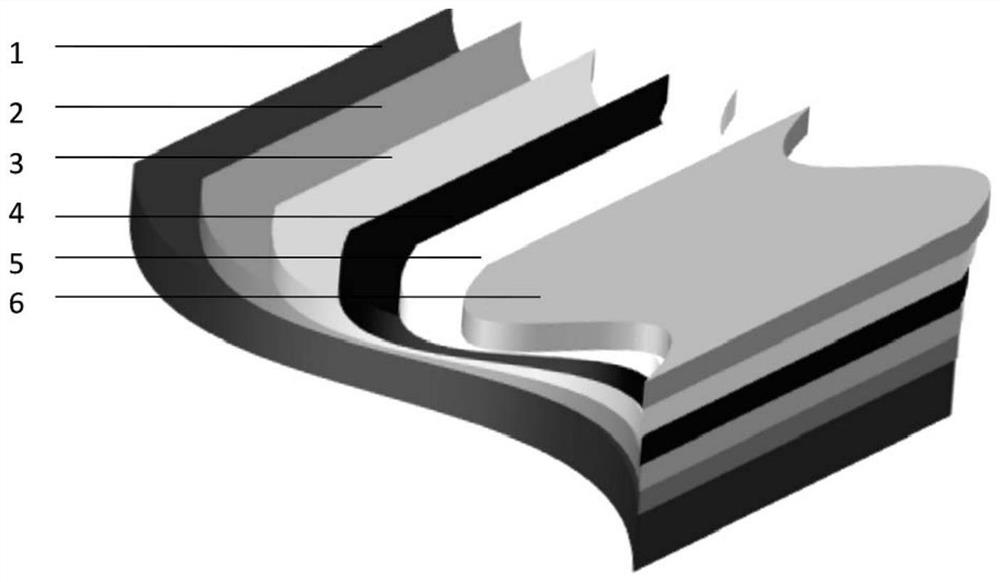

Double-electron-transport-layer flexible perovskite solar cell and preparation method thereof

A dual electron transport, solar cell technology, applied in the field of solar cells, can solve the problems of uneven thin film, holes, etc., and achieve the effects of simple preparation process, reduced leakage current, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

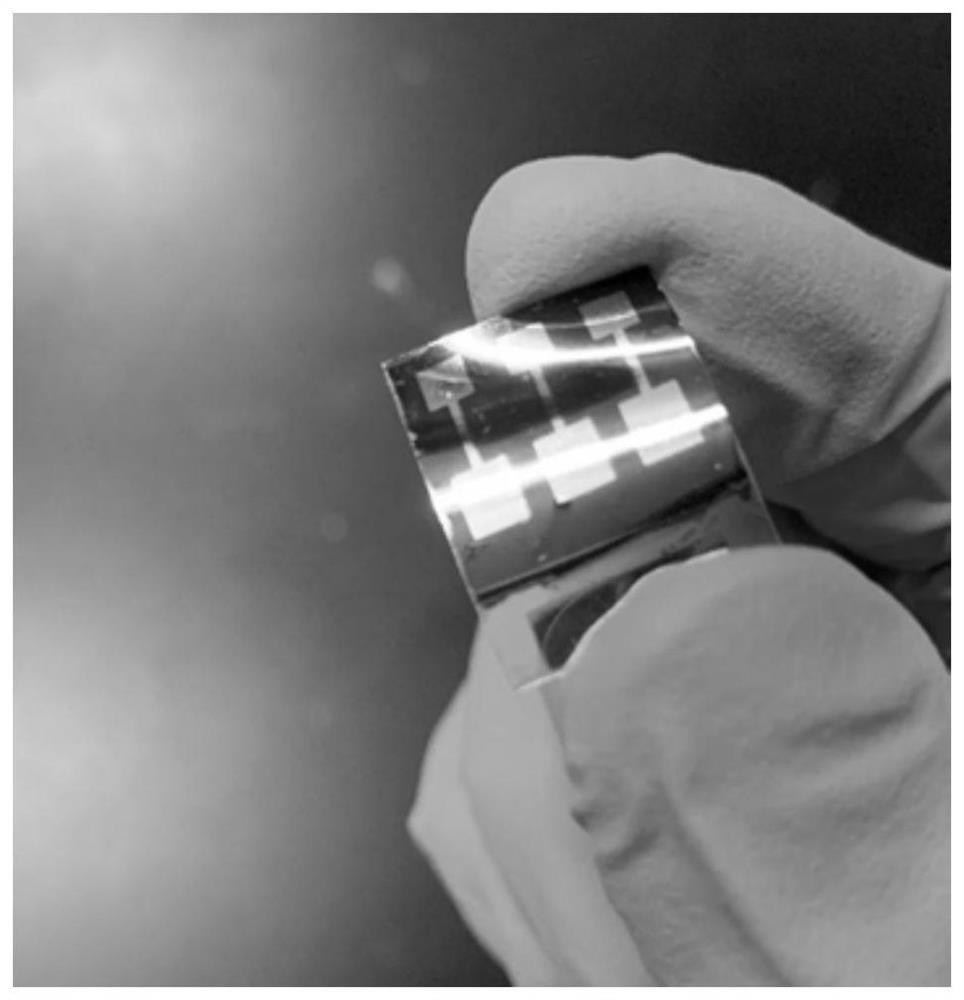

Method used

Image

Examples

Embodiment 1

[0037] 1. Cleaning of the conductive substrate: Cut the PET flexible substrate according to the required size, etch it with diluted hydrochloric acid and zinc powder, and then ultrasonically clean it with detergent, deionized water, acetone, ethanol, and isopropanol After cleaning for 15 minutes, dry the glass with a nitrogen gun, and then treat it with an ultraviolet ozone cleaning machine for 20 minutes, and set it aside;

