Compound halogen-free flame-retardant plant fiber reinforced polylactic acid material and preparation method thereof

A polylactic acid material and plant fiber technology, which is applied in the field of compound halogen-free flame retardant plant fiber reinforced polylactic acid material and its preparation, can solve the problem of large filling amount, adverse effects on physical properties of materials, deterioration of interface bonding of composite materials, etc. problems, to achieve the effect of small impact on physical properties, improved interface bonding force, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Discuss the influence of different dosages of compound flame retardants on the mechanical properties and flame retardant properties of the prepared polylactic acid / plant fiber composites

[0026] (1) Sample preparation

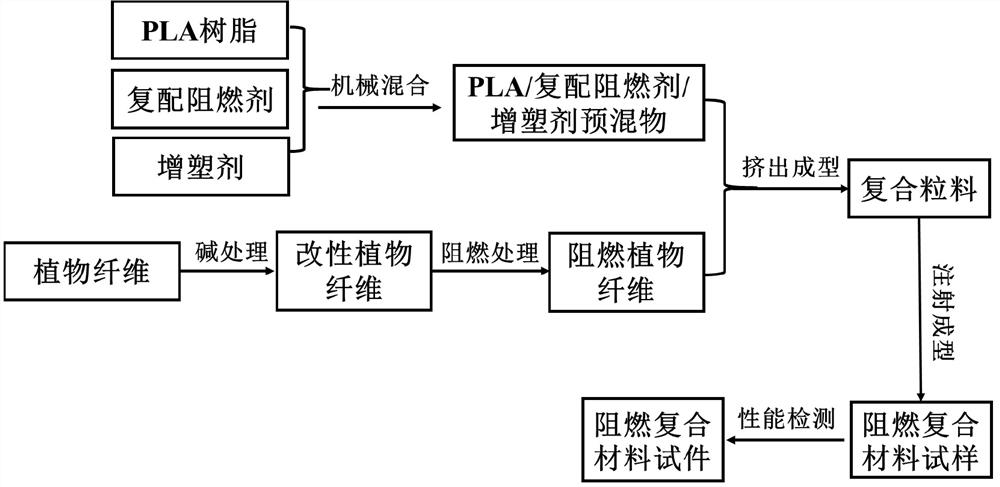

[0027] The composite halogen-free flame-retardant plant fiber reinforced polylactic acid material is prepared by the following method, and the specific steps are:

[0028] (1) Soak the plant fiber in a sodium hydroxide solution with a concentration of 3wt% for 6 hours. After washing with water, soak the plant fiber in water, add acetic acid to it until neutral, take out the plant fiber and dry it to obtain the surface modified Permanent plant fibers, wherein the plant fibers are ramie fibers, the plant fibers are continuous long fibers or chopped fibers, and the diameter of the plant fibers is 20-50 μm.

[0029] (2) Soak the surface-modified plant fiber prepared in step (1) in 3wt% ammonium polyphosphate solution for 7 hours for flame-retarda...

Embodiment 2

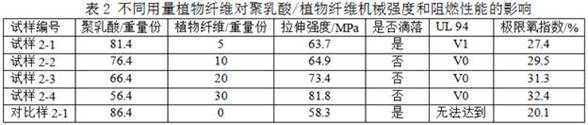

[0048] Example 2 Discuss the influence of different dosages of plant fibers on the mechanical properties and flame retardant properties of the prepared polylactic acid / plant fiber composites

[0049] (1) Sample preparation

[0050] The composite halogen-free flame-retardant plant fiber reinforced polylactic acid material is prepared by the following method, and the specific steps are:

[0051] (1) Soak the plant fiber in a sodium hydroxide solution with a concentration of 3wt% for 6 hours. After washing with water, soak the plant fiber in water, add acetic acid to it until neutral, take out the plant fiber and dry it to obtain the surface modified Permanent plant fibers, wherein the plant fibers are ramie fibers, the plant fibers are continuous long fibers or chopped fibers, and the diameter of the plant fibers is 20-50 μm.

[0052] (2) Soak the surface-modified plant fiber prepared in step (1) in 3wt% ammonium polyphosphate solution for 7 hours, perform flame-retardant pretr...

Embodiment 3

[0062] Example 3 Discuss the effects of different processes on the mechanical properties and flame retardant properties of polylactic acid / plant fibers

[0063] (1) Sample preparation

[0064] The composite halogen-free flame-retardant plant fiber reinforced polylactic acid material is prepared by the following method, and the specific steps are:

[0065] (1) Soak the plant fiber in a sodium hydroxide solution with a concentration of 3wt% for 6 hours. After washing with water, soak the plant fiber in water, add acetic acid to it until neutral, take out the plant fiber and dry it to obtain the surface modified Permanent plant fibers, wherein the plant fibers are ramie fibers, the plant fibers are continuous long fibers or chopped fibers, and the diameter of the plant fibers is 20-50 μm.

[0066] (2) Soak the surface-modified plant fiber prepared in step (1) in 3wt% ammonium polyphosphate solution for 7 hours, perform flame-retardant pretreatment, take it out and dry it, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com