Method for forming cantilever beam probe based on femtosecond laser and high temperature and cantilever beam probe

A cantilever beam probe, femtosecond laser technology, applied in scanning probe technology, scanning probe microscopy, processes for producing decorative surface effects, etc., can solve complex manufacturing processes, low molding efficiency, and experimental equipment. expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

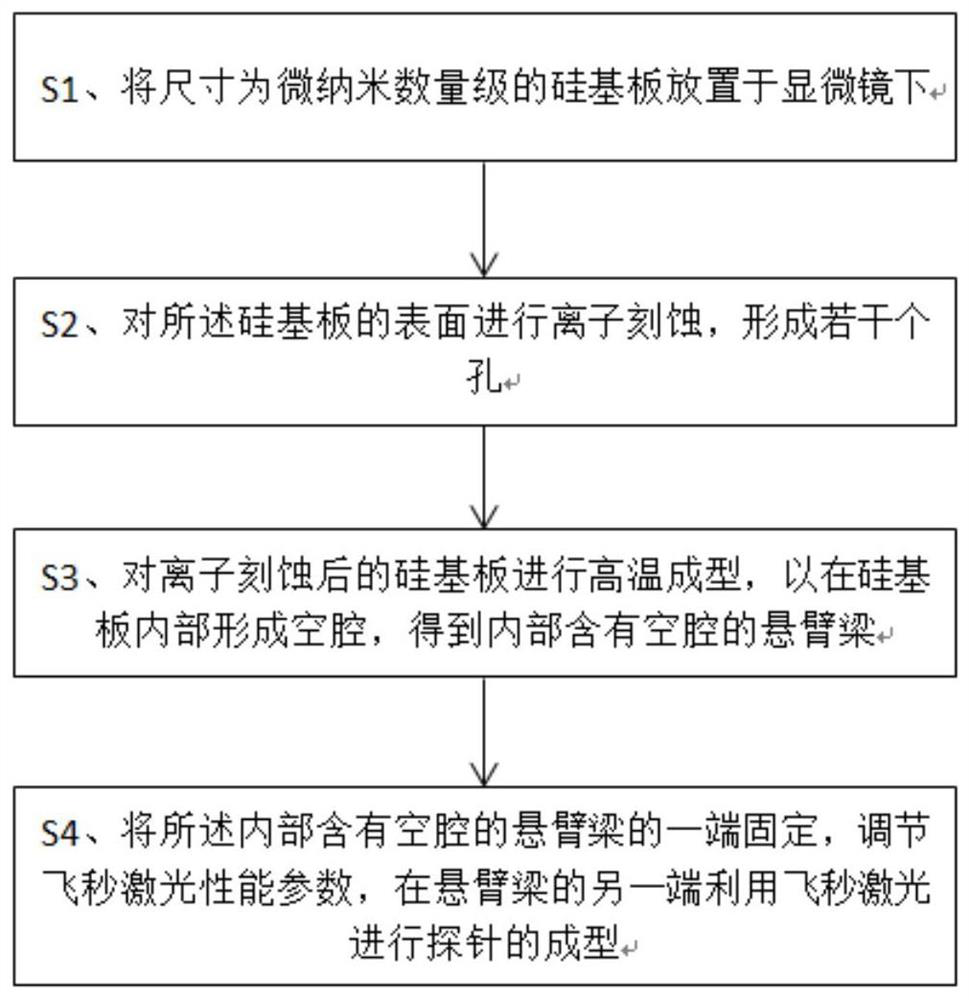

[0035] refer to figure 1 , 2 , 3, 4, 5 This embodiment provides a method based on femtosecond laser and high temperature forming cantilever beam probe, including steps:

[0036] S1. Place the silicon substrate 1 with a size on the order of micro-nanometers under a microscope;

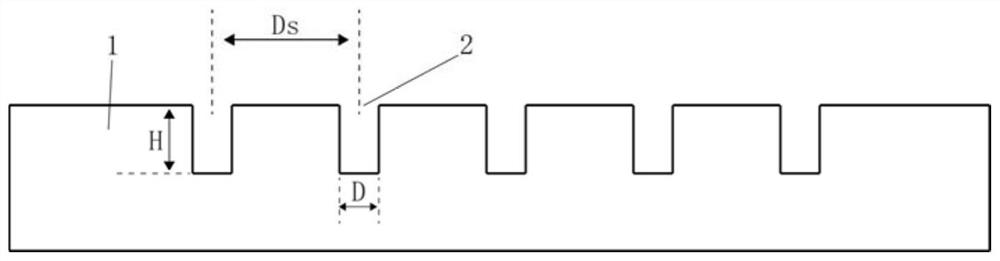

[0037] S2. Perform ion etching on the surface of the silicon substrate 1 to form several holes 2;

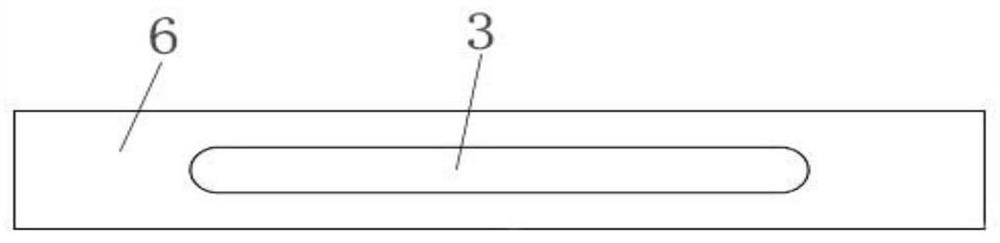

[0038] S2. Perform high-temperature molding on the silicon substrate 1 after ion etching to form a cavity 3 inside the silicon substrate 1 to obtain a cantilever beam 6 containing the cavity 3 inside;

[0039] S4. Fix one end of the cantilever beam 6 containing the cavity 3 inside, adjust the performance parameters of the femtosecond laser 4, and use the femtosecond laser 4 to shape the probe at the other end of the cantilever beam 6.

[0040] The micro-cantilever beam probe is the most important part of the micro-sensor, and it is generally prepared by low-pressure chemical vapor deposition, chemical ...

Embodiment 2

[0046] refer to Figure 5 , the present invention also provides a cantilever beam probe 8, using the preparation method as described in Embodiment 1, the cantilever beam 6 of the cantilever beam probe 8 contains a cavity 3, thus improving the resonance of the cantilever beam probe 8 frequency, so that the detection accuracy of the cantilever beam probe 8 becomes higher.

[0047] refer to Figure 6 , the working principle of the cantilever beam probe 8 of the present invention is: the laser emitter 9 emits laser light to the cantilever beam probe 8, and the laser light is irradiated to the photodetector 10 after reflection, because when the cantilever beam probe 8 contacts the object 11 , the probe 7 will produce a slight deformation, so the deflection of the cantilever beam 6 will also be slightly deformed. At this time, the light beam irradiated to the photodetector 10 by reflection produces an offset, so that the cantilever beam 6 can be deduced Elastic deformation Δx, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com