Hydrate carbon/amorphous molybdenum poly-selenide composite material as well as preparation method and application thereof

A composite material and amorphous technology, applied in chemical instruments and methods, inorganic chemistry, water/sewage treatment, etc., can solve the problems of unsatisfactory palladium adsorption effect, ineffective diffusion, easy agglomeration of molybdenum selenide, etc., and achieve cost Low, excellent removal effect, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

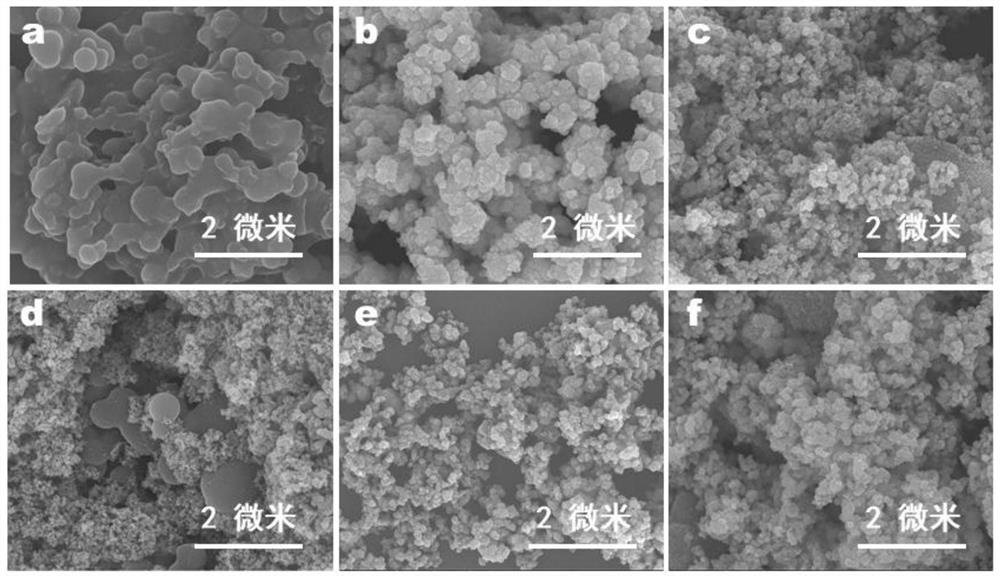

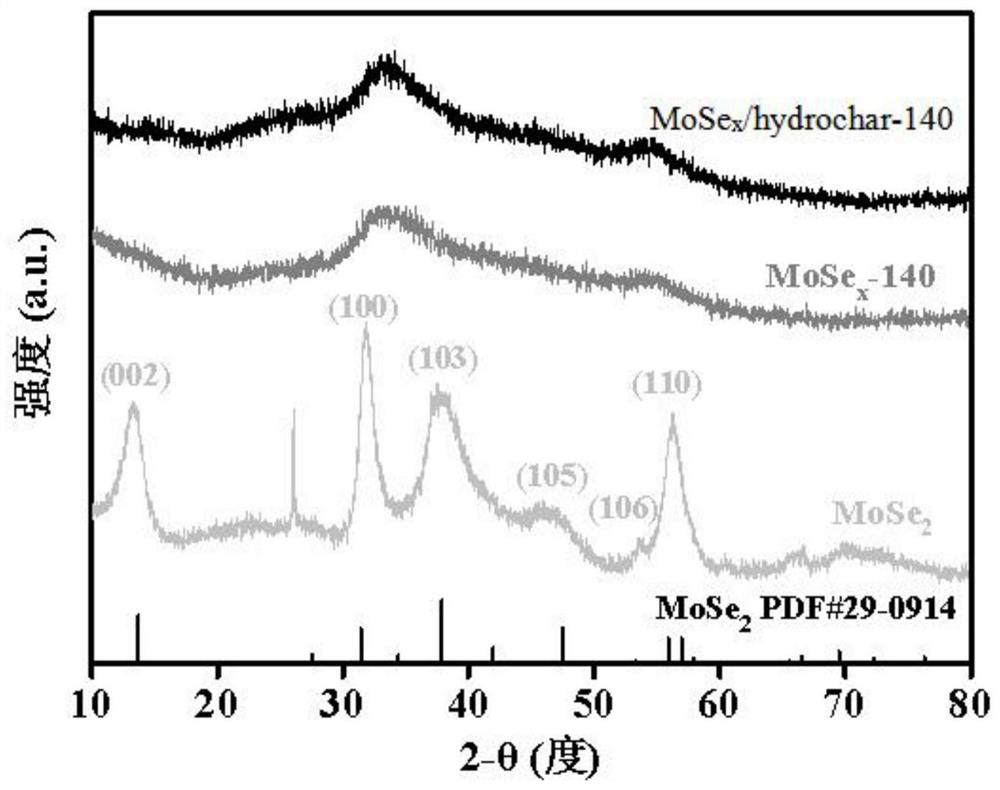

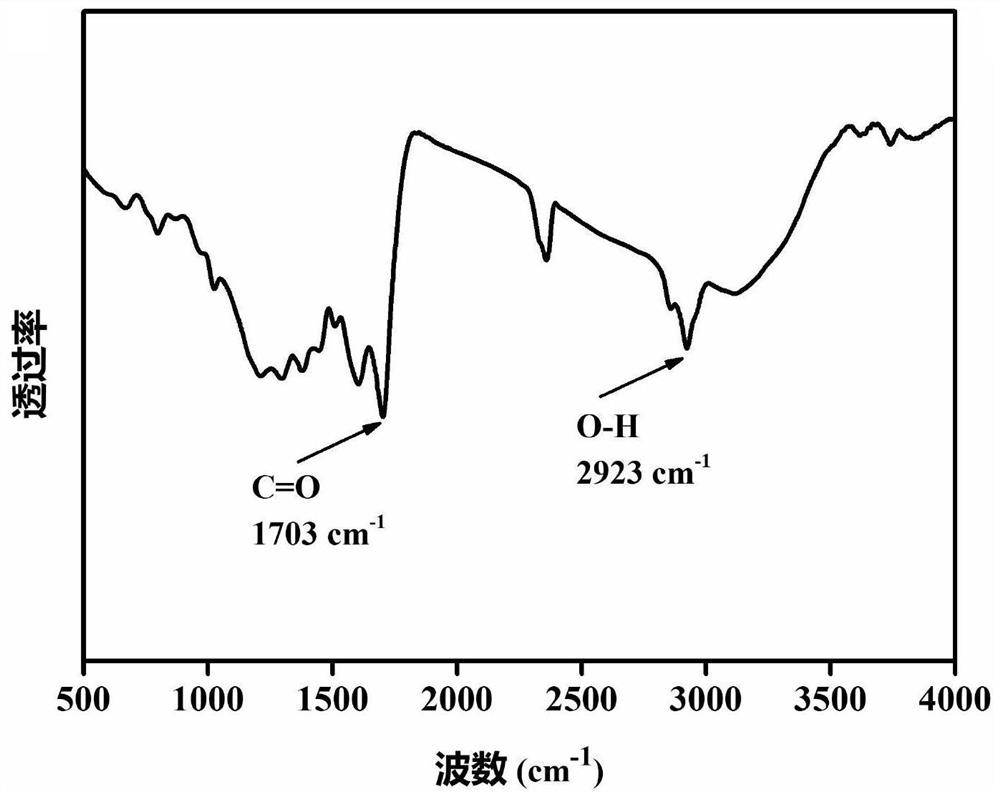

[0039] The present invention provides the preparation method of hydrated carbon / amorphous molybdenum polyselenide composite material described in the above technical scheme, comprising the following steps:

[0040] (1) Mix carbonaceous material and water, carry out hydrothermal carbonization reaction, obtain hydrated carbon;

[0041] (2) Selenium and hydrazine hydrate solution are mixed, carry out redox reaction, obtain selenium anion solution;

[0042] (3) Mix the hydrated carbon, selenium anion solution, ammonium molybdate and organic solvent, and carry out solvothermal reaction to obtain hydrated carbon / amorphous molybdenum polyselenide composite material; the temperature of the solvothermal reaction is not lower than 140 ℃;

[0043] The steps (1) and (2) are not in chronological order.

