Polymer electrolyte composite membrane and preparation method thereof

An electrolyte membrane and polymer technology, applied in the field of lithium-ion batteries, can solve the problems of high internal resistance, low tensile strength, and difficulties in meeting the production process requirements of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

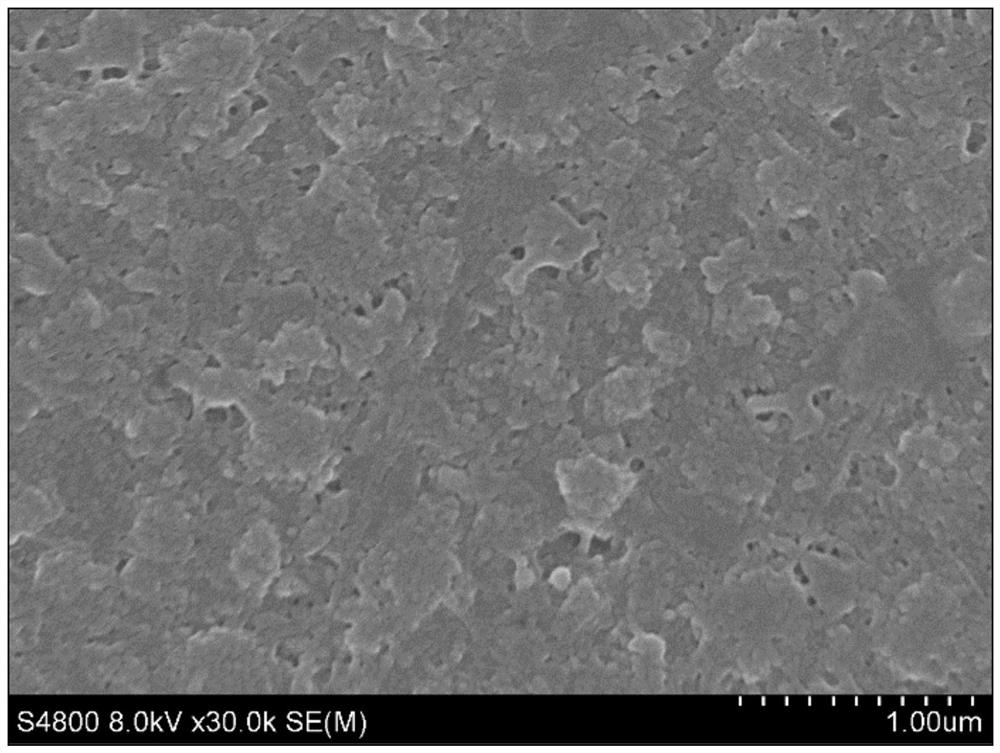

Image

Examples

preparation example Construction

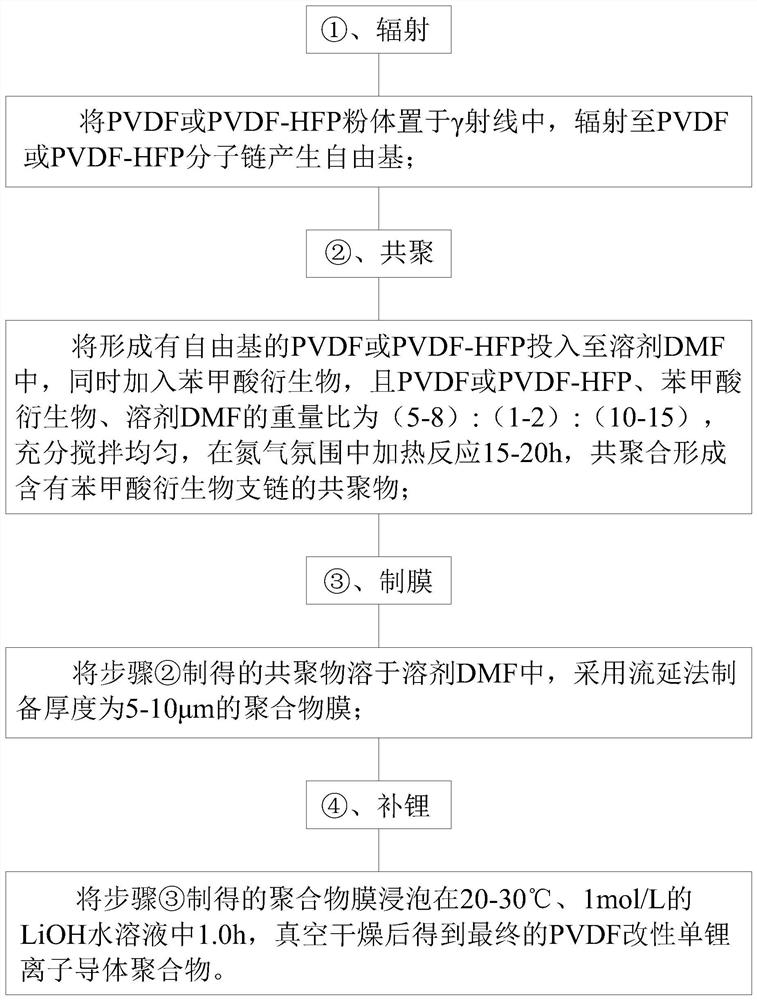

[0051] The preparation method of above-mentioned polymer a, see figure 1 , including the following steps:

