Nano TiO2 powder super-hydrophobic coating material as well as preparation method and application thereof

A super-hydrophobic coating and powder technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve problems such as environmental hazards, high cost of fluorine-containing substances, and poor hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

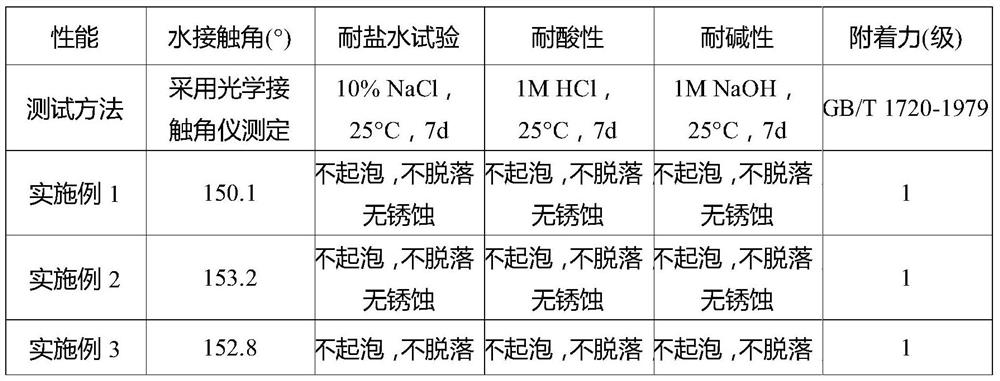

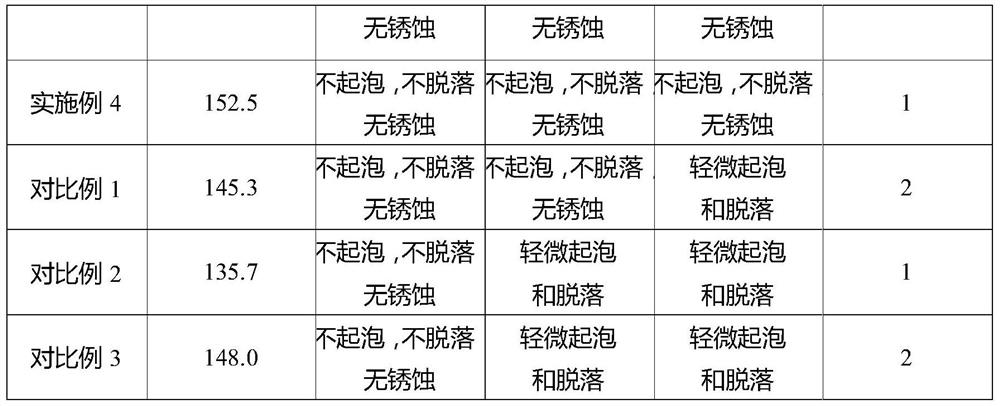

Examples

Embodiment 1

[0023] The preparation step of superhydrophobic coating material comprises the following:

[0024] 8 parts nano-TiO 2 The powder was added to 5 times the amount of ethanol-water mixture with a volume ratio of 1:1, ultrasonically dispersed and then stirred for 1 h, and the temperature was kept at 60°C. Add a small amount of triethylamine, then slowly add 1 part of ethanol solution of silane coupling agent dropwise, and fully react for 2 hours under rapid stirring conditions. After the reaction is completed, age at room temperature, filter with suction, wash with ethanol, and dry at 80°C to obtain the improved Nano-TiO 2 powder.

[0025] Add 80 parts of polyurethane and 10 parts of terpene resin to 80 parts of ethanol and place in a high-energy ball mill for 4-6 hours to obtain superfine suspension A. The above modified nano-TiO 2 The powder, 0.6 part of stearic acid, 1 part of zinc stearate, 0.3 part of antioxidant 1024 and 0.5 part of polyvinylpyrrolidone were sequentially...

Embodiment 2

[0028] The preparation step of superhydrophobic coating material comprises the following:

[0029] 14 parts nano-TiO 2 The powder was added to 5 times the amount of ethanol-water mixture with a volume ratio of 1:1, ultrasonically dispersed and then stirred for 2 hours, and the temperature was kept at 70°C. Add a small amount of triethylamine, then slowly add 2 parts of silane coupling agent ethanol solution dropwise, fully react for 2 hours under rapid stirring conditions, after the reaction is completed, age at room temperature, filter with suction, wash with ethanol, and dry at 80°C to obtain the modified Nano-TiO 2 powder.

[0030] Add 90 parts of polyurethane and 12 parts of terpene resin to 80 parts of ethanol and place in a high-energy ball mill for 4-6 hours to obtain ultrafine suspension A. The above modified nano-TiO 2 The powder, 0.9 parts of stearic acid, 1.5 parts of zinc stearate, 0.6 parts of antioxidant 1024 and 0.8 parts of polyvinylpyrrolidone were sequent...

Embodiment 3

[0033] The preparation step of superhydrophobic coating material comprises the following:

[0034] 18 parts nano-TiO 2 The powder was added to 5 times the amount of ethanol-water mixture with a volume ratio of 1:1, ultrasonically dispersed and then stirred for 2 hours, and the temperature was kept at 80°C. Add a small amount of triethylamine, then slowly add 2.5 parts of silane coupling agent ethanol solution dropwise, fully react for 3 hours under rapid stirring conditions, after the reaction is completed, age at room temperature, filter with suction, wash with ethanol, and dry at 80°C to obtain the improved Nano-TiO 2 powder.

[0035] 100 parts of polyurethane and 14 parts of terpene resin were added to 80 parts of ethanol and placed in a high-energy ball mill for 5 hours to obtain ultrafine suspension A. The above modified nano-TiO 2 The powder, 1.2 parts of stearic acid, 1.5 parts of zinc stearate, 0.8 parts of antioxidant 1024 and 1.0 part of polyvinylpyrrolidone were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com