Cotton-containing non-woven fabric with excellent flexibility and manufacturing method thereof

A manufacturing method and soft technology, applied in the manufacture of rayon, textiles and paper, non-woven fabrics, etc., can solve the problems of light resistance, heat resistance, cotton fabric damage, mold intolerance, etc., to improve strength, Improve light resistance and weather resistance, the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

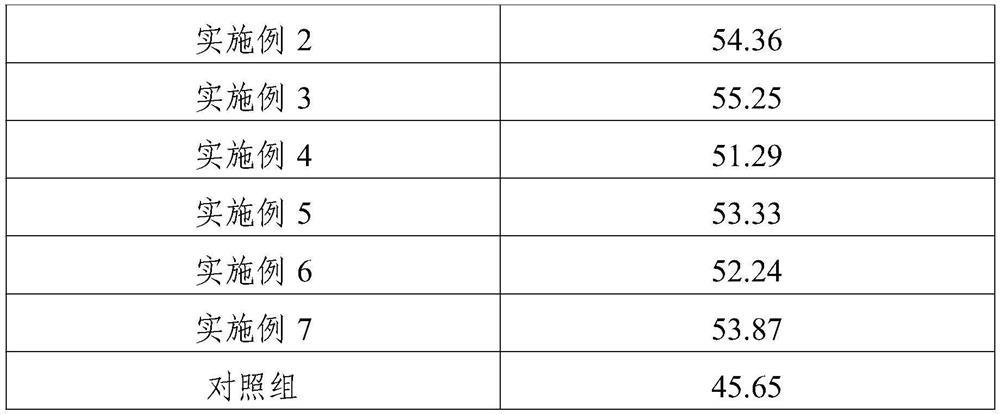

Embodiment 1

[0027] A cotton-containing non-woven fabric with excellent softness comprises the following raw materials in parts by weight: 60 parts of polypropylene, 20 parts of cotton fiber, 10 parts of softening agent, 6 parts of graphene, 5 parts of nano-titanium dioxide, and 20 parts of deionized water.

[0028] The diameter of cotton fiber is 15-20μm, the fiber length is 20-30mm, and the fineness is 5000-6500m / g; the softening agent includes polydimethylsiloxane and helium polysiloxane, and polydimethylsiloxane Alkane and helium polysiloxane are mixed in a mass ratio of 1:2; the particle size of graphene is 20-50nm.

[0029] The manufacturing method of the above-mentioned cotton-containing non-woven fabric with excellent softness specifically comprises the following steps:

[0030] (1) Cotton fibers are fed into a carding machine for carding, and then fed into a web-laying machine to lay a net after carding to obtain a cotton fiber web;

[0031] (2) Place deionized water, graphene an...

Embodiment 2

[0036] A cotton-containing nonwoven fabric with excellent softness comprises the following raw materials in parts by weight: 65 parts of polypropylene, 22 parts of cotton fiber, 12 parts of softening agent, 7 parts of graphene, 5 parts of nano-titanium dioxide, and 25 parts of deionized water.

[0037] The diameter of cotton fiber is 15-20μm, the fiber length is 20-30mm, and the fineness is 5000-6500m / g; the softening agent includes polydimethylsiloxane and helium polysiloxane, and polydimethylsiloxane Alkane and helium polysiloxane are mixed in a mass ratio of 1:2; the particle size of graphene is 20-50nm.

[0038] The manufacturing method of the above-mentioned cotton-containing non-woven fabric with excellent softness specifically comprises the following steps:

[0039] (1) Cotton fibers are fed into a carding machine for carding, and then fed into a web-laying machine to lay a net after carding to obtain a cotton fiber web;

[0040] (2) Place deionized water, graphene and...

Embodiment 3

[0045]A cotton-containing nonwoven fabric with excellent softness comprises the following raw materials in parts by weight: 70 parts of polypropylene, 27 parts of cotton fiber, 13 parts of softening agent, 8 parts of graphene, 7 parts of nano-titanium dioxide, and 19 parts of deionized water.

[0046] The diameter of cotton fiber is 15-20μm, the fiber length is 20-30mm, and the fineness is 5000-6500m / g; the softening agent includes polydimethylsiloxane and helium polysiloxane, and polydimethylsiloxane Alkane and helium polysiloxane are mixed in a mass ratio of 1:2; the particle size of graphene is 20-50nm.

[0047] The manufacturing method of the above-mentioned cotton-containing non-woven fabric with excellent softness specifically comprises the following steps:

[0048] (1) Cotton fibers are fed into a carding machine for carding, and then fed into a web-laying machine to lay a net after carding to obtain a cotton fiber web;

[0049] (2) Place deionized water, graphene and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com