Preparation method and application of rhenium disulfide nano sheet

A technology of rhenium disulfide and nanosheets, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve the problems of preparing nanosheets from rhenium disulfide, achieve excellent catalytic oxidation efficiency, eliminate odor, and excellent crystallization Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

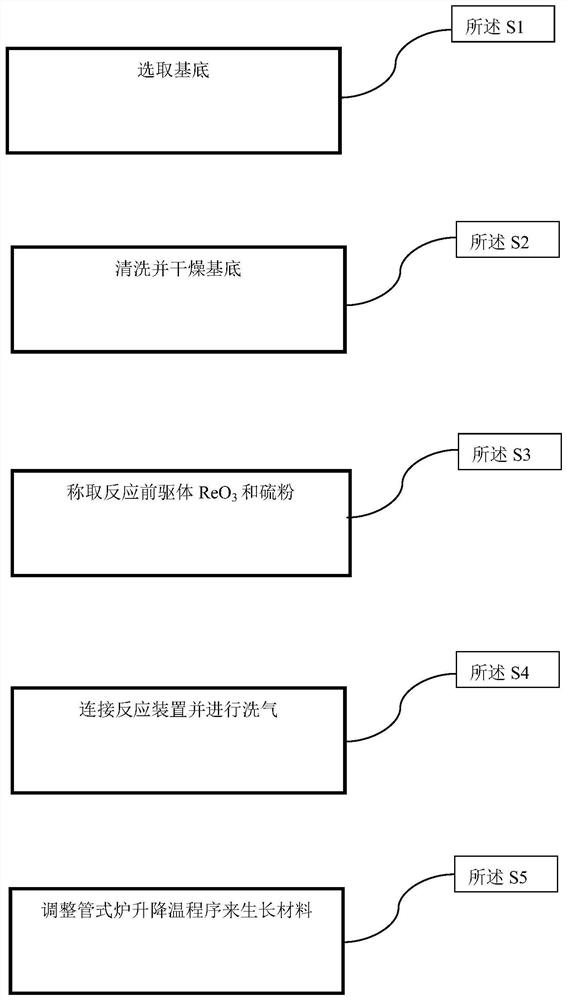

[0051] The invention provides a preparation method of rhenium disulfide nanosheets, comprising the following steps:

[0052] S1. Select a commercially available sailboat brand glass slide and cut it into a size of 2cm*2cm to be used as the growth substrate of the rhenium disulfide bactericidal material. In this embodiment, commercially available glass slides are selected. Currently, commonly used glass slides are easy to obtain and moderate in size and thickness. The nanosheets made by this method have high portability and are convenient for application in different scenarios.

[0053] S2. The cut transparent glass substrate is ultrasonically cleaned for 15 minutes with a sufficient amount of acetone, absolute ethanol, and deionized water in sequence. The ultrasonic power is 100W and the frequency is 40KHz. After cleaning and blowing dry with a nitrogen gun, place it on a heating platform at 70°C for 5 minutes and use it as a growth substrate for later use.

[0054] S3, weigh...

Embodiment 2

[0069] The difference between embodiment 2 and embodiment 1 is:

[0070] S5. The first temperature zone is heated from room temperature (30°C) to 200°C after 47 minutes, and kept for 24 minutes; the second temperature zone is heated from room temperature (30°C) to 260°C after 10 minutes, kept for 30 minutes, and then passed through The temperature is raised to 550°C in 11 minutes and maintained for 20 minutes. The growth temperature of the material is 550°C; the heating program of the third temperature zone is the same as that of the second temperature zone. Cool down to room temperature naturally after growth.

