaction feed The feed port 10 and the reaction discharge port 11 are provided with a control valve 18; the reaction discharge port 11 is also connected to the reaction feed port 10 through a return pipe 23, and the return pipe 23 is provid...

Embodiment 2

[0032] Add 60kg of n-propanol and 0.4‰ (accounting for the ratio of n-propanol and ethylene oxide total material, the same below) zinc methanesulfonate catalyst to the addition reaction and rectifying integrated kettle, vacuumize with vacuum pump, adopt N 2Replace the air in the reactor. After three replacements, the degree of evacuation is ≥-0.096MPa. After the material is heated to 100°C, the temperature is raised while adding ethylene oxide. Control the reaction temperature at 165-180° C., and control the total amount of ethylene oxide added to 14 kg. After adding ethylene oxide, keep warm and continue to react until the pressure no longer drops. After the reaction, cool down to 50°C and fill with N 2 To 0.02MPa, take a sample to detect the composition of the crude product, open the control valve of the return pipe, the reaction outlet and the reaction inlet, and filter and recover the catalyst. After the catalyst is recovered, close the control valves of the reaction ou...

Embodiment 2~7

[0046] Table 2 Embodiment 2~7 finished product index

[0047]

[0048] Obtained by table 2 data, the product ethylene glycol monopropyl ether content that rectification method of the present invention makes is more than 99.85%, n-propanol is lower than 0.002%, diethylene glycol monopropyl ether is lower than 0.003% .

[0049] 3. Application of catalyst

[0050] Synthetic reaction process condition is the same as embodiment 3, only changes catalyst type and catalyst mechanical application times (catalyst recovery cover amount is not enough to add new catalyst slightly again), this is example mechanically with zinc methanedisulfonate and p-toluenesulfonic acid zinc, actual It doesn't stop there. The specific indicators of the crude product are shown in Table 3 and Table 4.

[0051] Table 3 Mechanical parameters and crude product index of zinc methanedisulfonate catalyst

[0052]

[0053] Table 4 Application parameters and crude product index of zinc p-toluenesulfonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com