Preparation method of nano-silica modified graphene oxide/epoxy resin composite material

A nano-silicon dioxide and epoxy resin technology, which is applied in the field of epoxy resin composite material preparation, can solve the problems of poor mechanical properties of epoxy resin, decreased strength properties of epoxy resin composite materials, etc., and achieves enhanced interfacial adhesion. , good enhancement effect, inhibition of re-aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

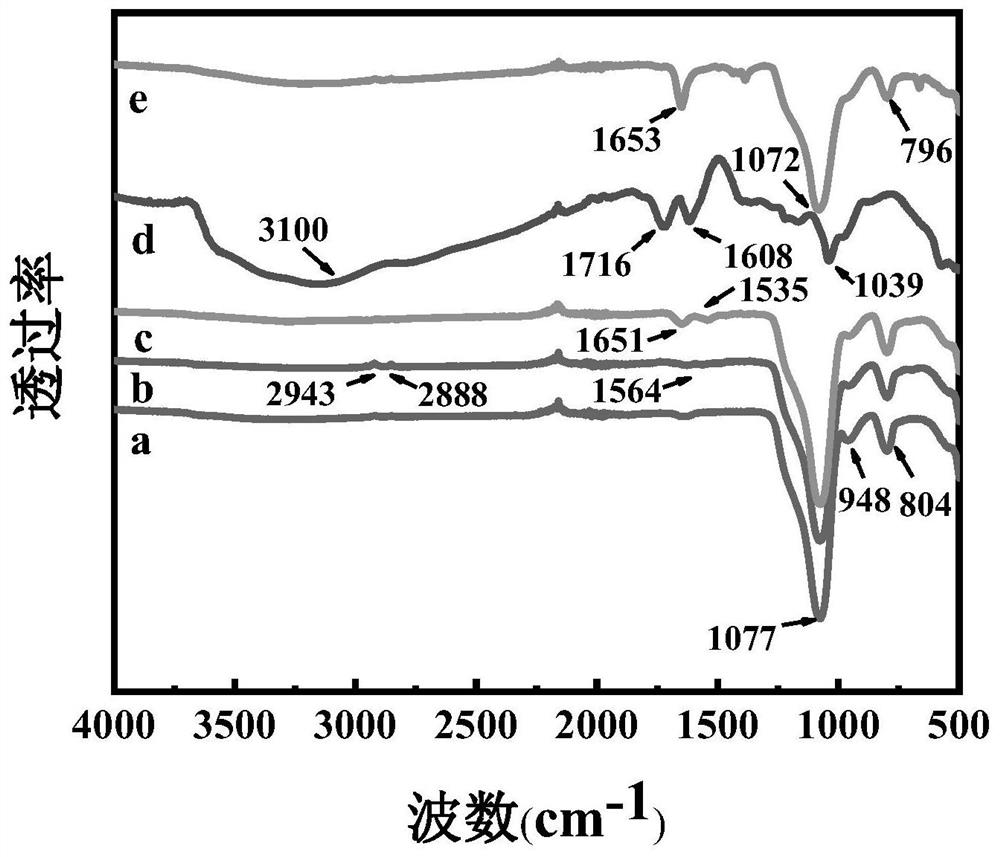

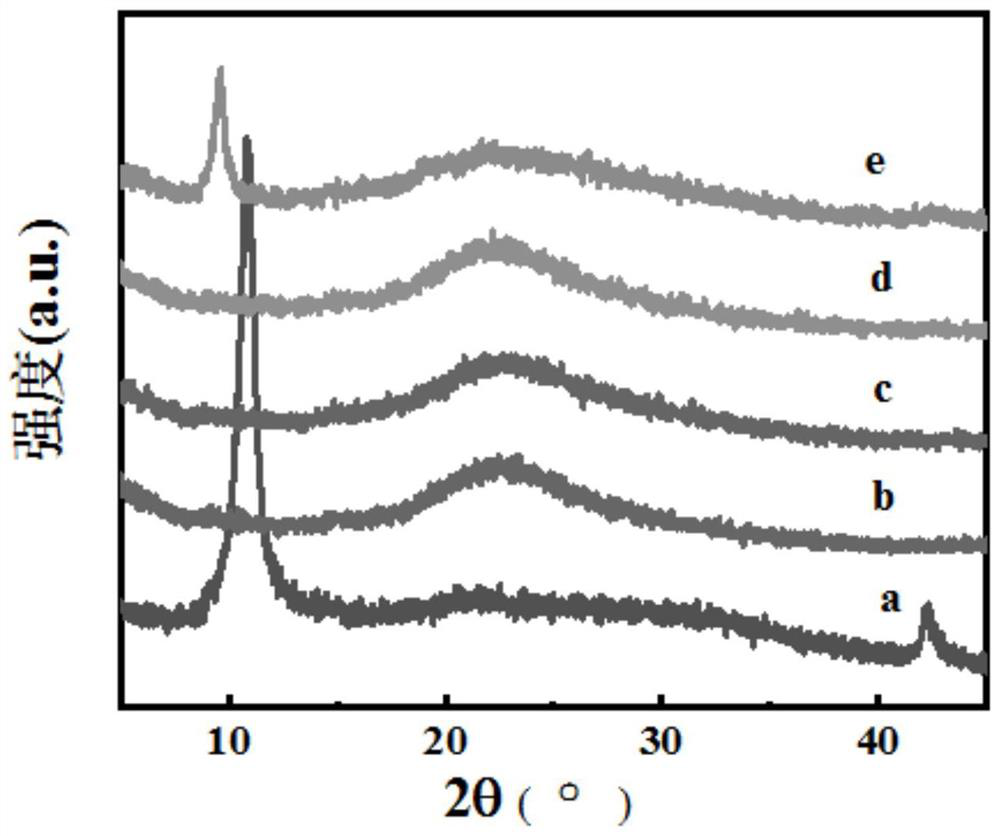

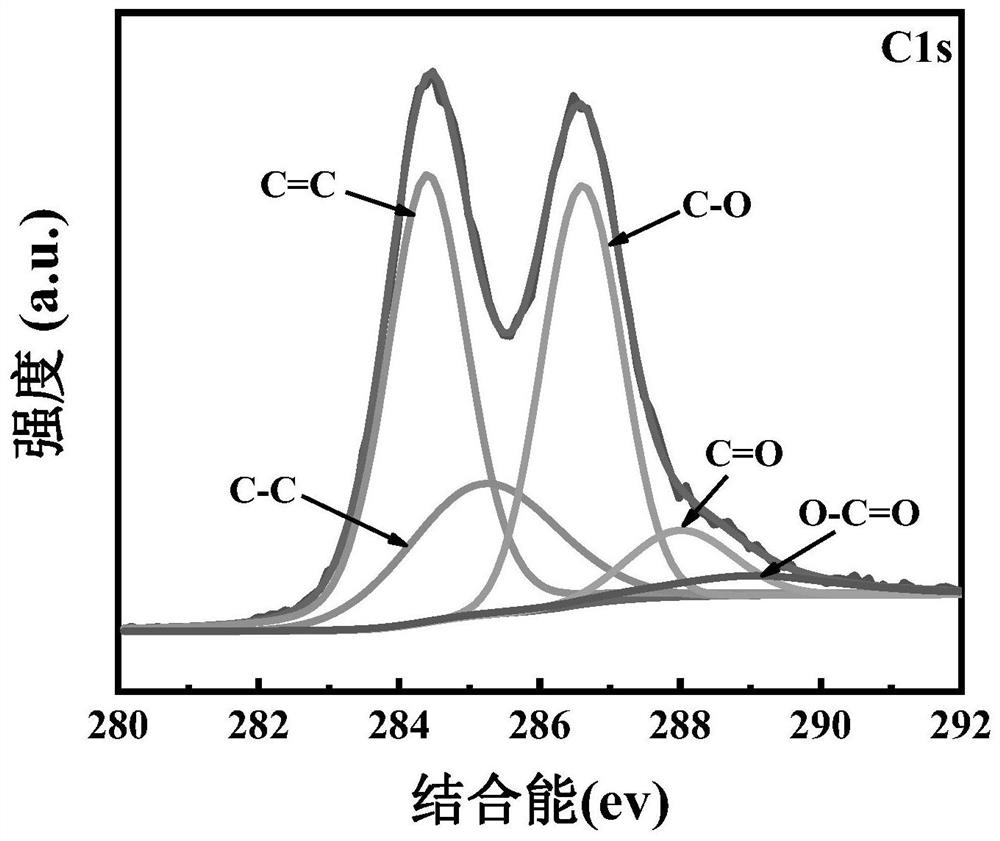

[0039] Specific embodiment one: the preparation method of the graphene oxide / epoxy resin composite material of a kind of nano-silica modification of the present embodiment is completed according to the following steps:

[0040] 1. Silanization of nano-silica:

[0041] ①. Disperse nano-silica in a mixture of absolute ethanol and water, and then ultrasonically obtain a nano-silica dispersion;

[0042] ②. Add a silane coupling agent to the nano-silicon dioxide dispersion, and then stir and reflux at a constant temperature of 70°C to 80°C for 6h to 8h to obtain the reaction solution I;

[0043] ③, first wash the reaction solution I, and then vacuum-dry to obtain silane-functionalized nano-silica;

[0044] 2. Nano silica grafted hyperbranched polymer:

[0045] ①. Disperse the silane-functionalized nano-silica in the mixture of methanol and water, and then ultrasonically obtain the silane-functionalized nano-silica dispersion;

[0046] ②. Add N,N'-methylenebisacrylamide to the si...

specific Embodiment approach 2

[0062] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ultrasonic power described in step one ① is 180W~200W, and the ultrasonic time is 30min~60min; The volume ratio of mass to the mixed solution of absolute ethanol and water is (1g~2g):(100mL~200mL); the volume ratio of absolute ethanol and water in the mixed solution of absolute ethanol and water described in step 1. It is (90~180): (10~20). Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0063] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the silane coupling agent described in step one 2. is 3-aminopropyltriethoxysilane; The mass ratio of the silane coupling agent to the nano-silicon dioxide in the nano-silicon dioxide dispersion liquid is (2-4):(1-2). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com