Preparation of carbon nanotube and application of carbon nanotube in lithium ion battery

A technology of carbon nanotubes and metal acetate, which is applied in the direction of carbon nanotubes, nanocarbons, battery electrodes, etc., can solve the problems of cumbersome process steps and equipment and instruments, reduce market competitiveness, and increase battery costs, and achieve a good cycle Performance, cost reduction, and conductivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

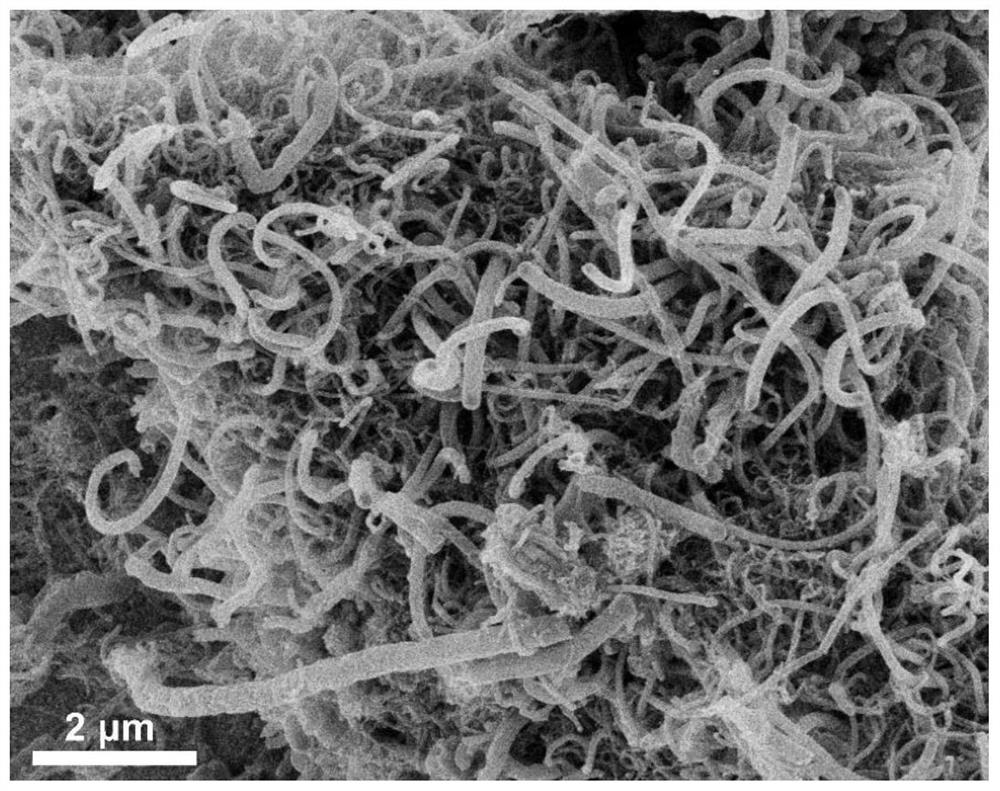

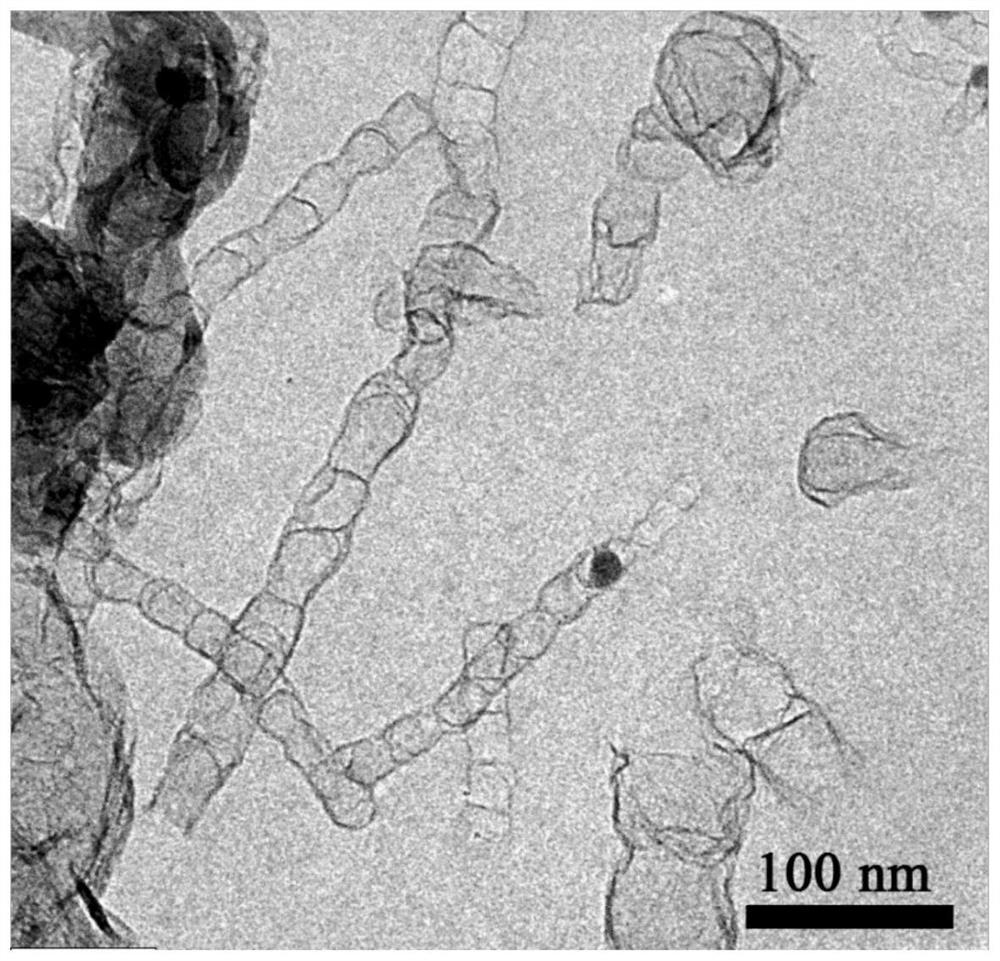

[0036] The invention provides a method for preparing carbon nanotubes, comprising the following steps:

[0037] A) mixing the aqueous solution of metal acetate with nitrogen-containing organic matter, heating and dissolving to obtain a mixed solution;

[0038] Described metal acetate is selected from Ni(CH 3 COO) 2 or Co(CH 3 COO) 2 , the nitrogen-containing organic matter is selected from dicyandiamide, melamine or urea;

[0039] B) heating the mixed solution until the solvent volatilizes to obtain a solid powder of the starting material;

[0040] C) Under a protective atmosphere condition, the solid powder of the starting raw material is calcined by increasing the temperature step by step to obtain carbon nanotubes.

[0041] The present invention first configures the aqueous solution of metal acetate. Specifically, the metal acetate is dissolved in water and subjected to ultrasonic treatment to obtain an aqueous solution of the metal acetate.

[0042] Described metal ...

Embodiment 1

