Bio-based high-breathability antibacterial fabric and preparation method thereof

An antibacterial fabric and highly breathable technology, applied in the field of fabrics, can solve the problems of reducing the breathability of fabrics, uncomfortable in use, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

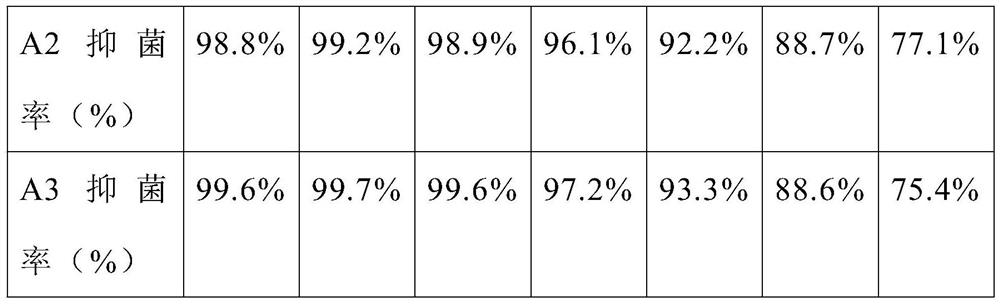

Examples

Embodiment 1

[0051] S1: Prepare raw materials:

[0052] S2: Preparation of modified silica:

[0053] Take hexadecyltrimethylammonium bromide, dissolve it in deionized water, stir for 5 minutes, add ether, ethanol and ammonia water, stir for 30 minutes at 25°C, then add ethyl orthosilicate and mercaptopropyltrimethoxysilane, continue Stir for 4 hours, wash and dry, then place the dried material in a mixed solution of ethanol and hydrochloric acid, reflux at 70°C for 24h, wash, and dry at 60°C to obtain material A;

[0054] Take material A, put it in toluene solution, ultrasonically disperse for 10min, then add mercaptopropyltrimethoxysilane, stir at 80°C for 18h, slowly cool to 25°C, wash, dry, place in hydrogen peroxide, and stir at 28°C React for 48 hours, wash, and dry at 60°C to obtain modified silica;

[0055] S3: Preparation of Additive A:

[0056] Take silver nitrate, glucose and sodium chloride, dissolve in deionized water, stir for 4 hours, then freeze at -15°C for 20 hours, fre...

Embodiment 2

[0066] S1: Prepare raw materials:

[0067] S2: Preparation of modified silica:

[0068] Take hexadecyltrimethylammonium bromide, dissolve it in deionized water, stir for 8 minutes, add ether, ethanol and ammonia water, stir for 35 minutes at 27°C, then add ethyl orthosilicate and mercaptopropyltrimethoxysilane, continue Stir for 4.5 hours, wash and dry, then place the dried material in a mixed solution of ethanol and hydrochloric acid, reflux at 72°C for 24h, wash, and dry at 65°C to obtain material A;

[0069] Take material A, put it in toluene solution, ultrasonically disperse for 12min, then add mercaptopropyltrimethoxysilane, stir at 82°C for 19h, slowly cool to 27°C, wash, dry, place in hydrogen peroxide, and stir at 29°C React for 49 hours, wash, and dry at 65°C to obtain modified silica;

[0070] S3: Preparation of Additive A:

[0071] Take silver nitrate, glucose and sodium chloride, dissolve in deionized water, stir for 5 hours, freeze at -15°C for 22 hours, freeze...

Embodiment 3

[0081] S1: Prepare raw materials:

[0082] S2: Preparation of modified silica:

[0083] Take hexadecyltrimethylammonium bromide, dissolve it in deionized water, stir for 10 minutes, add ether, ethanol and ammonia water, stir for 40 minutes at 28°C, then add ethyl orthosilicate and mercaptopropyltrimethoxysilane, continue Stir for 5 hours, wash and dry, then place the dried material in a mixed solution of ethanol and hydrochloric acid, reflux at 75°C for 24h, wash, and dry at 70°C to obtain material A;

[0084] Take material A, put it in toluene solution, ultrasonically disperse for 15 minutes, then add mercaptopropyltrimethoxysilane, stir at 85°C for 20 hours, slowly cool to 28°C, wash, dry, place in hydrogen peroxide, and stir at 30°C React for 50 hours, wash, and dry at 70°C to obtain modified silica;

[0085] S3: Preparation of Additive A:

[0086] Take silver nitrate, glucose and sodium chloride, dissolve in deionized water, stir for 6 hours, freeze at -15°C for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com