Two-dimensional covalent polymer carbon skeleton polymer film and its preparation method and application

A polymer film, carbon skeleton technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of high cost and achieve the effect of reducing the reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] experiment procedure:

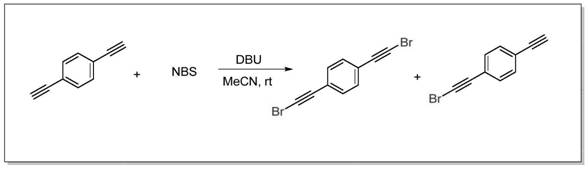

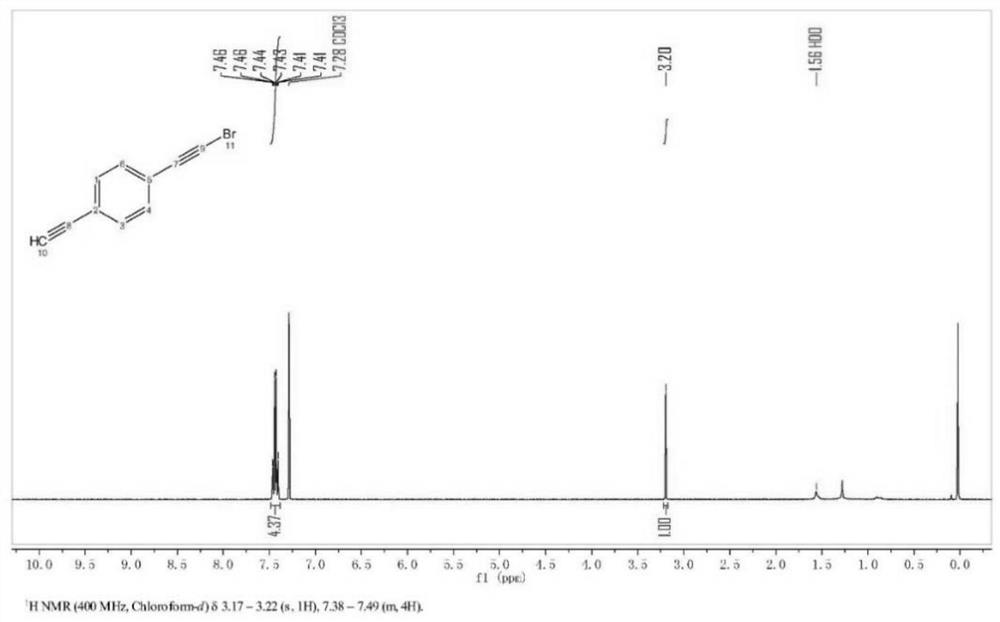

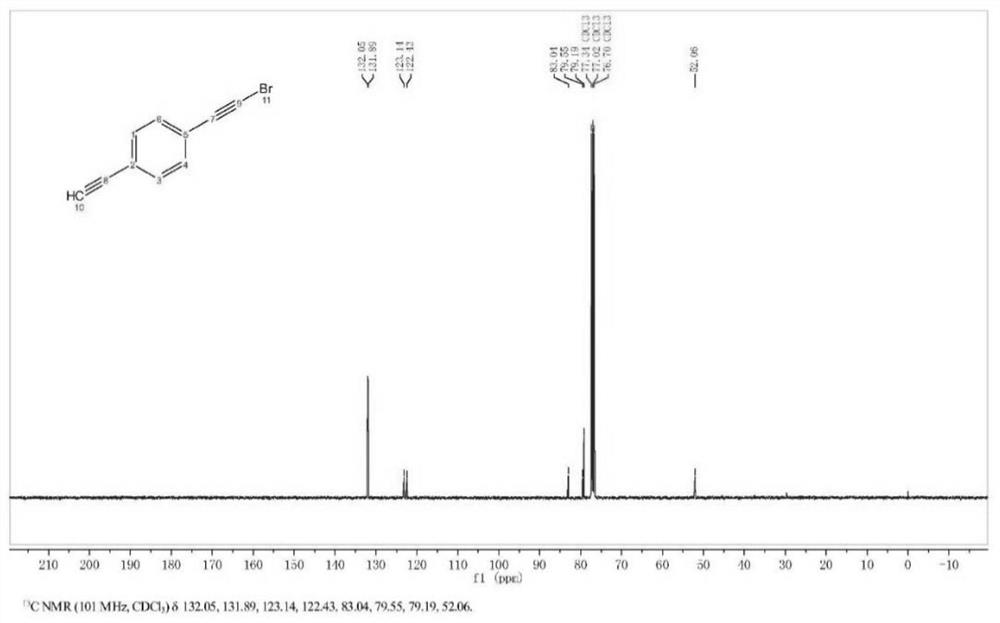

[0062] (1) Weigh one equivalent of a small organic molecule with two alkynyl groups in a conjugated structure, mix 2.0 equivalents of DBU and 2.0 equivalents of NBS in about 10 mL of acetonitrile solution, react at 25°C for 1 hour, and quench with a small amount of water The reaction was quenched, followed by extraction with dichloromethane solvent. The obtained mixed product was purified by column chromatography (the solvent used was n-pentane, 400 mesh silica gel) to obtain the monomer for the subsequent polymerization reaction. ( Figure 9 )

[0063] (2) Wash the metal substrate with a mixed solution of water, ethanol and acetic acid, with a volume ratio of 1:1:1. Blow dry the metal substrate with high-purity nitrogen, and place it in a double-temperature zone tube furnace for high-temperature activation. The gas atmosphere is a mixture of hydrogen and argon, with a hydrogen concentration of 10%. ℃, keep for 60min, then cool down naturally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com