[0044] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0045] The invention...

Embodiment 1

[0068] Crush 1g of waste cigarette butts to a size of 0.15-0.27mm and mix it with 15mL of water, hydrothermally carbonize at 220°C for 4h, then centrifuge at a speed of 10,000r / min for 10min, wash the obtained solid components with water, and place them at 110°C Dry for 15 hours to obtain hydrated carbon.

[0069] Under room temperature and stirring conditions of 360 r / min, 0.31 g of selenium powder with a particle size of 45-58 μm and 20 mL of hydrazine hydrate solution (80 wt %) were mixed, and then oxidized for 12 hours to obtain a selenium anion solution.

[0070] Add 0.33g of ammonium molybdate tetrahydrate into 20mL of ethanol, add 50mg of carbon hydrate and mix evenly, add the selenium anion solution dropwise and ultrasonically mix for 60min, transfer to the reaction kettle for solvothermal reaction at 140°C for 12h, and cool to After room temperature, centrifuge at a speed of 10000r / min for 10min, wash the obtained solid component with ethanol 3 times, wash with water ...

Embodiment 2

[0072]Prepare hydrated carbon / amorphous molybdenum polyselenide composite material according to the method of embodiment 1, and the difference with embodiment 1 is, the temperature of solvothermal reaction is 160 ℃, obtains hydrated carbon / amorphous molybdenum polyselenide composite material (abbreviation for MoSe x / hydrochar-160).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com