Silicon-carbon composite material, preparation method thereof, lithium battery negative electrode material and lithium battery

A technology of silicon-carbon composite materials and lithium batteries, applied in battery electrodes, carbon preparation/purification, secondary batteries, etc., can solve the problem of low surface loading, uneven carbon coating, and low compaction density of silicon-carbon materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

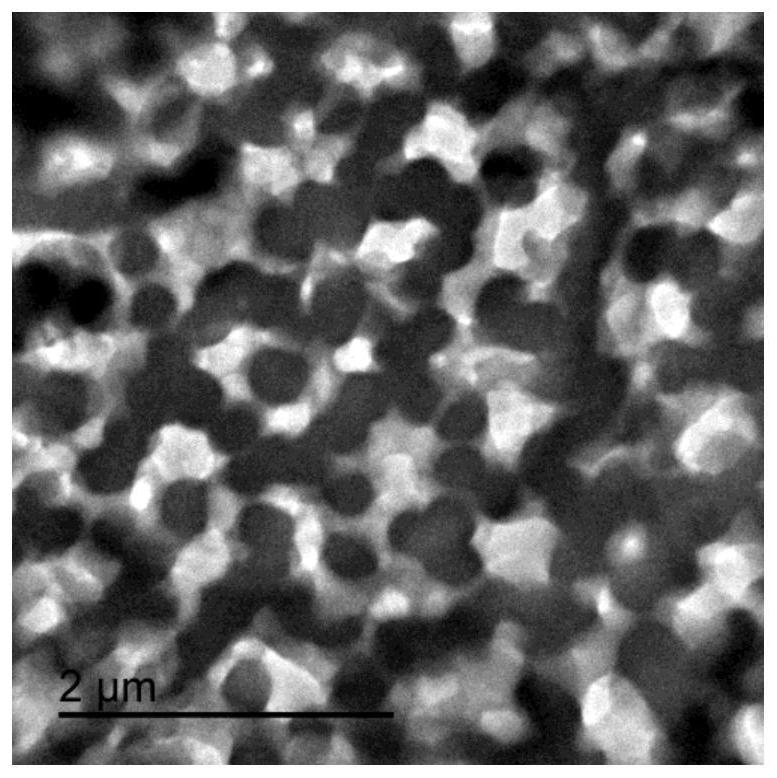

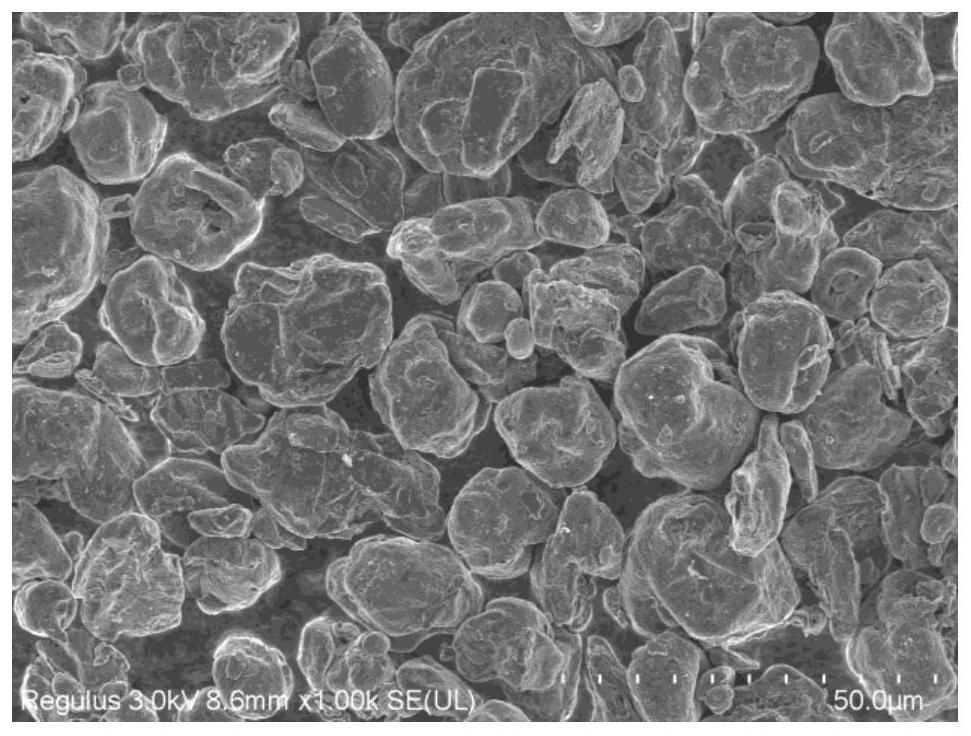

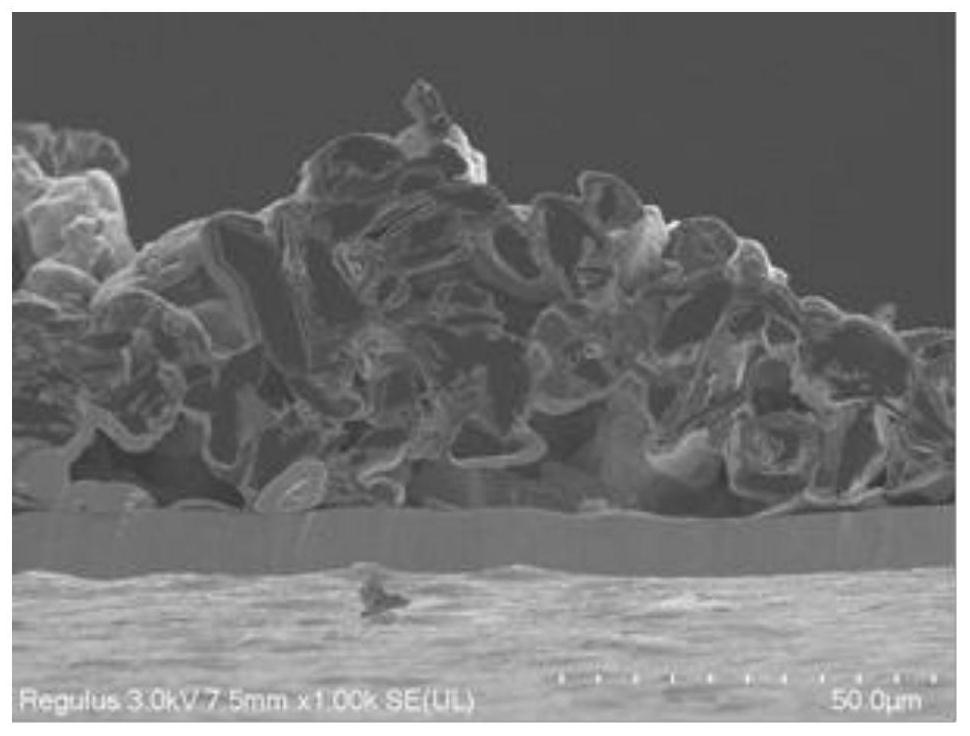

[0025] In a typical implementation of the present application, a method for preparing a silicon-carbon composite material is provided, which includes: step S1, mixing nano-silicon, carbon source, etchant, binder and solvent , to obtain the mixture; step S2, the mixture is subjected to a carbonization treatment to obtain a graphene-like carbon film-coated silicon material; step S3, the graphene-like carbon film-coated silicon material, carbon series conductive agent and polymer conductive agent are mixed 1. Compacting and molding to obtain a molding blank; and step S4, performing secondary carbonization treatment on the molding blank to obtain a silicon-carbon composite material; wherein, the etchant is an alkali metal salt.

[0026] The nano-silicon in the above-mentioned mixture of the present application reduces the temporary agglomeration between the nano-silicon to a certain extent under the dilution of the carbon source, etchant, binder and solvent, and then utilizes the e...

Embodiment 1

[0046] Add 300g of silicon powder into 4L of isopropanol, grind it with a pin-type dispersing mill until the particle D50 is 80-100nm, transfer the slurry to a nano-dispersing machine, add 45g PVB, 60g KCl, and 300g PVDF in sequence, and disperse for 30 minutes. Spray drying to obtain a mixture; the mixture is subjected to the first carbonization treatment at 800° C. for 2 hours under a nitrogen protective atmosphere to obtain a graphene-like carbon film-coated silicon material. Disperse the graphene-like carbon film-coated silicon material in 8% hydrochloric acid solution and stir for 2 hours to remove the potassium salt in the graphene-like carbon film-coated silicon material to obtain the acid-washed silicon-carbon material, and the pickled silicon-carbon After the material was washed with water, it was dried in an oven at 80°C for 12 hours to obtain a graphene-like carbon film-coated silicon material.

[0047] 100g of graphene-like carbon film-coated silicon material, 150g...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is that

[0050] KCl is 115g, and the silicon-carbon composite material is finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com