Non-fluorite mineralizer applicable to production of white portland cement

A white silicate and mineralizer technology, applied in the field of new materials, can solve the problems that the production of white cement with impurity content cannot be promoted, it is difficult to balance energy saving and consumption reduction with product performance, and reduce the whiteness of white cement products. Achieve the effects of quality performance improvement, production cost increase, and lower firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

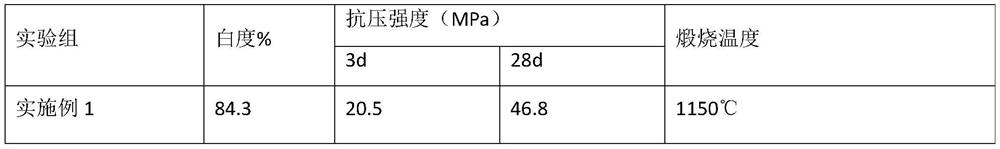

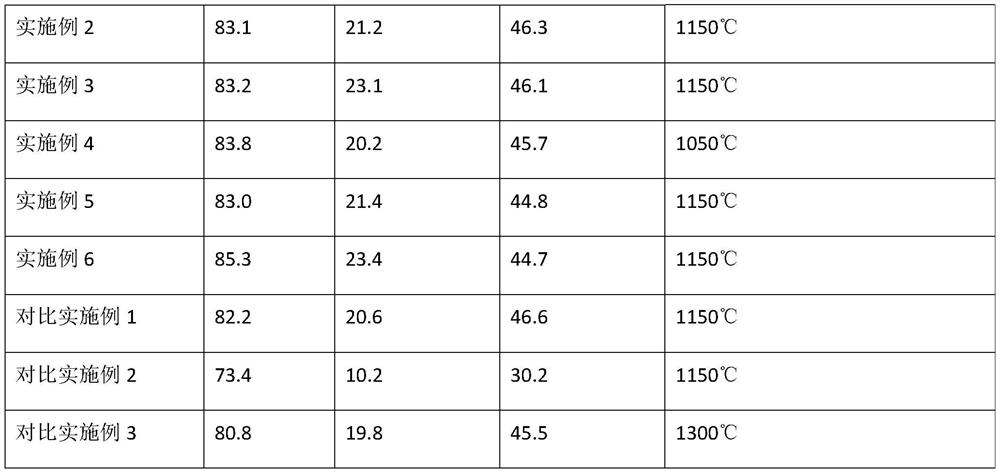

Examples

Embodiment 1

[0038] A non-fluorite type mineralizer preparation method suitable for white Portland cement, the steps are as follows:

[0039] (1) select low-iron barium slag, phosphorus slag and white slag as mineralizer raw material, weigh by the weight ratio of low-iron barium slag 40%, phosphorus slag 20%, white slag 40%;

[0040] (2) Aluminum chloride, oxalic acid and water are prepared into a solution according to the mass ratio of 1:4:20 to obtain the iron removal solution;

[0041] (3) Add the low-iron barium slag and phosphorus slag in step (1) into the iron removal solution (mass ratio 1:10), stir and react for 30 minutes, filter, wash with water, and dry to obtain the two industrial iron-removing products. waste residue;

[0042] (4) mixing the two kinds of industrial waste slag after iron removal in step (3) with the white slag in step (1), and passing through a 200-mesh sieve to obtain the finished product of the mineralizer;

[0043] (5) Weigh the finished mineralizer produc...

Embodiment 2

[0046] A kind of non-fluorite class is suitable for the preparation method of mineralizer of white portland cement, with example 1, difference is that step (1) mixing material ratio is: according to low-iron barium slag 35%, phosphorus slag 25%, The weight ratio of white slag 40% is weighed.

Embodiment 3

[0048] A non-fluorite type mineralizer preparation method suitable for white Portland cement, the same as Example 1, the difference is that the step (1) mixture ratio is: according to the low-iron barium slag 25%, phosphorus slag 30%, The weight ratio of white slag 45% is weighed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com