Water-absorbing controlled-release film for agilawood formation and method for producing agilawood

A water-absorbing, controlled-release membrane technology, applied in the field of agarwood, can solve the problems of not being able to fully tap the advantages of agarwood biological resources, and achieve the effects of reducing the frequency of manual operations, reducing costs, and improving utilization and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

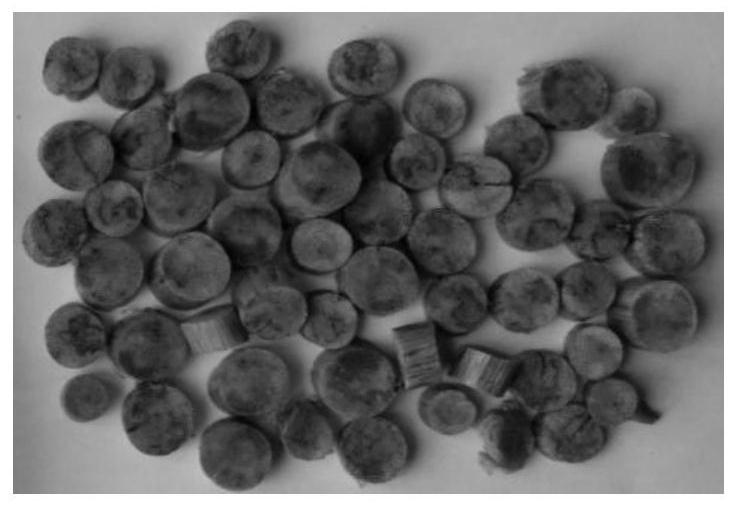

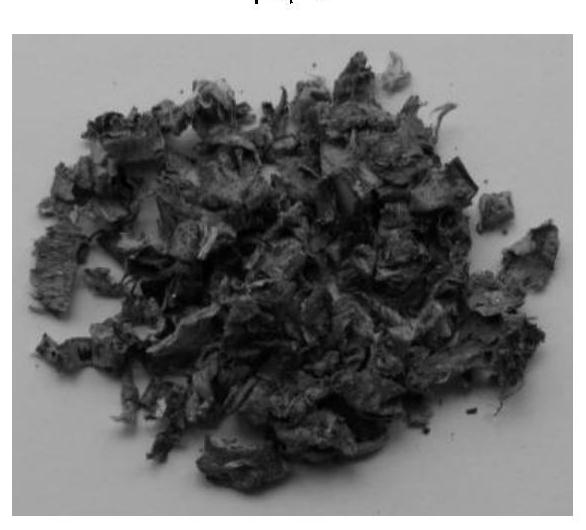

Image

Examples

Embodiment 1

[0049] The water-absorbing controlled-release film for agarwood in this example is mainly made of the following raw materials in parts by mass: water-absorbing polymer material 20, agarwood inducer nano-controlled release microspheres 6, basement film 50, and phytonutrients 2. Organic acid 0.5, water 700.

[0050] in:

[0051] The water-absorbing polymer material is konjac glucomannan grafted acrylic acid.

[0052] The base film is vinyl acetate-ethylene copolymer emulsion (EVA).

[0053] The agarwood inducer nano controlled-release microspheres are polyethylene glycol (PEG)-polycaprolactone (PCL)-methyl jasmonate.

[0054] The phytonutrients are based on the general liquid fertilizer formula of the conventional Japanese garden test, adding Bacillus and EDTA.

[0055] The organic acids are malic acid and citric acid.

[0056] The method for producing agarwood by using the water-absorbing controlled-release film to coat the trunk of agarwood species comprises the following ...

Embodiment 2

[0061] The water-absorbing controlled-release film for agarwood in this example is mainly made of the following raw materials in parts by mass: 10 parts of water-absorbing polymer materials, 5 parts of nano-controlled release microspheres of agarwood inducer, and 60 parts of EVA base film parts, 2 parts of phytonutrients, 0.15 parts of organic acid, and 500 parts of water.

[0062] in:

[0063] The water-absorbing polymer material is starch-grafted acrylic acid.

[0064] The base film is vinyl acetate-ethylene copolymer emulsion (EVA).

[0065] The agarwood inducer nano controlled-release microspheres are polyethylene glycol (PEG)-polycaprolactone (PCL)-methyl jasmonate.

[0066] Phytonutrients: On the basis of the general liquid fertilizer formula of conventional Japanese garden trials, several trace elements such as ascorbic acid, sodium nitrophenolate, humic acid and organic selenium are added.

[0067] The organic acid is salicylic acid.

[0068] The method for produci...

Embodiment 3

[0073] The water-absorbing controlled-release film for agarwood in this example is mainly made of the following raw materials in parts by mass: 30 parts of water-absorbing polymer materials, 10 parts of nano-controlled release microspheres of agarwood inducer, and 40 parts of base film , 1 part of phytonutrients, 0.8 parts of organic acids, and 900 parts of water.

[0074] in:

[0075] The water-absorbing polymer material is starch-grafted acrylic acid.

[0076] The base film is vinyl acetate-ethylene copolymer emulsion (EVA).

[0077] The agarwood inducer nano controlled-release microspheres are polyethylene glycol (PEG)-polycaprolactone (PCL)-methyl jasmonate.

[0078] The phytonutrients are added (commercially available) EM bacteria agent on the basis of the general liquid fertilizer formula of the conventional Japanese garden test.

[0079] The organic acid is citric acid.

[0080] The method for producing agarwood by using the water-absorbing controlled-release film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com