[0052] ① Radiation: Put the PVDF resin powder in a test tube, seal it with nitrogen gas, and then put it into 60 Pre-irradiation in the Co irradiation room; the activity of the radiation source is 30000Ci, the dose rate is 200Gy / min, and the radiation promotes the generation of free radicals in the PVDF molecular chain;

[0053] ②. Copolymerization: put PVDF with free radicals into the solvent DMF, and add 4-vinylbenzoic acid at the same time, and the weight ratio of PVDF or PVDF-HFP, benzoic acid derivatives, and solvent DMF is 6:1:13, Thoroughly stir evenly, heat and react in a nitrogen atmosphere for 15 hours, and copolymerize to form a copolymer containing branched chains of benzoic acid derivatives;

[0054] ③, film making: the copolymer prepared in step ② is dissolved in the solvent DMF, and a polymer film with a thickness of 8 μm is prepared by casting method; ...

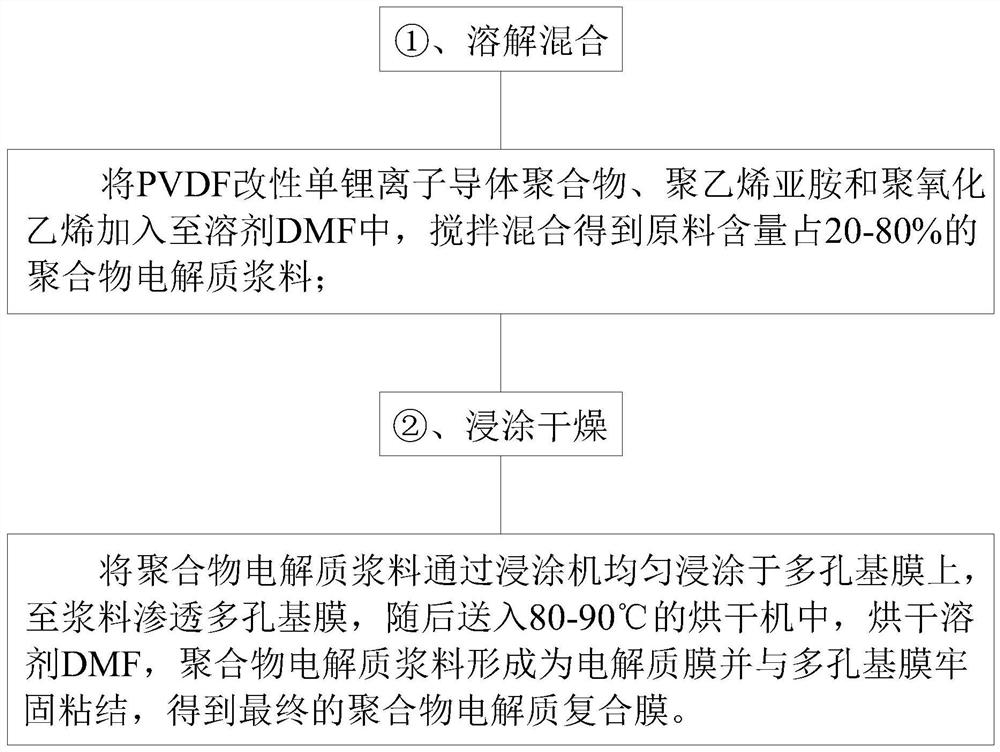

Embodiment 2-9

[0074] Examples 2-9 are all based on the method of Example 1, and the PVDF modified single lithium ion conductor polymer is adjusted, and Examples 2-9 correspond to polymers b-i respectively.

Embodiment 1

[0076] Examples 10-12 are all based on the method of Example 1, and polyethyleneimine is adjusted, and Examples 10-12 correspond to PEI-2, PEI-3 and PEI-4 respectively.

[0077] 2.4. Examples 13-15

[0078] Examples 13-15 are all based on the method of Example 1, and the polyethylene oxide is adjusted, and Examples 13-15 correspond to PEO-2, PEO-3 and PEO-4 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com