Display backboard, manufacturing method thereof and display device

A manufacturing method and display backplane technology, applied in the display backplane and its manufacture, and in the field of display devices, can solve problems such as slow deposition, influence on coating effect, and change in solution viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

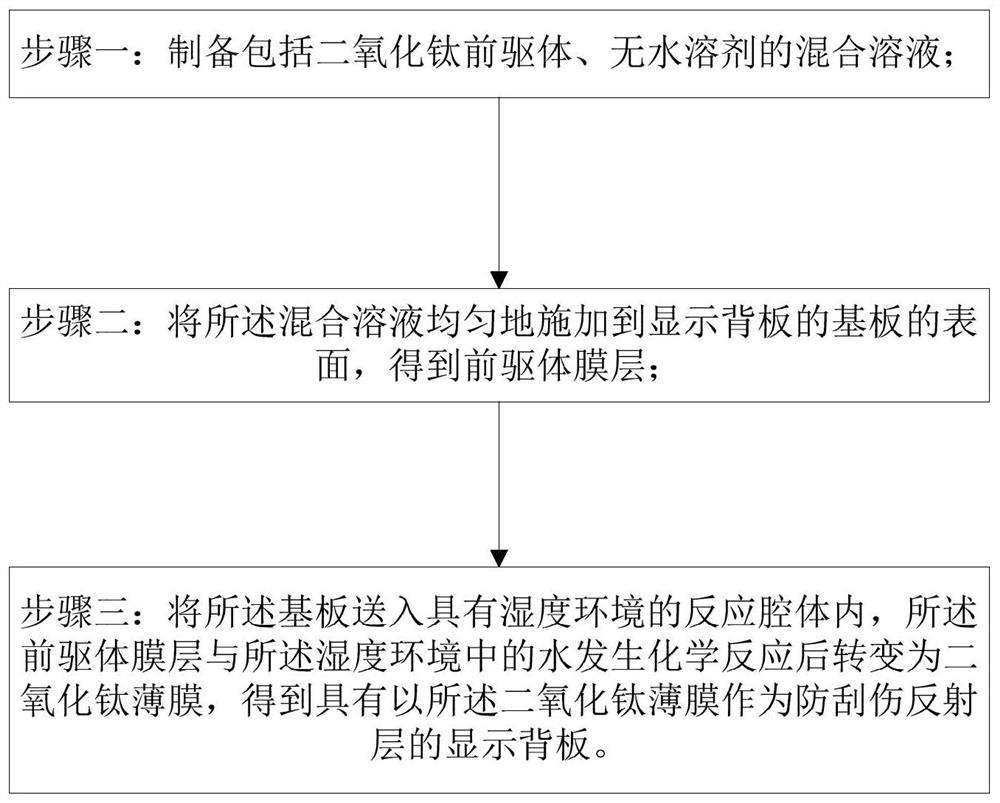

[0035] In this embodiment, the preparation of the mixed solution in the first step is to mix the main titanium dioxide precursor and other auxiliary substances in an anhydrous solvent in a photoresist barrel to obtain a uniform mixed solution.

[0036] The titanium dioxide precursor is a solution-type precursor prepared by a solution method. In this embodiment, titanium alkoxide is preferably used as the titanium dioxide precursor, such as titanium isopropoxide, titanium n-butoxide, and the like.

[0037] The anhydrous solvent used in this embodiment is an anhydrous alcohol solvent, which can ensure the stability of the titanium dioxide precursor. The mixed solution is a uniform and stable clear liquid, and will not precipitate due to standing, thereby affecting the coating. cloth effect.

[0038] The remaining auxiliary substances in this embodiment include one or more of dispersants, binders, coupling agents, and photosensitizers.

[0039] The method of applying the mixed s...

Embodiment 2

[0046] Embodiment 2 of the present invention also provides a display backplane and its manufacturing method, and a display device including the display backplane. The difference between the manufacturing method of this embodiment and the manufacturing method of Embodiment 1 above is that this embodiment Titanium oxysulfate is selected as the main titanium dioxide precursor in the medium mixed solution. Titanyl sulfate also has the ability to maintain stable performance in anhydrous solvents, and can undergo a chemical reaction to form titanium dioxide after encountering water. The rest of the method steps are basically the same as those in Embodiment 1 of the present invention, and will not be repeated in this embodiment.

Embodiment 3

[0048] Embodiment 3 of the present invention provides a display backplane and its manufacturing method, and a display device including the display backplane. The difference between the manufacturing method of this embodiment and the manufacturing method of Embodiment 1 above is that in this embodiment Titanium tetrachloride is selected as the main titanium dioxide precursor in the mixed solution. Titanium tetrachloride maintains stable performance in anhydrous solvents, and can undergo a chemical reaction to form titanium dioxide after encountering water. The rest of the method steps are basically the same as those in Embodiment 1 of the present invention, and will not be repeated in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com