Halogen-doped basic copper chloride compound as well as preparation method and application thereof

A copper chloride and compound technology, which is applied in the field of halogen-doped basic copper chloride catalyst precursor and its preparation, can solve the problems of many competing products, high selectivity difficulties, complex reaction paths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

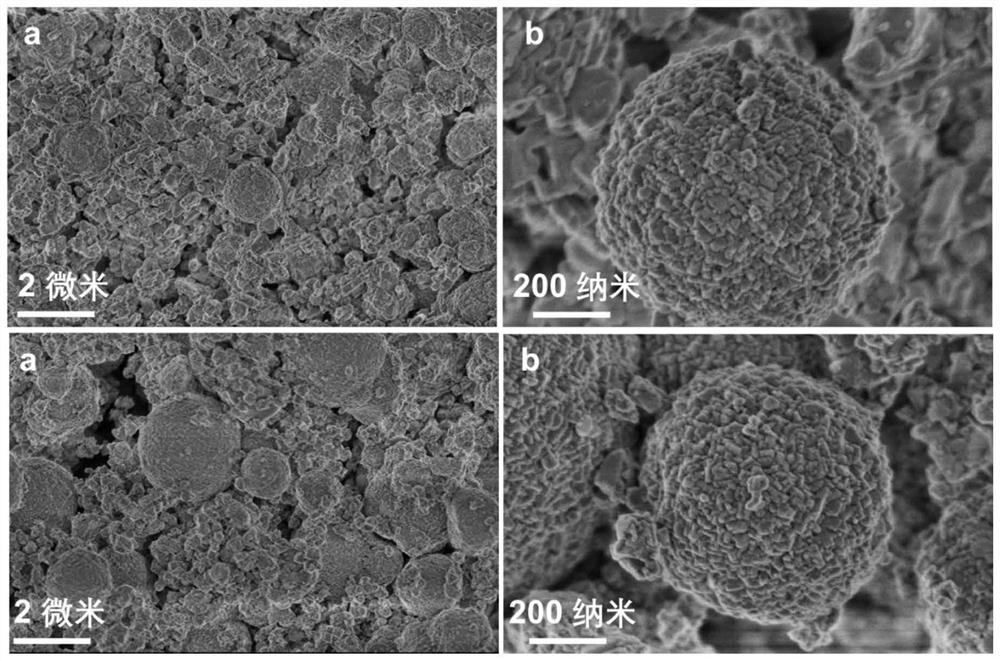

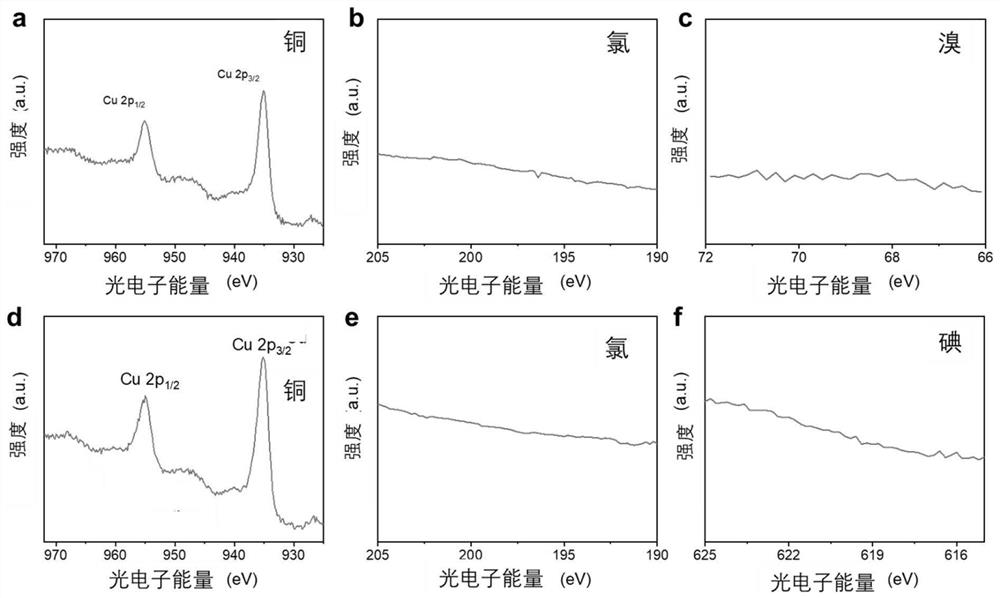

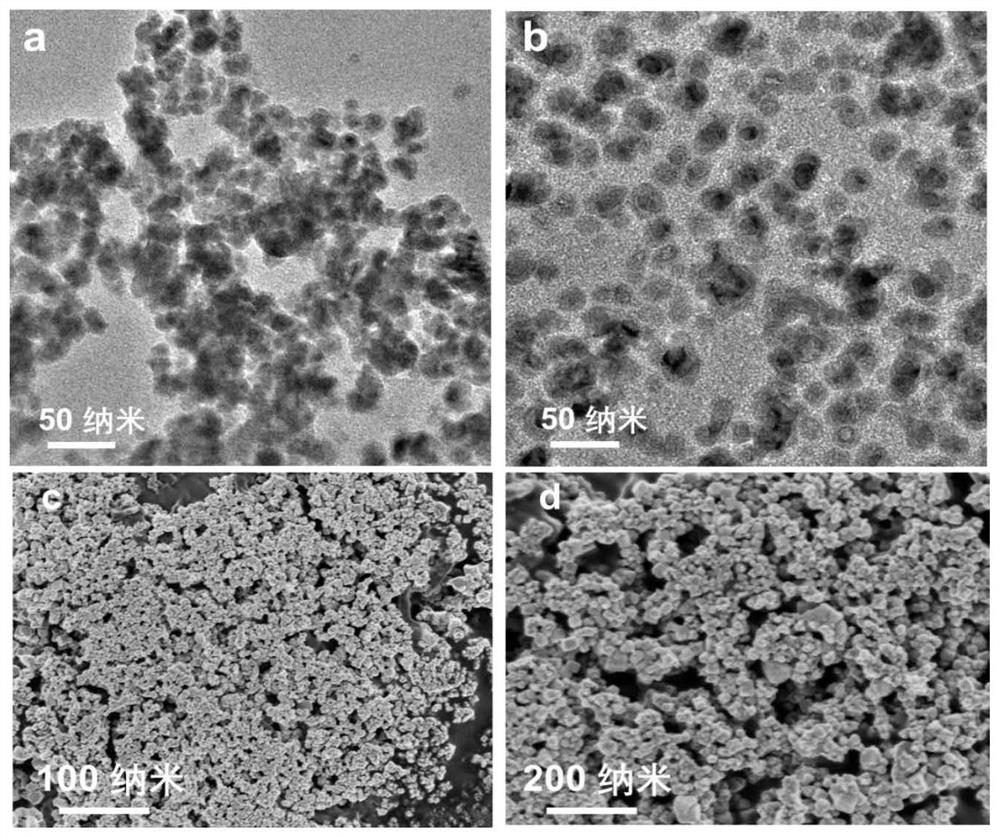

[0022] (1) Preparation of bromine-doped basic copper chloride compound by sol-gel method: Weigh 0.3g of copper dichloride (CuCl 2 ) and 0.03 g of potassium bromide (K bromide), dissolved in a mixed solvent of 4 mL of ethanol and 0.5 mL of deionized water. Then, 1 mL of propylene oxide was added dropwise to the solution and mixed well by shaking. After the solution was allowed to stand for 1 day, 30 mL of acetone was added and allowed to stand for 5 days, and the precipitated product was washed with acetone. After the product is dried, grinding can obtain such as figure 1 a, b, figure 2 a, b, c and image 3 Bromine-doped basic copper chloride shown in a and c.