[0065] Weigh 0.2 g Ni(CH 3 COO) 2 Dissolve in deionized water with a volume of 20mL, after ultrasonic treatment for 5 minutes to completely dissolve, weigh 1 gram of dicyandiamide, add the above solution, stir for 10 minutes, heat to 80°C, keep warm for 2 hours, until the solid is completely dissolved , the temperature was raised to 95° C., and the temperature was maintained for 6 hours until all the solvents evaporated, and then the obtained solid powder of the starting material was collected.

[0066] Transfer the solid powder of the above starting raw materials to a corundum magnetic boat, place it in a high-temperature tube furnace, blow in argon to exhaust the air in the tube, raise the temperature to 550 °C at a rate of 10 °C per minute, and calcined for 2 hours. get yellow Ni 2+ -g -C 3 N 4 Sample powder.

[0067] Put the above-mentioned Ni in the corundum crucible in the high temperature tube furnace 2+ -g -C 3 N 4 The powder was continuously heated from 550°C ...

Embodiment 2

[0083] Weigh 0.4 g Ni(CH 3 COO) 2 Dissolve in deionized water with a volume of 30mL, after ultrasonic treatment for 8 minutes to completely dissolve, weigh 2 grams of dicyandiamide, add the above solution, stir for 15 minutes, heat to 75°C, keep warm for 3 hours, until the solid is completely dissolved , the temperature was raised to 97° C., and the temperature was kept for 7 hours until the solvent was completely evaporated, and then the obtained solid powder of the starting material was collected.

[0084]Transfer the solid powder of the above starting raw materials to a corundum magnetic boat, place it in a high-temperature tube furnace, blow in argon to exhaust the air in the tube, raise the temperature to 530 °C at a rate of 12 °C per minute, and calcined for 2.5 hours. get yellow Ni 2+ -g -C 3 N 4 Sample powder.

[0085] Put the above-mentioned Ni in the corundum crucible in the high temperature tube furnace 2+ -g -C 3 N 4 The powder was continuously heated from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com