Preparation method for automobile plate spring

A technology of automobile plates and leaf springs, applied in the direction of manufacturing tools, heat treatment equipment, coatings, etc., can solve the problems of serious environmental pollution, high weight, and non-wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

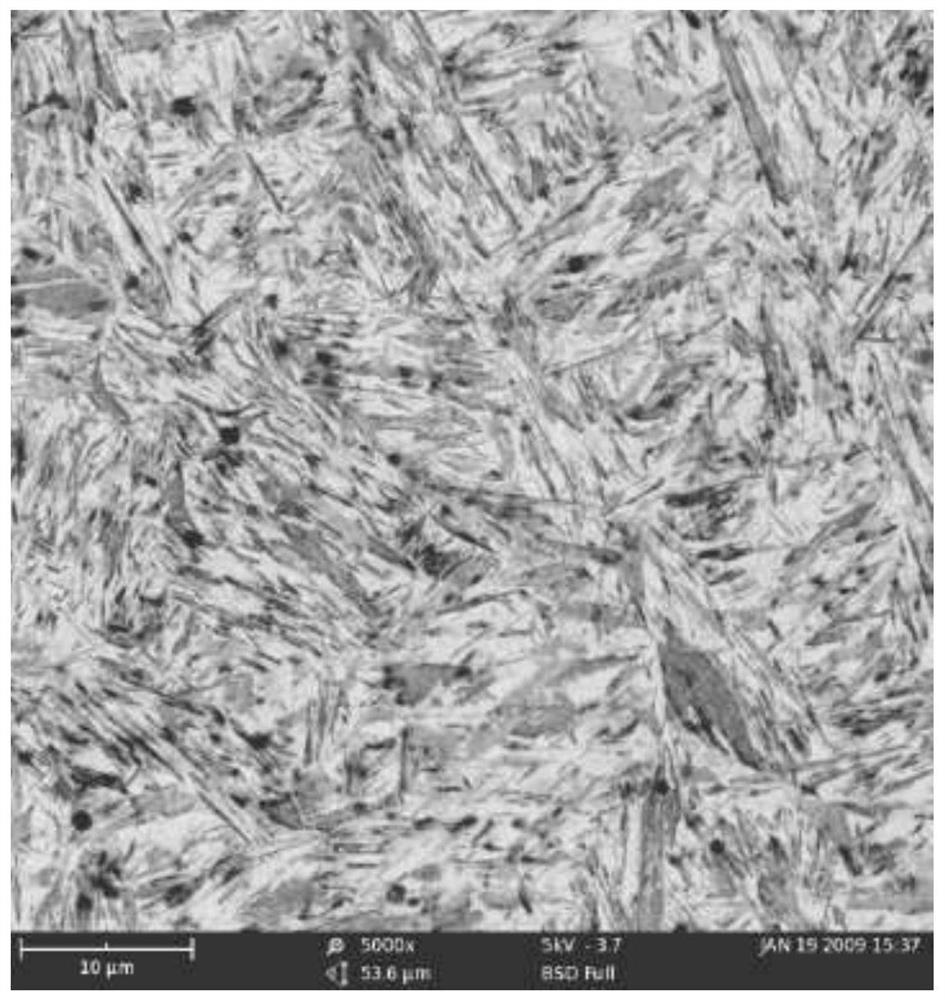

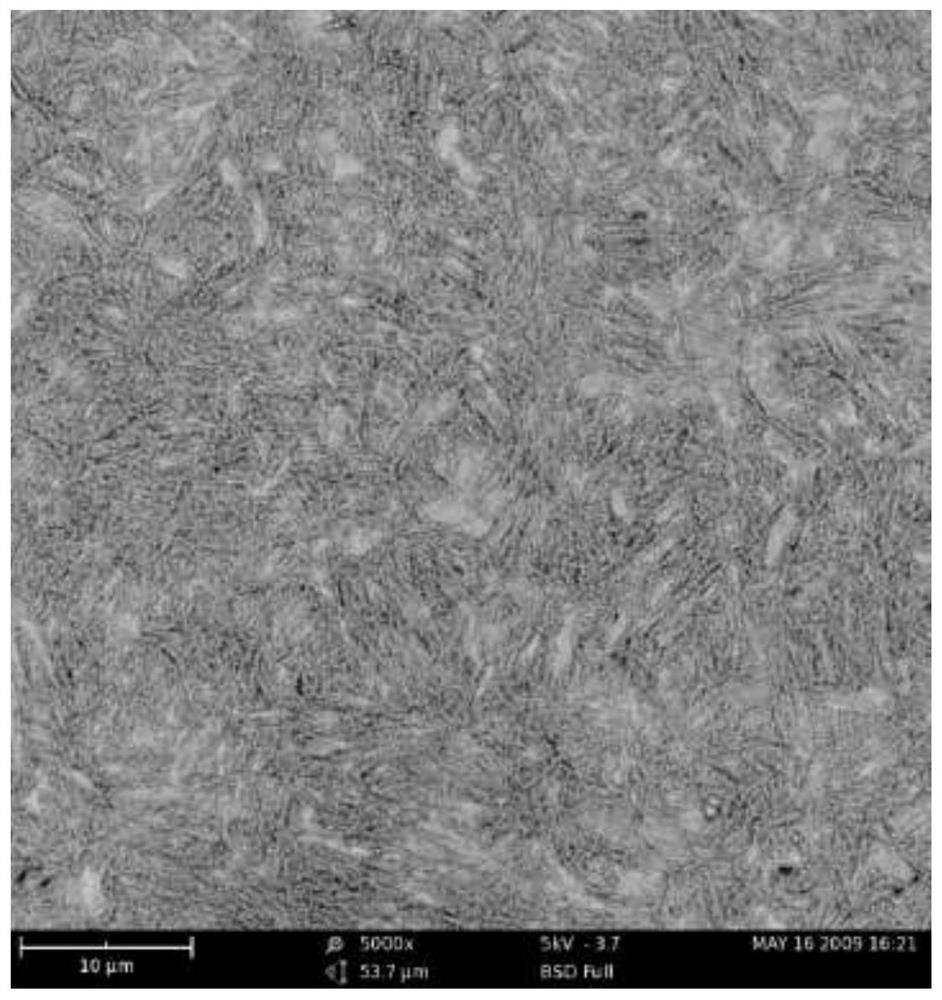

Image

Examples

preparation example Construction

[0031] The invention provides a technical solution: a method for preparing an automobile leaf spring. The automobile leaf spring is made of a spring steel billet containing molybdenum, vanadium, chromium and nickel elements, comprising the following steps:

[0032] Step S1, spring steel is forged to obtain a billet; melted in a vacuum electric furnace, then electroslag remelted under the protection of an inert gas, and then hot forged into a billet (initial forging temperature 1200°C, final forging temperature 1050°C);

[0033] Step S2, hot-rolling the spring steel billet into an automobile leaf spring steel plate with variable cross-section characteristics, and the hot-rolling temperature is 1200°C;

[0034] Step S3, performing ear rolling; keeping the leaf spring in a furnace at 1050° C. for 5-10 minutes, and then performing ear rolling;

[0035] Step S4, constant temperature treatment; the leaf spring after the ears are directly put into a heat treatment furnace at 860°C fo...

Embodiment 1

[0048] A method for preparing an automobile leaf spring. The automobile leaf spring is made of a spring steel billet containing molybdenum, vanadium, chromium, and nickel elements. The mass percentages of the spring steel billet components are: carbon C: 0.48%; silicon Si: 1.4% Manganese Mn: 