[0038] 2. SnO 2 Preparation of the electron transport layer: the commercial SnO 2 The hydrosol and deionized water were mixed and diluted according to the volume ratio of 1:7, and then spin-coated on the cleaned flexible substrate at a speed of 3000 rpm for 30 s. After the spin coating is finished, place it on a heating table and heat it at 150°C for 30 minutes;

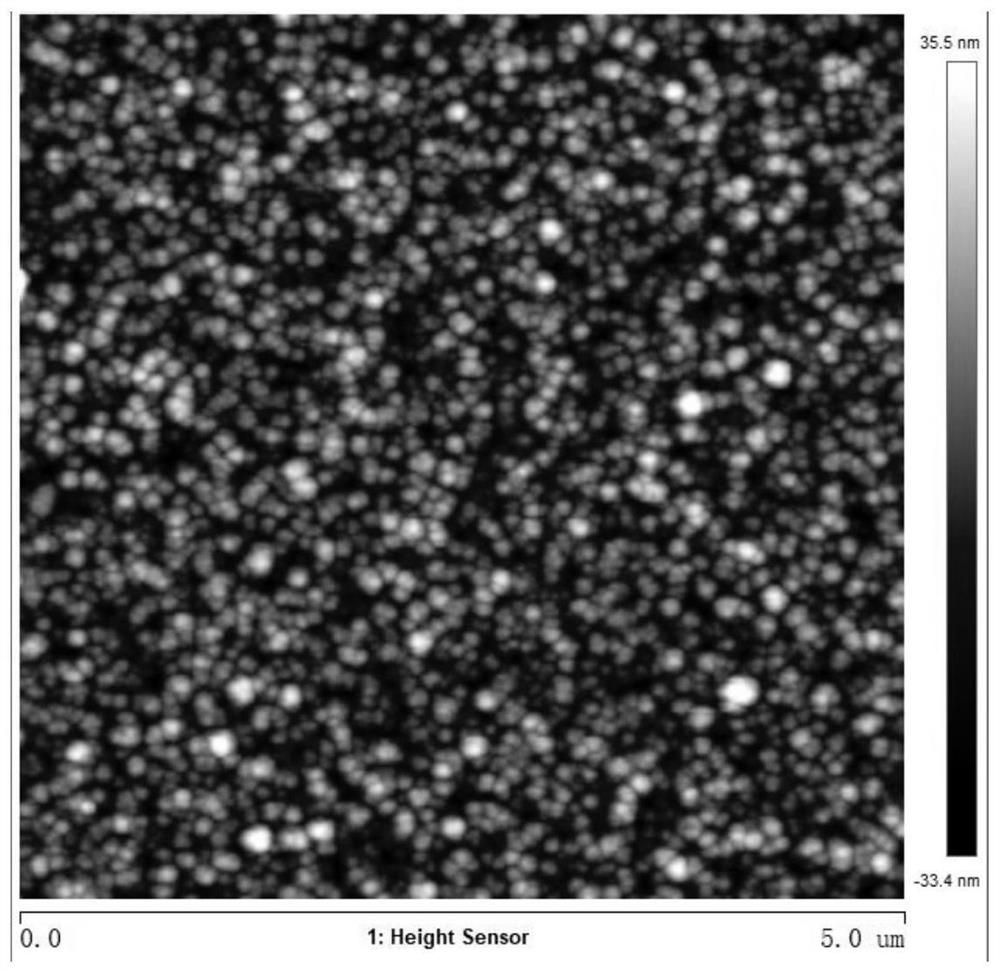

[0039] 3. Preparation of CdS electron transport layer: the flexible substrate prepared in step 2 / SnO 2 The film was put into a precursor solution composed of deionized water, cadmium acetate,...

Embodiment 2

[0047] 1. Cleaning of the conductive substrate: Cut the PET flexible substrate according to the required size, etch it with diluted hydrochloric acid and zinc powder, and then ultrasonically clean it with detergent, deionized water, acetone, ethanol, and isopropanol After cleaning for 15 minutes, dry the glass with a nitrogen gun, and then treat it with an ultraviolet ozone cleaning machine for 20 minutes, and set it aside;

[0048] 2. SnO 2 Preparation of the electron transport layer: the commercial SnO 2 The hydrosol was diluted with deionized water according to a certain volume ratio, and then spin-coated on the cleaned flexible substrate at a speed of 3000 rpm for 30 s. After the spin coating is finished, place it on a heating table and heat it at 150°C for 30 minutes;

[0049] 3. Preparation of CdS electron transport layer: the flexible substrate prepared in step 2 / SnO 2 The film was put into a precursor solution composed of deionized water, cadmium acetate, ammonium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com