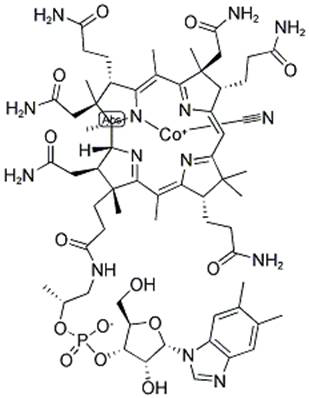

Preparation method of vitamin B12 crude product

A B12 and vitamin technology, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of easy contamination of centrifuges, affecting continuous operation, and high safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

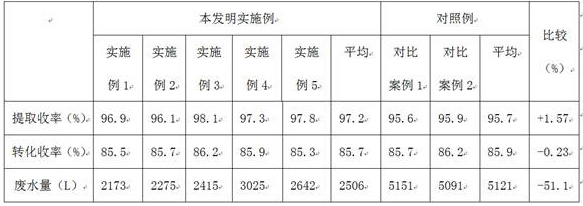

Examples

Embodiment 1

[0030] Put 180kg of the above filter residue (potency 560μg / g) into the solvent extraction tank, and add 630L of acetone composite solvent (acetone (V): iso Propanol (V): water (V) = 5.5:1.5:5.5), control the stirring speed at 60rpm, and carry out leaching at room temperature. After leaching for 3 hours, enter the plate frame for filtration, collect the filter residue, and carry out the second leaching as before. , combined the two extracts, and concentrated under reduced pressure to obtain 554 L of extract concentrate (titer 165 μg / ml).

[0031] Combine the extract and filtrate to 1251L (potency 180μg / ml), the volume of the mixed solution is 1805L (potency 175μg / ml), and the yield is 96.9%.

[0032] Put the above mixed solution into a macroporous resin adsorption column, analyze with 30% (v / v), 40% (v / v), and 50% (v / v) acetone aqueous solution in sequence, collect the analysis solution, concentrate under reduced pressure, and obtain adenoid The volume of the concentrated sol...

Embodiment 2

[0037] Put 180kg of the above filter residue (potency 560μg / g) into the solvent extraction tank, and add 720L of acetone composite solvent (acetone (V): iso Propanol (V): water (V) = 6.5:2.5:6.5), control the stirring speed at 60rpm, carry out leaching at room temperature, after leaching for 6 hours, enter the plate frame for filtration, collect the filter residue, and carry out the second leaching as before , combined the two extracts, concentrated under reduced pressure to obtain 604L of extract concentrate (potency 146μg / ml), combined filtrate 1251L (potency 180μg / ml), and mixed solution volume 1855L (potency 169μg / ml). The rate is 96.1%.

[0038]Put the above mixed solution into a macroporous resin adsorption column, analyze with 30% (v / v), 40% (v / v), and 50% (v / v) acetone aqueous solution in sequence, collect the analysis solution, concentrate under reduced pressure, and obtain adenoid Glycobalamin analytical concentrate volume 420L (titer 722μg / ml), yield 96.8%.

[003...

Embodiment 3

[0043] Put 180kg of the above filter residue (potency 560μg / g) into the solvent extraction tank, and add 810L of acetone composite solvent (acetone (v):iso Propanol (v): water (V) = 6.0:2.0:6.0), control the stirring speed at 60rpm, carry out leaching at room temperature, after leaching for 5 hours, enter the plate frame for filtration, collect the filter residue, and carry out the second leaching as before , combined the two extracts, concentrated under reduced pressure to obtain 694L of extract concentrate (potency 135μg / ml), combined filtrate 1251L (potency 180μg / ml), and mixed solution volume 1945L (potency 164μg / ml). The rate is 98.1%.

[0044] Put the above mixed solution into a macroporous resin adsorption column, analyze with 30% (v / v), 40% (v / v), and 50% (v / v) acetone aqueous solution in sequence, collect the analysis solution, concentrate under reduced pressure, and obtain adenoid Glycobalamin analytical concentrate volume 470L (titer 663μg / ml), yield 97.8%.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com