Method for simultaneously preparing iron phosphate with micro-nano porous structure and 5-hydroxymethylfurfural, and obtained material and application thereof

A hydroxymethyl furfural, porous structure technology, applied in nanotechnology, structural parts, chemical instruments and methods for materials and surface science, can solve problems such as operator and environmental threats, increase production costs, etc., to improve Electrochemical performance, easy operation, simple and fast operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

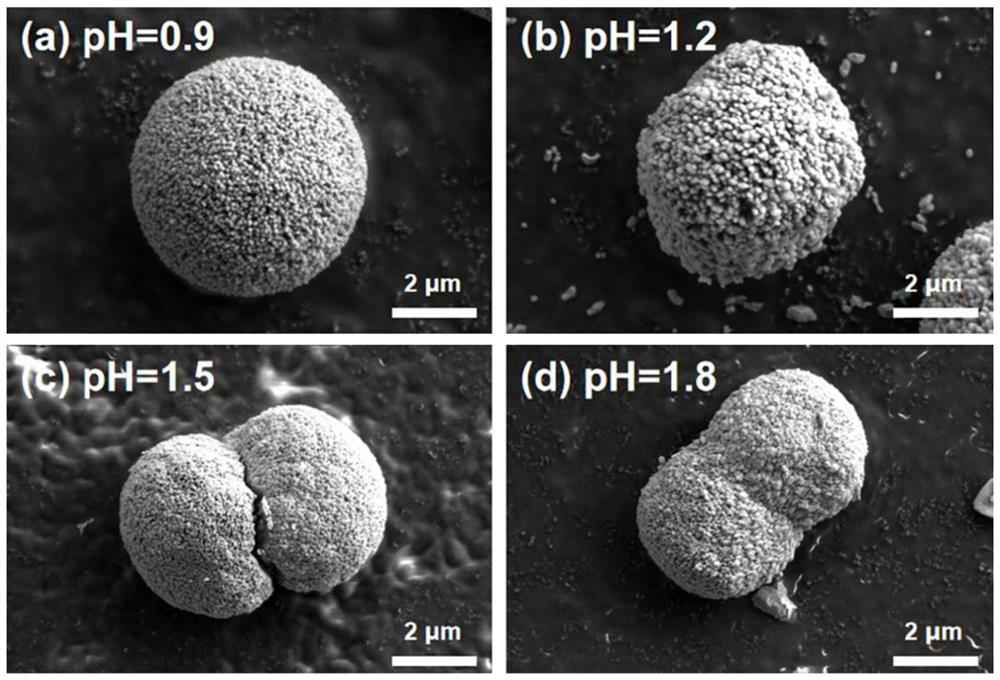

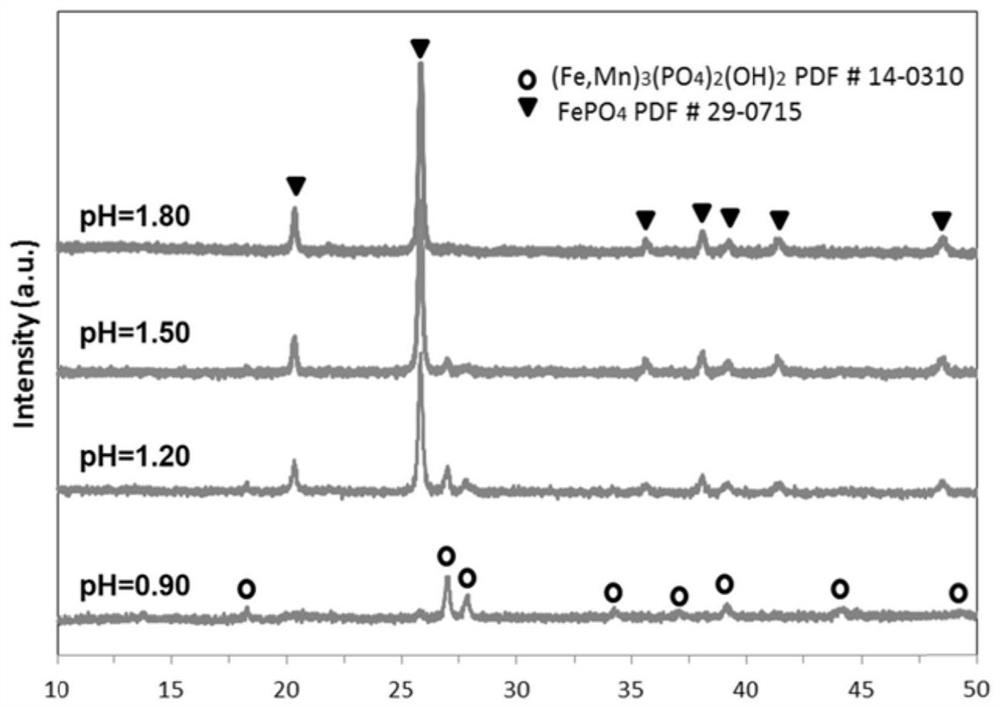

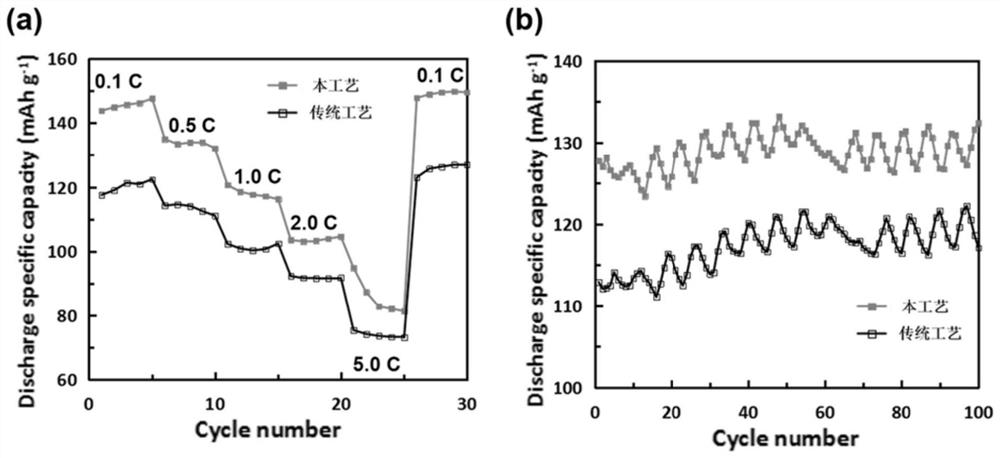

[0023] A simultaneous preparation of FePO with micro-nanoporous structure 4 A fast and green preparation method with 5-HMF, comprising the following steps:

[0024] 1) Preparation of reaction solution: use an analytical balance to accurately weigh ferric nitrate nonahydrate (410.14g, 98.5%) and diammonium hydrogen phosphate (133.39g, 99%), respectively dissolve in a solution containing 20% ethanol, and stir to dissolve , prepared into 1mol / L ferric nitrate solution and 1mol / L diammonium hydrogen phosphate solution. The fructose was accurately weighed with an analytical balance and prepared into a 50% fructose aqueous solution.

[0025] 2) Preparation of FePO4 and 5-HMF with micro-nanoporous structure: Add the prepared ferric nitrate nonahydrate solution and diammonium hydrogen phosphate solution (20ml each) into a 100ml hydrothermal reaction kettle through a peristaltic pump, and the average speed of the peristaltic pump is 57.6 rpm (12.5ml / min). Then add 40 ml of fructos...

Embodiment 2

[0027] A simultaneous preparation of FePO with micro-nanoporous structure 4 A fast and green preparation method with 5-HMF, comprising the following steps:

