Method for synthesizing large-grain Beta molecular sieve by temperature programming method

A temperature-programmed, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, which can solve problems such as small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

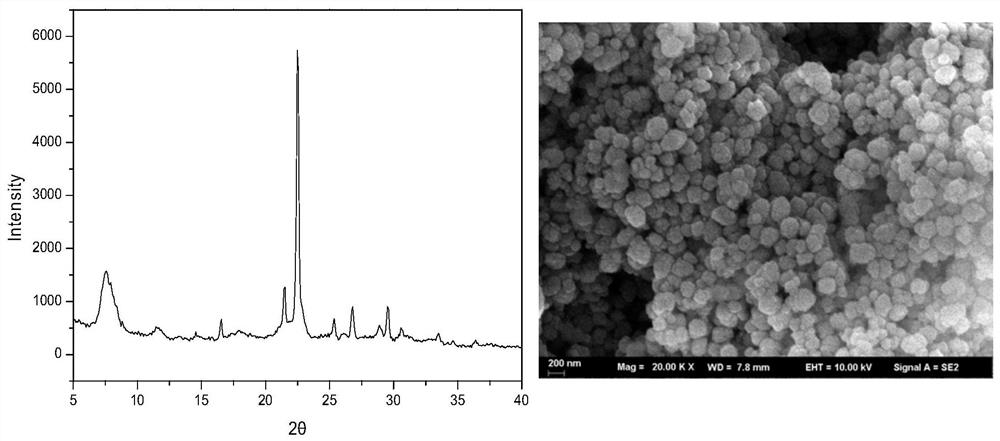

Embodiment 1

[0034] Add 6.0g KOH to 50.2g distilled water, stir until clear solution, then add 4.0g NaAlO 2 , stirred until clarified, slowly added 100g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; weighed a certain amount of tetraethylammonium hydroxide and tetraethylammonium bromide, and added Tetraethylammonium ions and SiO in silicate gels 2 The mass ratio of the above-mentioned template agent is 0.25, and the above-mentioned template agent is dissolved in 30.8g of deionized water and stirred until it is completely dissolved to obtain a mixed solution B. Under stirring conditions, the solution B is slowly added to the A gel to make the mixture uniform, and finally the mixture is transferred to In a polytetrafluoroethylene-lined stainless steel crystallization kettle, the temperature was raised from room temperature to 130°C at a rate of 5°C / hour, and then crystallized at 130°C for 120 hours; the product was separated to obtain Beta ...

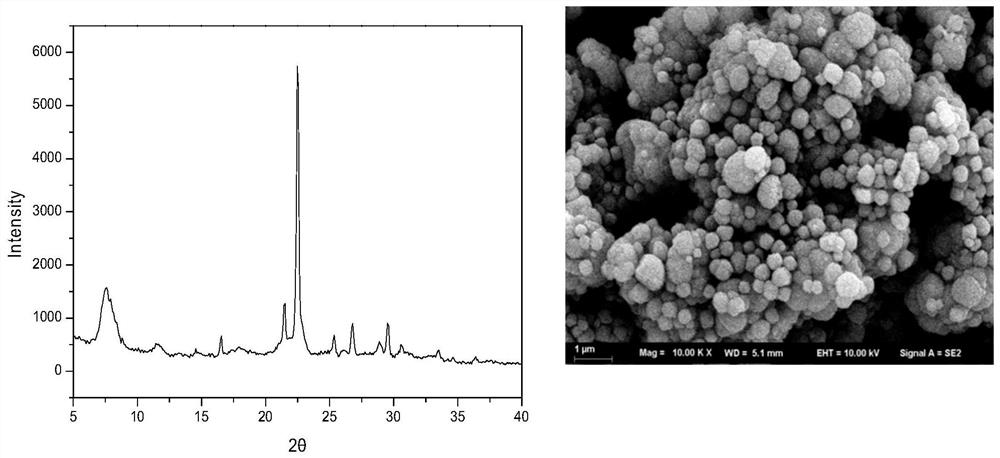

Embodiment 2

[0038] Add 6.5g KOH to 50.2g distilled water, stir until clear solution, then add 4.0g NaAlO 2 , stirred until clarified, slowly added 100g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; weighed a certain amount of tetraethylammonium hydroxide and tetraethylammonium bromide, and added Tetraethylammonium ions and SiO in silicate gels 2 The mass ratio of the template agent is 0.20. Dissolve the above-mentioned template agent in 30.8g of deionized water and stir until it is completely dissolved to obtain a mixed solution B. Slowly add solution B to A gel under stirring conditions to make the mixture uniform, and finally transfer the mixture into In a polytetrafluoroethylene-lined stainless steel crystallization kettle, the temperature was raised from room temperature to 130°C at a rate of 5°C / hour, and then crystallized at 130°C for 120 hours; the product was separated to obtain Beta molecular sieve solid and mother liquor, and ...

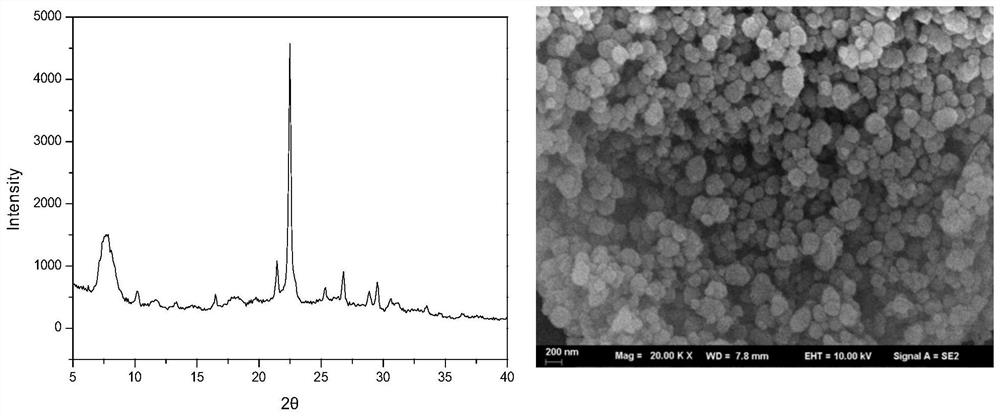

Embodiment 3

[0042] Add 7.6g KOH to 50.2g distilled water, stir until clear solution, then add 4.0g NaAlO 2 , stirred until clarified, slowly added 100g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; weighed a certain amount of tetraethylammonium hydroxide and tetraethylammonium bromide, and added Tetraethylammonium ions and SiO in silicate gels 2 The mass ratio of the above-mentioned template agent is 0.25, and the above-mentioned template agent is dissolved in 30.8g of deionized water and stirred until it is completely dissolved to obtain a mixed solution B. Under stirring conditions, the solution B is slowly added to the A gel to make the mixture uniform, and finally the mixture is transferred to In a polytetrafluoroethylene-lined stainless steel crystallization kettle, the temperature was raised from room temperature to 130°C at a rate of 5°C / hour, and then crystallized at 130°C for 120 hours; the product was separated to obtain Beta ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com