A kind of flame-retardant and sound-insulating composite curtain wall

A curtain wall and composite layer technology, applied in the direction of sound insulation, walls, insulation layers, etc., can solve the problems of poor sound insulation effect, not well blocked, heavy weight of stone curtain wall, etc., to improve flame retardancy and sound insulation performance, good Thermal stability, the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

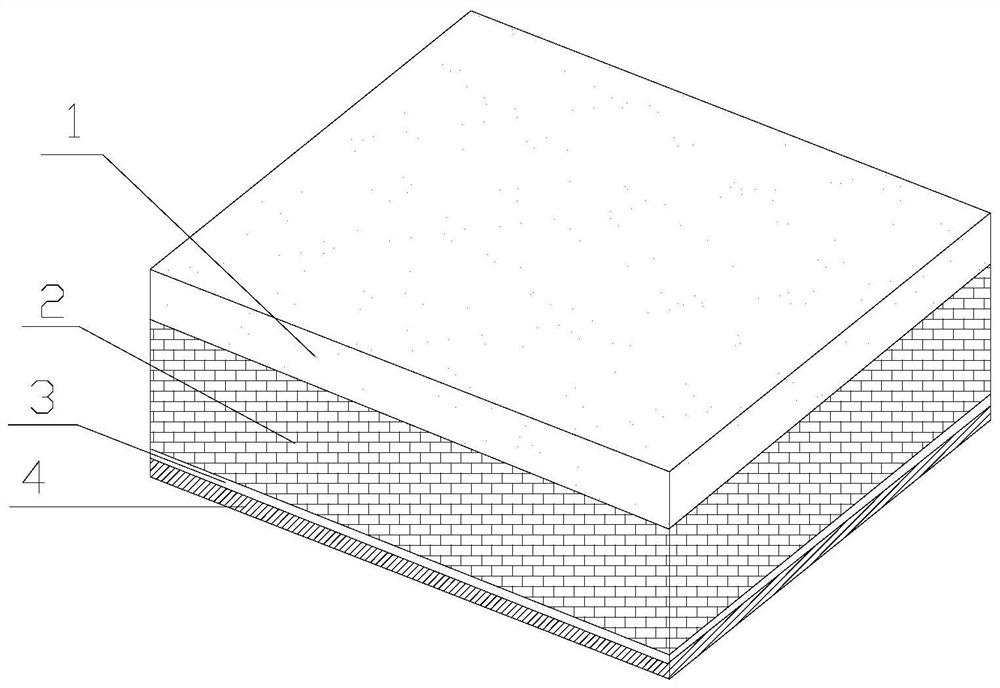

[0030] The preparation method of the above-mentioned flame-retardant and sound-insulating composite curtain wall specifically includes the following steps:

[0031] S1. Mix the components of the PET / PVC flame-retardant composite layer 2 according to the weight ratio and put them in an oven at 100°C to dry for 4 hours, then add them to the internal mixer, set the temperature at 150-170°C, and banbury The time is 15-20min. After the internal mixing is completed, put it into a hot press, keep the pressure at 15MPa, and carry out hot-press molding at a temperature of 220-230°C to obtain the required PET / PVC flame-retardant composite layer 2 .

[0032] S2. Heat the PET / PVC flame-retardant composite layer 2 in step (1) to 60-70°C, keep it warm for 2 hours, and then embed it in the aluminum plate outer frame 1, and coat the PET / PVC flame-retardant composite layer with an organic adhesive. The contact surfaces of the composite layer 2 and the aluminum frame 1 are bonded and compacted....

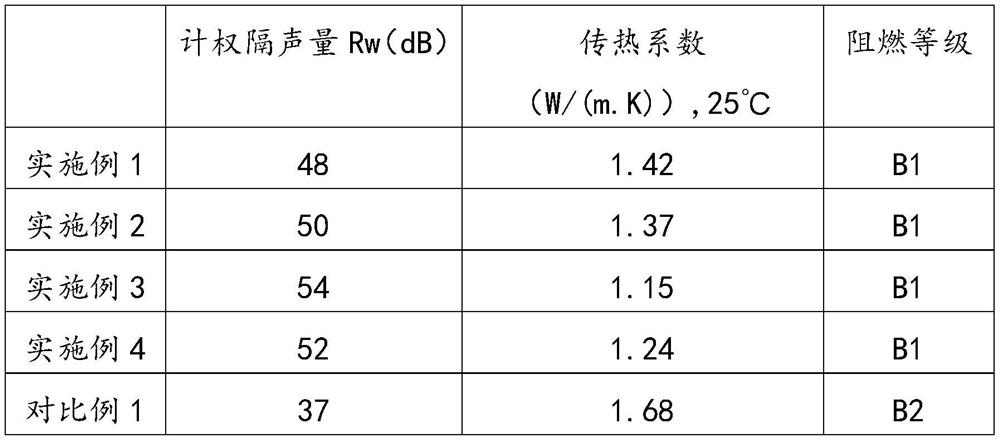

Embodiment 1

[0038] Example 1: The composition and preparation method of the flame-retardant and sound-insulating composite curtain wall are as above.

[0039] In the composition of the flame-retardant and sound-insulating composite curtain wall in this embodiment 1, the PET / PVC flame-retardant composite layer is composed of the following components by weight: 35 parts of PET, 20 parts of PVC, 22 parts of glass fiber, 6 parts of plasticizer, and 9 parts of titanium dioxide , 7 parts of BDP, 0.5 parts of TPP and 0.5 parts of calcium stearate.

[0040] In the composition of the flame-retardant and sound-insulating composite curtain wall in Example 1, the ceramic layer consists of the following ingredients in parts by weight: 86 parts of alumina, 4 parts of titanium dioxide, 5 parts of yttrium oxide, 3 parts of binder and 2 parts of ceramic dispersant. Wherein, the binder is polyvinyl butyral, and the ceramic dispersant is polyethylene glycol. The specific preparation method of the material ...

Embodiment 2

[0045] Example 2: The composition and preparation method of the flame-retardant and sound-insulating composite curtain wall are as above.

[0046] In the composition of the flame-retardant and sound-insulating composite curtain wall in this embodiment 2, the PET / PVC flame-retardant composite layer is composed of the following components by weight: 50 parts of PET, 12 parts of PVC, 20.2 parts of glass fiber, 5 parts of plasticizer, and 6 parts of titanium dioxide , 5 parts of BDP, 1 part of TPP and 0.8 parts of calcium stearate.

[0047] In the composition of the flame-retardant and sound-insulating composite curtain wall in Example 2, the ceramic layer consists of the following ingredients in parts by weight: 90 parts of alumina, 3 parts of titanium dioxide, 4 parts of yttrium oxide, 2 parts of binder and 1 part of ceramic dispersant. Wherein, the binder is polyvinyl butyral, and the ceramic dispersant is polyethylene glycol. The specific preparation method of the material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com