Preparation method of silane modified graphene, sheet metal part, air conditioner indoor unit and air conditioner

A silane modification, graphene technology, applied in air conditioning systems, space heating and ventilation, heating methods, etc., can solve problems such as poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation method of silane-modified graphene. Wherein, the preparation method adopts a one-pot method (carried out in a one-pot reaction furnace) to prepare silane-modified graphene, and the preparation process is simple and can be mass-produced.

[0040] Specifically, the preparation method of the silane-modified graphene that the present invention proposes comprises the following steps:

[0041] Add graphene oxide and solvent in the reactor;

[0042] Stir at room temperature for 12h-36h, ultrasonically oscillate for 30min-60min;

[0043] Add silane coupling agent in the reactor;

[0044] Raise the temperature to 50°C-200°C, stir and react for 12h-36h, wait until the mixture gradually changes from golden brown to dark brown, and stop the reaction.

[0045] In the embodiment of the present invention, the concentration of the graphene oxide is 0.2g / L-3g / L, and the weight ratio of the silane coupling agent to the graphene oxide is 1%-12%.

...

Embodiment 1

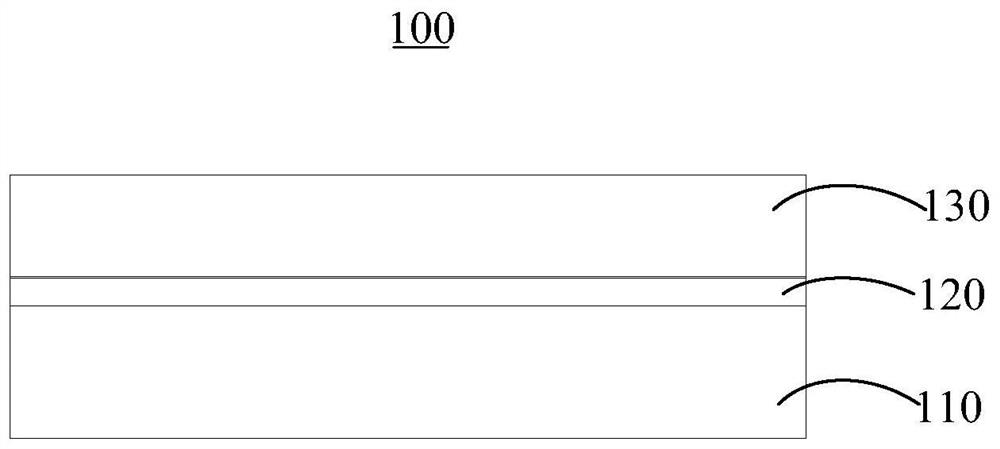

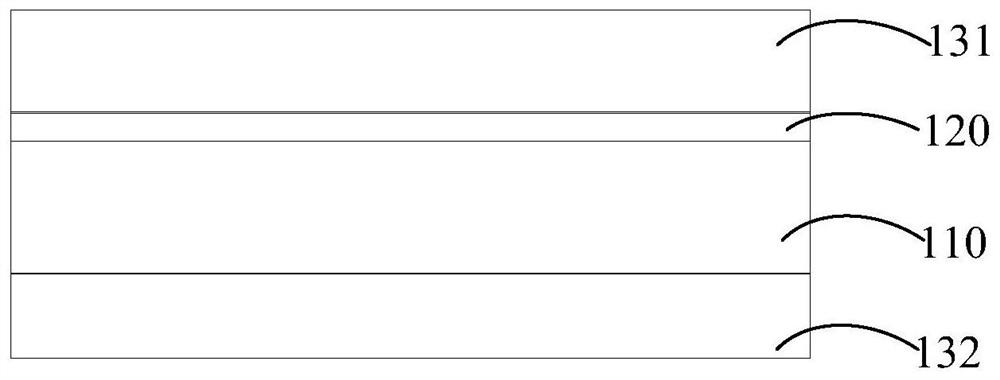

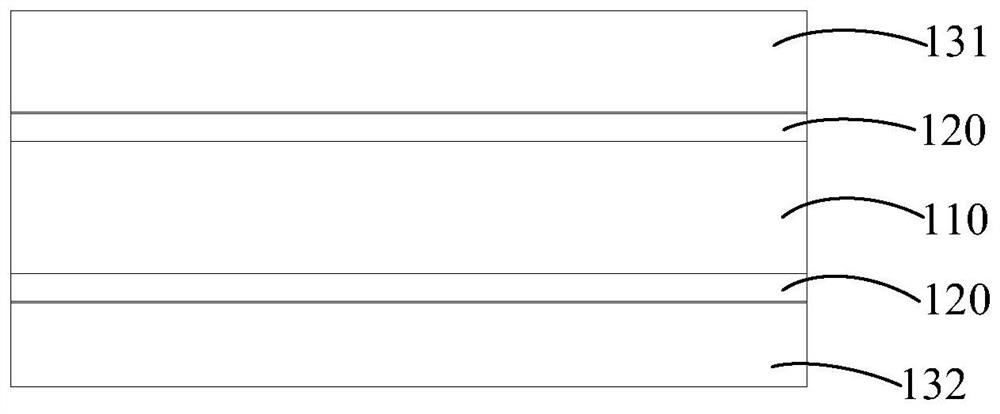

[0061] This embodiment provides a sheet metal part 100, including a metal plate 110, an anti-corrosion coating 130 and a silane-modified graphene coating 120, the anti-corrosion coating 130 is arranged on the metal plate 110; The modified graphene coating is sandwiched between the metal plate 110 and the anti-corrosion coating 130 .

[0062] In this embodiment, the preparation method of the silane-modified graphene: in a 1000ml flask, add 0.2g graphene oxide powder and 1L solvent (the concentration of graphene oxide is 0.2g / L), wherein the solvent Including xylene, butanol and benzyl alcohol, the volume ratio of the three is 3:0.8:0.2; magnetically stir the mixed solution for 24 hours, add water bath ultrasonic oscillation for 40 minutes (ultrasonic oscillation frequency is 37Hz, ultrasonic oscillation power is 50%), make graphite oxide Graphene powder is fully dispersed in the solvent, shaking the reaction bottle, no particles or flocculent aggregates can be observed with the...

Embodiment 2

[0064] This embodiment provides a sheet metal part 100, including a metal plate 110, an anti-corrosion coating 130 and a silane-modified graphene coating 120, the anti-corrosion coating 130 is arranged on the metal plate 110; The modified graphene coating is sandwiched between the metal plate 110 and the anti-corrosion coating 130 .

[0065] In this embodiment, the preparation method of the silane-modified graphene: in a 1000ml flask, add 0.8g graphene oxide powder and 1L solvent (the concentration of graphene oxide is 0.8g / L), wherein the solvent Including xylene, butanol and benzyl alcohol, the volume ratio of the three is 3:0.8:0.2; magnetically stir the mixed solution for 24 hours, add water bath ultrasonic oscillation for 40 minutes (ultrasonic oscillation frequency is 37Hz, ultrasonic oscillation power is 50%), make graphite oxide Graphene powder is fully dispersed in the solvent, shaking the reaction bottle, no particles or flocculent aggregates can be observed with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com