Resonant acceleration sensor based on nano piezoelectric beam and its preparation method

An acceleration sensor, resonant technology, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, instruments, etc., can solve the problems of poor anti-overload ability, low resonant frequency, low sensitivity, etc., and achieve strong anti-overload ability and resonant frequency High, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

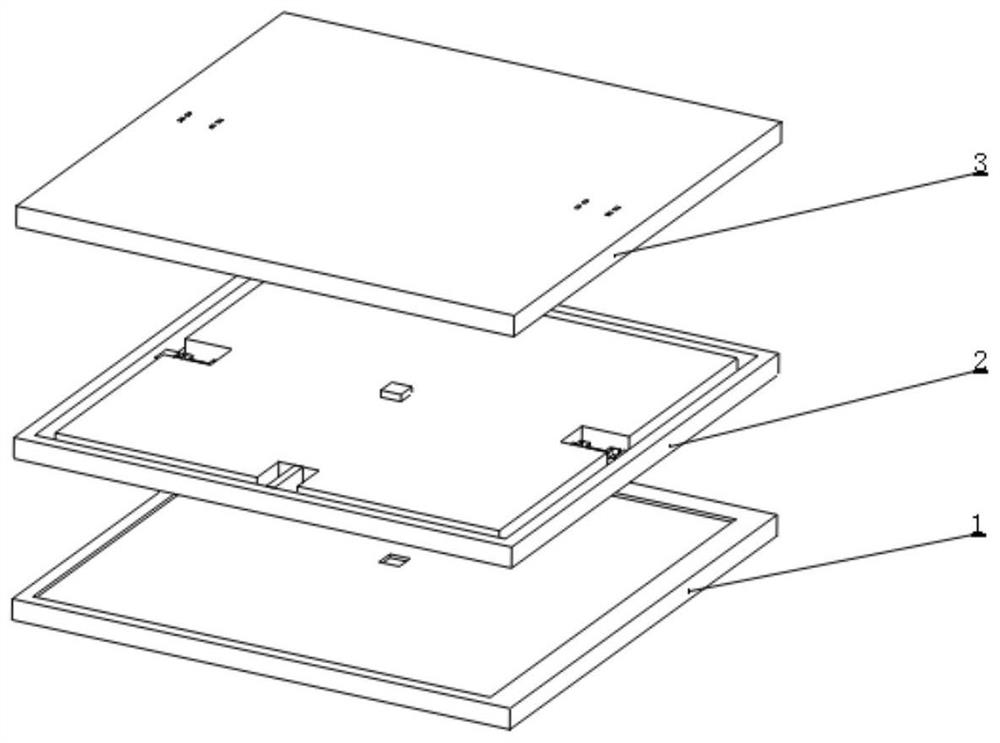

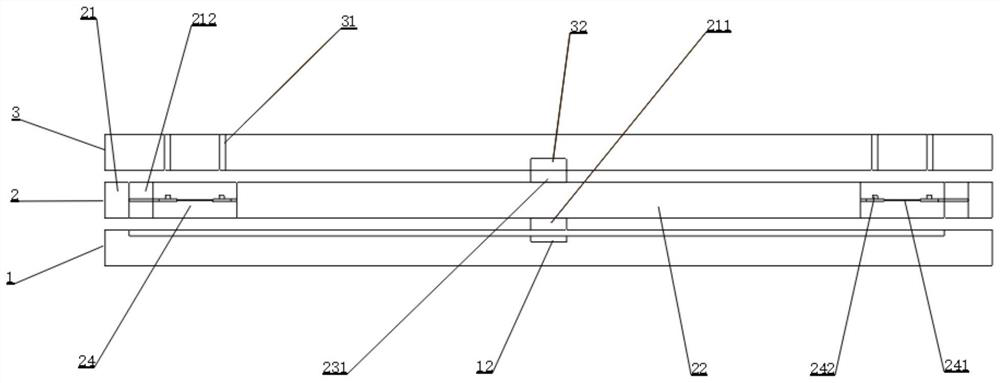

[0054] Such as Figure 1~4 As shown, the resonant acceleration sensor based on nano piezoelectric beams includes a substrate 1, a detection structure layer 2 and a cover plate 3;

