Mild amino acid cleansing cream and preparation method thereof

An amino acid, cleansing cream technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of insufficient mildness, incompatibility, low foam volume, etc., achieve strong cleaning performance, improve high temperature or long-term storage Yellowing, long-lasting foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

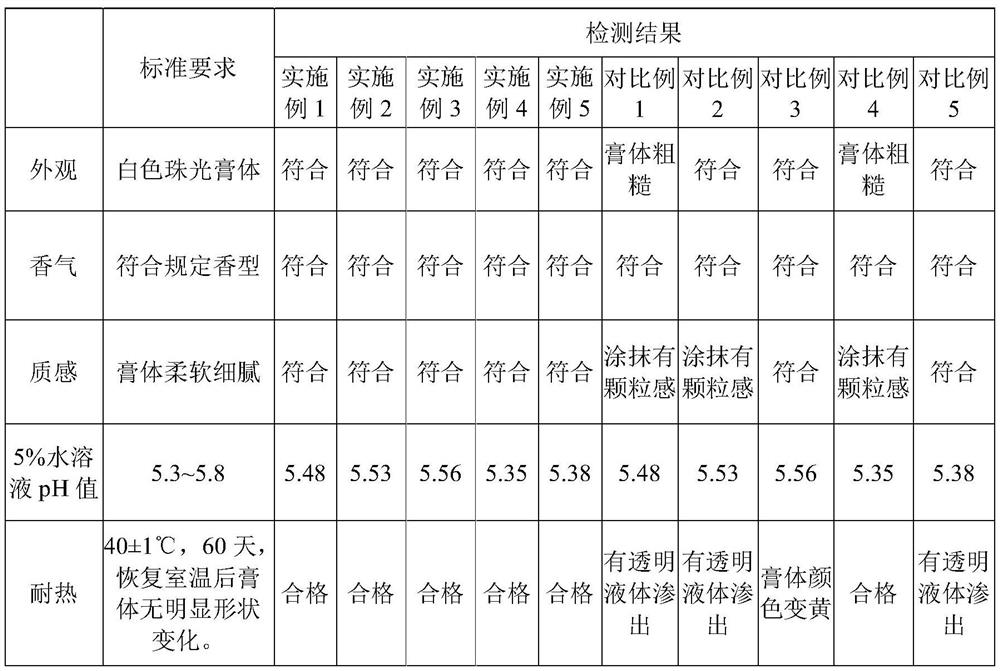

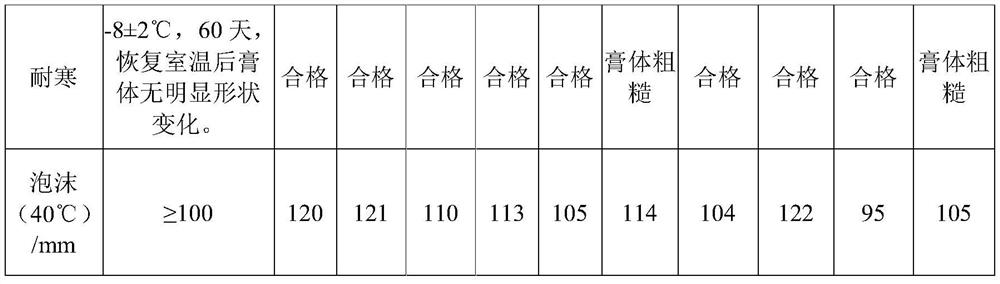

Examples

preparation example Construction

[0052] A preparation method of a mild amino acid cleansing cream, the mild amino acid cleansing cream is the above mild amino acid cleansing cream; the preparation method comprises:

[0053] (1) Mix sodium N-lauroyl glutamate, polyhydric alcohol and water, and heat to 70-85°C to obtain liquid A.

[0054] (2) The above liquid A, sodium methyl cocoyl taurate, sodium glutamate, polyethylene glycol, fatty acid, ethylene glycol distearate, polyglycerol-10 laurate and PEG-120 Methyl glucose dioleate is mixed, heated to 70-85°C, then cooled to 45-55°C, and the rest of the components are added and mixed.

[0055] Preferably, the preparation method further includes: keeping the liquid A at a temperature of 70-85° C. and stirring until the liquid surface is free of bubbles.

[0056] Preferably, in step (2) of the above-mentioned preparation method: after cooling down to 45-55°C, first add the acrylate copolymer thickener, stir homogeneously at a low speed, and then add other remaining ...

Embodiment 1

[0060] A cleansing cream, its raw materials include the following components in parts by weight: 67 parts of deionized water, 15 parts of sodium N-lauroyl glutamate, 10 parts of 1,3-propylene glycol, sodium methyl cocoyl taurate 3 parts, sodium glutamate 2 parts, macrogol-8 1 part, lauric acid 1 part, ethylene glycol distearate 1 part, polyglyceryl-10 laurate 1 part, PEG-120 methyl 0.1 part of dextrose dioleate, 1 part of acrylic acid / steareth-20 methacrylate copolymer, 0.5 part of preservative, 0.1 part of tocopheryl acetate, 0.1 part of disodium EDTA and 0.2 parts of essence.

[0061] The preparation process of this facial cleanser is as follows:

[0062] (1) Add sodium N-lauroyl glutamate and polyhydric alcohol into deionized water, heat to 70°C while stirring to dissolve to obtain liquid A, continue to keep stirring at 70°C until the liquid surface has no bubbles and stop heating;

[0063] (2) Add sodium methyl cocoyl taurate, sodium glutamate, macrogol-8, lauric acid, e...

Embodiment 2

[0065] A cleansing cream, its raw materials include the following components in parts by weight: 40.8 parts of deionized water, 20 parts of sodium N-lauroyl glutamate, 20 parts of 1,3-propylene glycol, sodium methyl cocoyl taurate 5 parts, 3 parts of sodium glutamate, 2 parts of polyethylene glycol-8, 2 parts of lauric acid, 1.5 parts of ethylene glycol distearate, 1.5 parts of polyglyceryl-10 laurate, PEG-120 methyl 0.3 parts of dextrose dioleate, 2 parts of acrylic acid / steareth-20 methacrylate copolymer, 0.5 part of preservative, 0.1 part of tocopheryl acetate, 0.3 part of disodium EDTA and Essence 0.9 parts.

[0066] The preparation process of this facial cleanser is as follows:

[0067] (1) Add sodium N-lauroyl glutamate and polyhydric alcohol into deionized water, heat to 70°C while stirring to dissolve to obtain liquid A, continue to keep stirring at 70°C until the liquid surface has no bubbles and stop heating;

[0068] (2) Add sodium methyl cocoyl taurate, sodium gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com