Impact-resistant interpenetrating network anticorrosive paint

An interpenetrating network, anti-corrosion coating technology, applied in anti-corrosion coatings, fire-retardant coatings, polyamide coatings, etc., can solve the problems of water resistance, easy yellowing, poor gloss and color retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

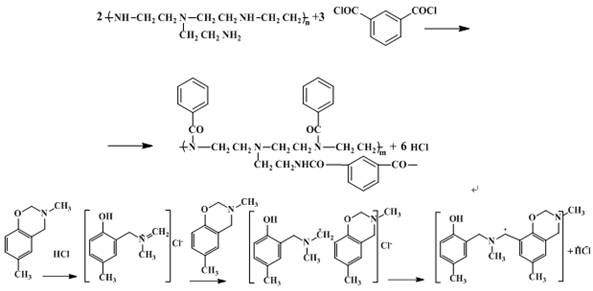

Method used

Image

Examples

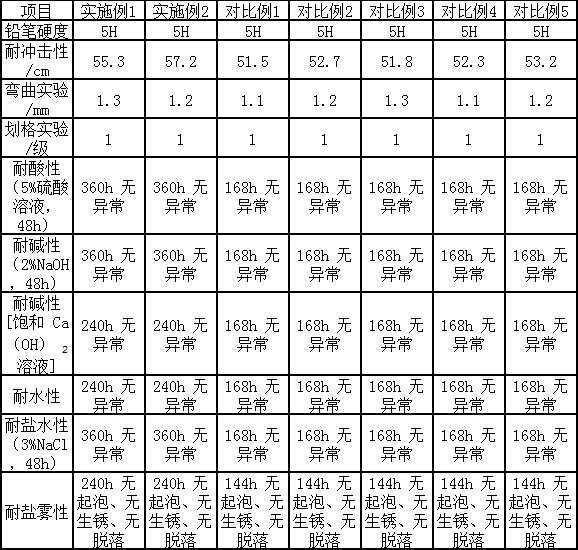

Embodiment 1

[0022] The coating includes an independently packaged paint base and an independently packaged curing agent slurry, and the coating is generated by mixing and stirring the two before use, wherein the mixing ratio of the independently packaged paint base and the independently packaged curing agent slurry is : Use after mixing according to the weight ratio of the paint base and the curing agent slurry of 10:0.9. The preparation method of the millbase comprises the following steps: (1) Preparation of modified benzoxazine: 12.7 parts of cardanol, 33 parts of formaldehyde aqueous solution with a mass fraction of 24%, 13.4 parts of 2,6-diisopropylaniline, 0.5 parts of lignin and 37 parts of toluene were placed in a reaction kettle with a condenser and a thermometer, and the electromagnetic stirring was carried out at room temperature for 15 minutes to fully mix, and the reaction was stirred at 80°C for 4 hours, and the product was dispersed in hexadioxide. Wash with ~6% ammonia solu...

Embodiment 2

[0024]The paint includes an independently packaged paint base and an independently packaged curing agent slurry, and the paint is generated by mixing and stirring the two before use, wherein the paint base is used as a paint material alone, according to the paint base 1. The weight ratio of the curing agent slurry is 10:0.8. Spray the curing agent slurry evenly on the surface of the paint.

[0025] The preparation method of the millbase comprises the following steps: (1) Preparation of modified benzoxazine: 10.4 parts of cardanol, 25-33 parts of formaldehyde aqueous solution with a mass fraction of 22%, 12.5 parts of 2,6-diisopropyl Aniline, 0.4 parts of lignin, and 33 parts of toluene are placed in a reaction kettle with a condenser and a thermometer, and electromagnetically stirred at room temperature for 10 minutes to make them fully mixed, stirred and reacted at 75°C for 2 to 4 hours, and the product is dispersed in hexadioxide , washed with 4% ammonia solution, then washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com