[0028] 1) Preparation of reaction solution: use an analytical balance to accurately weigh ferric nitrate nonahydrate (410.14g, 98.5%) and diammonium hydrogen phosphate (133.39g, 99%), respectively dissolve in a solution containing 40% ethanol, stir to dissolve , prepared into 1mol / L ferric nitrate solution and 1mol / L diammonium hydrogen phosphate solution. The fructose was accurately weighed with an analytical balance and prepared into a 50% fructose aqueous solution.

[0029] 2) FePO with micro-nano porous structure 4 Preparation with 5-HMF: Add the prepared ferric nitrate nonahydrate solution and diammonium hydrogen phosphate solution (20ml each) into a 100ml hydrothermal reaction kettle through a peristaltic pump, and the average speed of the peristaltic pump is 57.6rpm (12.5ml / min). Then add 40ml of fructose aqueou...

Embodiment 3

[0031] A simultaneous preparation of FePO with micro-nanoporous structure 4 A fast and green preparation method with 5-HMF, comprising the following steps:

[0032] 1) Preparation of reaction solution: use an analytical balance to accurately weigh ferric nitrate nonahydrate (410.14g, 98.5%) and diammonium hydrogen phosphate (133.39g, 99%), respectively dissolve in a solution containing 70% ethanol, stir to dissolve , prepared into 1mol / L ferric nitrate solution and 1mol / L diammonium hydrogen phosphate solution. The fructose was accurately weighed with an analytical balance and prepared into a 50% fructose aqueous solution.

[0033] 2) FePO with micro-nano porous structure 4 Preparation with 5-HMF: Add the prepared ferric nitrate nonahydrate solution and diammonium hydrogen phosphate solution (20ml each) into a 100ml hydrothermal reaction kettle through a peristaltic pump, and the average speed of the peristaltic pump is 57.6rpm (12.5ml / min). Then add 40ml of fructose aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com