0.80%; Molybdenum Mo: 0.15%; Vanadium V: 0.10%; Chromium Cr: 0.2%; Nickel Ni: 0.1%; Copper Cu: 0.08%; Aluminum Al: <0.09%; Phosphorus P: 0.009%; the balance is iron Fe. Weigh the cumulative sum of the above elements to be 100%, smelt in a vacuum electric furnace, and then go through electroslag remelting under the protection of inert gas, and then hot forge into billets (initial forging temperature 1200°C, final forging temperature 1050°C), take the forged and formed Spring steel blanks for automobile leaf springs are placed in a medium-frequency induction furnace and heated evenly to 1200°C, and then bent and molded on a die forging machine to obtain the radian and variable section size r...

Embodiment 2

[0052] A method for preparing an automobile leaf spring. The automobile leaf spring is made of a spring steel billet containing molybdenum, vanadium, chromium and nickel elements. The mass percentages of the spring steel billet components are: carbon C: 0.49%; silicon Si: 1.48% ; Manganese Mn: 0.85%; Molybdenum Mo: 0.16%; Vanadium V: 0.12%; Chromium Cr: 0.23%; Nickel Ni: 0.12%; Copper Cu: 0.09%; P: 0.008%; the balance is iron Fe. Weigh the cumulative sum of the above elements to be 100%, smelt in a vacuum electric furnace, and then go through electroslag remelting under the protection of inert gas, and then hot forge into billets (initial forging temperature 1200°C, final forging temperature 1050°C), take the forged and formed Spring steel blanks for automobile leaf springs are placed in a medium-frequency induction furnace and heated evenly to 1200°C, and then bent and molded on a die forging machine to obtain the radian and variable section size required for automobile leaf ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com