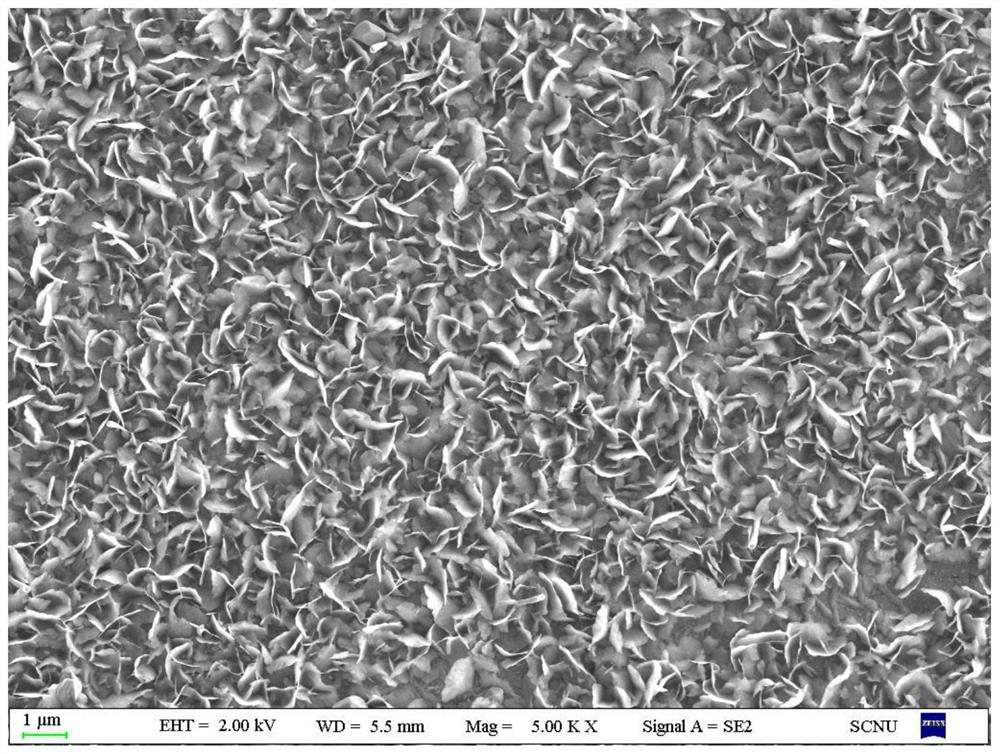

[0071] In the same preparation method, the gasification temperature of the sulfur source is set at 200°C, and the cracking temperature of the rhenium source is set at 550°C, and rhenium disulfide nanosheets with a vertical morphology can also be obtained, which have a uniform and dense distribution and a large specific surface area. characteristics, and exposed a lar...

Embodiment 3

[0073] The difference between embodiment 3 and embodiment 1 is:

[0074] S5. The first temperature zone is heated from room temperature (30°C) to 200°C after 47 minutes, and kept for 24 minutes; the second temperature zone is heated from room temperature (30°C) to 260°C after 10 minutes, kept for 30 minutes, and then passed through The temperature is raised to 600°C in 11 minutes and maintained for 20 minutes. The growth temperature of the material is 600°C; the heating program of the third temperature zone is the same as that of the second temperature zone. Cool down to room temperature naturally after growth.

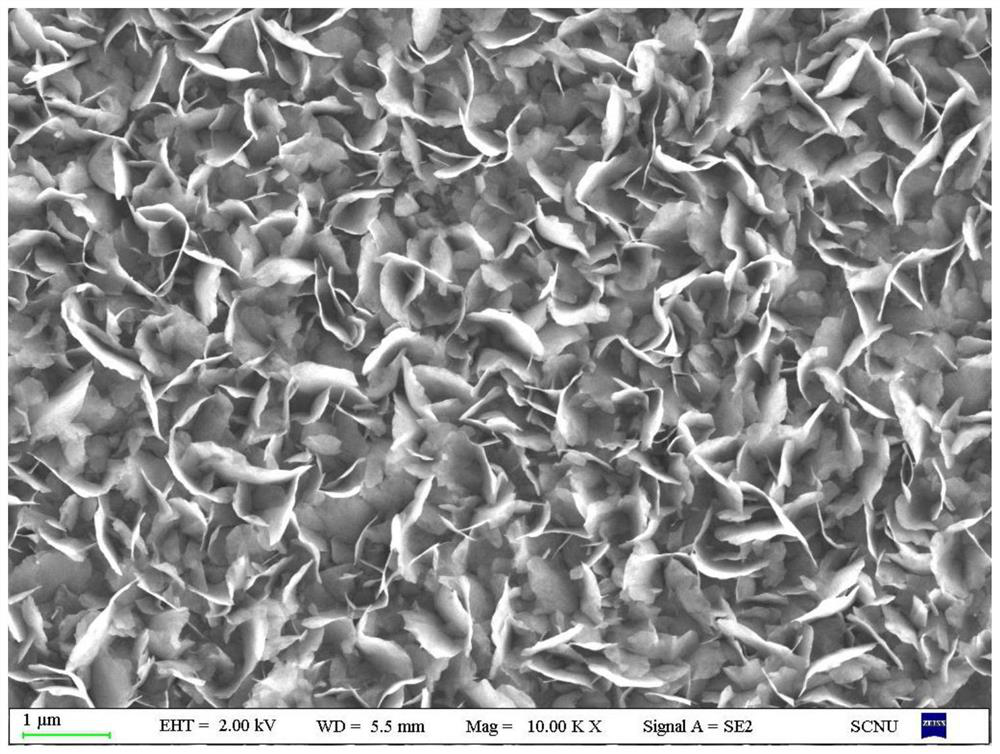

[0075] In the same preparation method, the gasification temperature of the sulfur source is set at 200°C, and the cracking temperature of the rhenium source is set at 600°C, and rhenium disulfide nanosheets with a vertical morphology can also be obtained, which have a uniform and dense distribution and a large specific surface area. characteristics, and exposed a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com