[0055] The base 1 is made on the basis of a crystal orientation N-type single-polished silicon wafer. The top surface of the base 1 is a polished surface, and a movable cavity groove 11 is provided, and the center of the movable cavity groove 11 is provided with a lower limit position. slot 12;

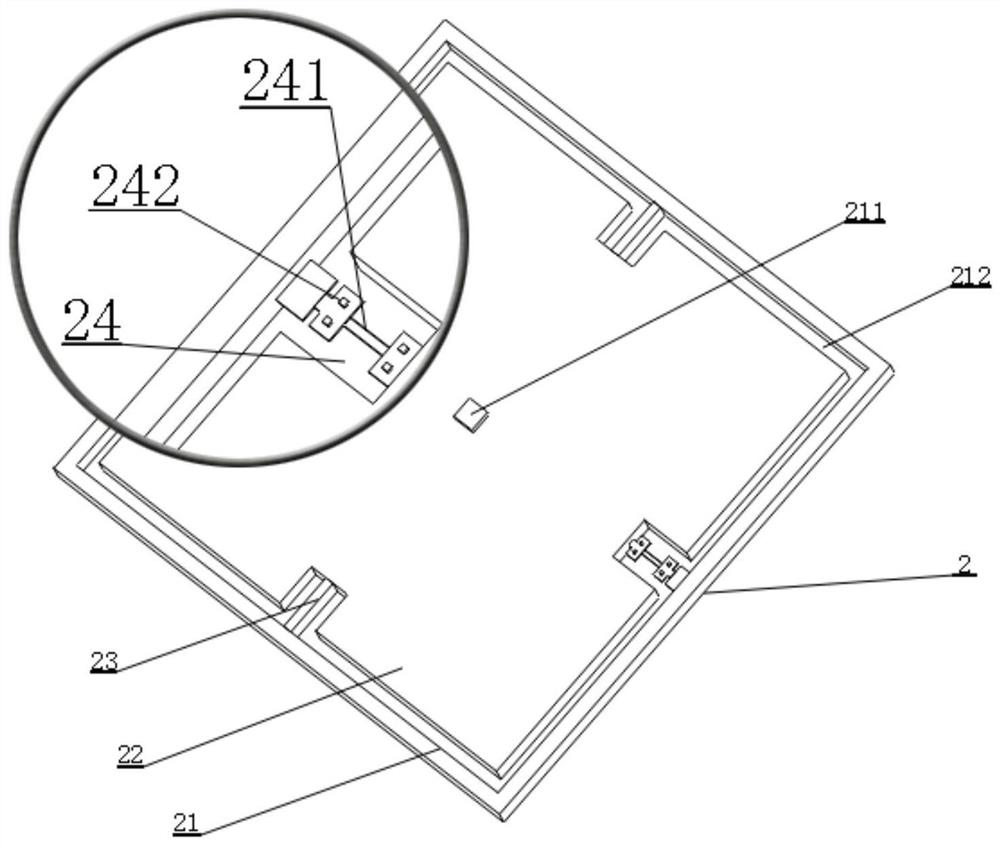

[0056] The detection structure layer 2 is made on the basis of a square double-polished SOI silicon wafer, and includes a square outer frame 21 and a square sensitive mass 22 located in the center of the outer frame 21, and the top surface and the center of the bottom surface of the sensitive mass 22 are respectively provided with Upper limit post 231 and lower limit post 211;

[0057] Taking the center of the sensitive mass 22 as the origin, the two sides of the sensitive mass 22 in the x-axis direction...

Embodiment 2

[0062] The present invention also includes the preparation method of the above-mentioned resonant acceleration sensor based on the nano piezoelectric beam, including the following steps: preparing the chip: taking a double-throwing SOI silicon wafer with a thickness of 100 μm and two crystal orientation N with a thickness of 30 μm Type single throw silicon wafer;

[0063] One-time photolithography: use standard semiconductor cleaning process to clean the double-polished SOI silicon wafer, and spin-coat photoresist on the surface of the double-polished SOI silicon wafer, the photolithography reveals the outer frame 21 and the sensitive mass 22, and the sensitive mass 22 Grooves are respectively photoetched in the middle of each side; as in Figure 5 shown.

[0064] Secondary photolithography: heat the top surface of the double-polished SOI silicon wafer at high temperature to grow a layer of silicon dioxide on the top surface, attach a layer of positive photoresist on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com