[0023] (2) Preparation of bromine-doped basic copper chloride compound electrode: Disperse 10 mg of the compound material in a mixed solvent of 1 mL of ethanol and water (volume ratio 1 / 4), and add 80 μL of 5% perfluorosulfur Acid-type polymer solution, after ultrasonication for 30 minutes, the catalyst slurry was...

Embodiment 2

[0025] (1) Preparation of iodine-doped basic copper chloride by sol-gel method: Weigh 0.3g of copper dichloride (CuCl 2 ) and 0.03 g potassium iodide (KI), dissolved in a mixed solvent of 4 mL ethanol and 0.5 mL deionized water. Then, 1 mL of propylene oxide was added dropwise to the solution and mixed well by shaking. After the solution was allowed to stand for 1 day, 30 mL of acetone was added and allowed to stand for 5 days, and the precipitated product was washed with acetone. After the product is dried, grinding can obtain such as figure 1 c, d, figure 2 d, e, f and image 3 Iodine-doped basic copper chloride shown in b and d.

[0026] (2) Preparation of iodine-doped basic copper chloride compound electrode: Disperse 10 mg of the compound material in a mixed solvent of 1 mL of ethanol and water (volume ratio 1 / 4), and add 80 μL of 5% perfluorosulfur Acid-type polymer solution, after ultrasonication for 30 minutes, the catalyst slurry was drop-coated on the glassy ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com