A preparation method of adhesive for adhesive tape solder, adhesive tape solder and brazing method

A brazing method and binder technology are applied in the field of adhesive tape brazing filler metal and brazing, and the preparation field of adhesive tape brazing filler metal, which can solve the health hazards of production personnel, non-compliance with environmental protection requirements, and poor alloy uniformity. and other problems, to achieve the effect of ensuring full decomposition, good flexibility, and low carbon residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

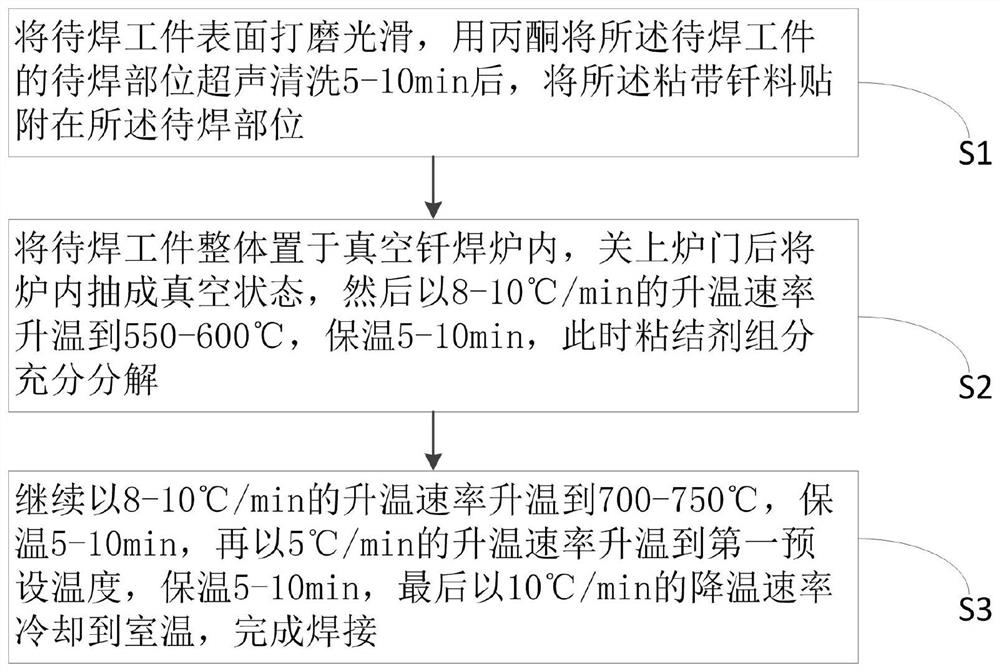

Method used

Image

Examples

preparation example Construction

[0025] An embodiment of the present invention provides a method for preparing an adhesive for adhesive tape solder, comprising: according to the weight ratio of each component, 30-70% of epoxy resin, 21-63% of plasticizer and 3 -21% of the toughening agent is placed in a stirrer and stirred at a speed of 30-60r / min for 5-15min to prepare the binder.

[0026] In the present embodiment, epoxy resin is used for bonding solder powder. In some preferred embodiments, the grade of epoxy resin is E44, and it is a bisphenol A type epoxy resin with strong adhesion and a thermal decomposition temperature T d The temperature is 385°C-413°C, and the amount of residual carbon after welding is low. And compared with the polymethyl methacrylate that mostly uses in the prior art, epoxy resin E44 is cheap, has cost advantage, and polymethyl methacrylate is solid under normal temperature, needs heating and complex process in the preparation process , while the epoxy resin E44 is liquid at room ...

Embodiment 1

[0045] An embodiment of the present invention provides a method for preparing a binder for adhesive tape solder, comprising:

[0046] Mix 40g terpene resin and 60g dibutyl phthalate evenly, seal the container and let it stand for 18h, transfer the mixture to a stirrer, and stir for 5min at a speed of 60r / min to make a plasticizer; Dibutyl phthalate can also be replaced by one or more of N-methylpyrrolidone, acetone or ethyl acetate, and its quality is configured according to the weight ratio of each component;

[0047] Mix 75g of ethyl cellulose and 25g of absolute ethanol evenly, seal the container and let it stand for 18 hours, then transfer the mixture to a stirrer, and stir for 5 minutes at a speed of 60r / min to make a toughening agent; wherein ethyl cellulose is also It can be replaced by one or more of styrene-based thermoplastic elastomer, acrylonitrile-butadiene-styrene terpolymer, butadiene rubber, and one or both of ethyl acetate and acetone can be used for absolute ...

Embodiment 2

[0053] An embodiment of the present invention provides a method for preparing a binder for adhesive tape solder, comprising:

[0054] Mix 20g of terpene resin with 15g of dibutyl phthalate and 15g of ethyl acetate evenly, seal the container and let it stand for 12h, transfer the mixture to a stirrer, and stir for 10min at a speed of 30r / min.

[0055] made into plasticizers;

[0056] Evenly mix 84g of styrene-based thermoplastic elastomer with 16g of ethyl acetate, seal the container and let it stand for 12h, transfer the mixture to a stirrer, and stir at a speed of 50r / min for 8min to make a toughening agent;

[0057] 45g epoxy resin E44, 44g plasticizer and 11g toughening agent are fully mixed to obtain adhesive;

[0058] Fully mix the solder particles with diameters of 5 μm, 10 μm, 30 μm, and 50 μm in the ratio of 8g: 34g: 35g: 23g to obtain solder powder;

[0059] Mix 12g of binder and 88g of solder powder evenly, place in a stirrer, and stir at a speed of 60r / min for 30m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com