Dispersion method of nanoscale inorganic particles suitable for composite electrodeposition

A composite electrodeposition, inorganic particle technology, used in electrolytic coatings, coatings, etc., can solve the problems of complex operation, enhanced dispersion, and little consideration of particle application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

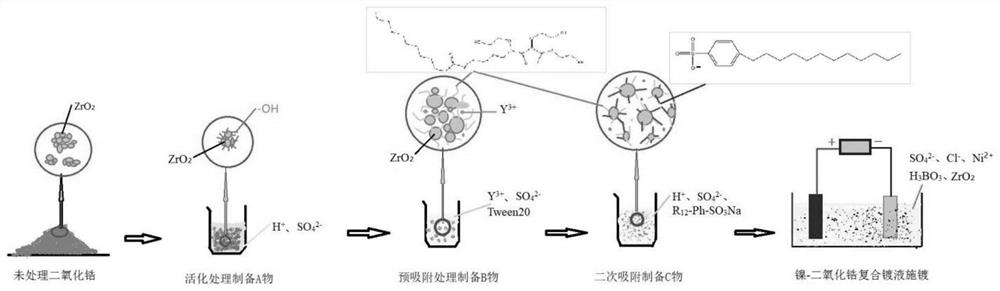

[0048] Taking zirconia particles as an example, a kind of nano-scale inorganic particle dispersion method of the present invention is used to improve the dispersion, such as figure 1 As shown, the specific steps are as follows:

[0049] In the first step, the zirconium dioxide particles are activated to prepare zirconium dioxide (substance A) containing hydroxyl groups on the surface.

[0050] Add 600nm zirconia particles into a sulfuric acid solution with a temperature of 25° C. and a concentration of 5% by mass to activate for 10 minutes to obtain zirconia (A substance) containing hydroxyl groups on the surface;

[0051] In the second step, the zirconium dioxide containing hydroxyl groups on the surface is pre-adsorbed in the treatment solution A to prepare zirconium dioxide (substance B) containing Tween 20 long-chain groups on the surface.

[0052] The composition of treatment liquid A is 40% (weight part) Tween 20 (pre-adsorbent), 5% (weight part) yttrium sulfate (auxili...

Embodiment 2

[0068] A method for dispersing nanoscale inorganic particles, the specific steps are as follows:

[0069] In the first step, silicon carbide particles are activated to prepare silicon carbide with hydroxyl groups on the surface.

[0070] Adding 50nm silicon carbide particles to a hydrochloric acid solution with a temperature of 60°C and a mass percent concentration of 5% for 20 minutes to obtain silicon carbide with hydroxyl groups on the surface;

[0071] The second step is to pre-adsorb the silicon carbide containing hydroxyl groups on the surface in the treatment solution A to prepare silicon carbide containing hydroxyl groups and polyoxyethylene 40 long-chain groups on the surface.

[0072] The composition of treatment liquid A is 60% (weight part) polyoxyethylene 40 stearate (pre-adsorbent), 0.1% (weight part) cerium sulfate (auxiliary adsorbent), surplus is water, and pH is 7, Mix silicon carbide with hydroxyl groups on the surface and treatment solution A at a mass rat...

Embodiment 3

[0088] A method for dispersing nanoscale inorganic particles, the specific steps are as follows:

[0089] In the first step, boron nitride particles are activated to prepare boron nitride with hydroxyl groups on the surface.

[0090] adding 900nm boron nitride particles into a sulfuric acid solution with a temperature of 40°C and a concentration of 20% for 15 minutes to activate boron nitride with hydroxyl groups on the surface;

[0091] In the second step, the boron nitride containing hydroxyl groups on the surface is pre-adsorbed in the treatment solution A to prepare boron nitride containing hydroxyl groups and Tween 40 long-chain groups on the surface.

[0092] The composition of treatment liquid A is 50% (weight part) Tween 40 (pre-adsorbent), 2% (weight part) cobalt sulfate (auxiliary adsorbent), surplus is water, and pH is 6, will surface hydroxyl-containing Boron nitride and treatment solution A were mixed at a mass ratio of 100:100, and the ultrasonic treatment time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com