Method for synthesizing high-performance dispersing agent from 3-methyl-2-nitrobenzoic acid wastewater

A nitrobenzoic acid, high-performance technology, applied in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve problems such as fluidity, adaptability and stability, low gas content, and poor workability. Achieve the effects of eliminating efflorescence, improving safety performance, and extending the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

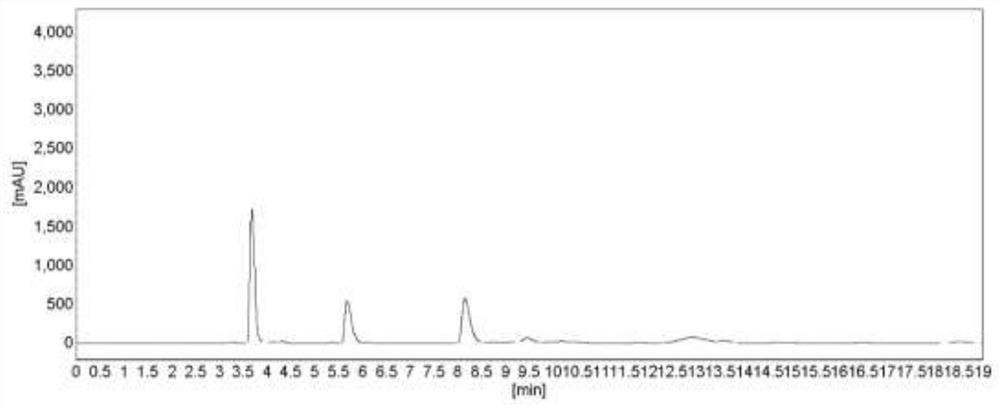

Image

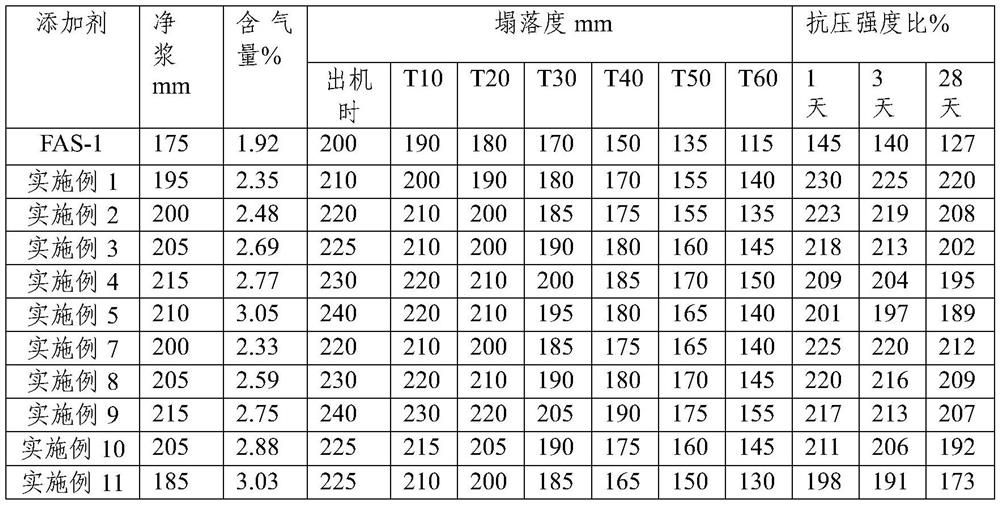

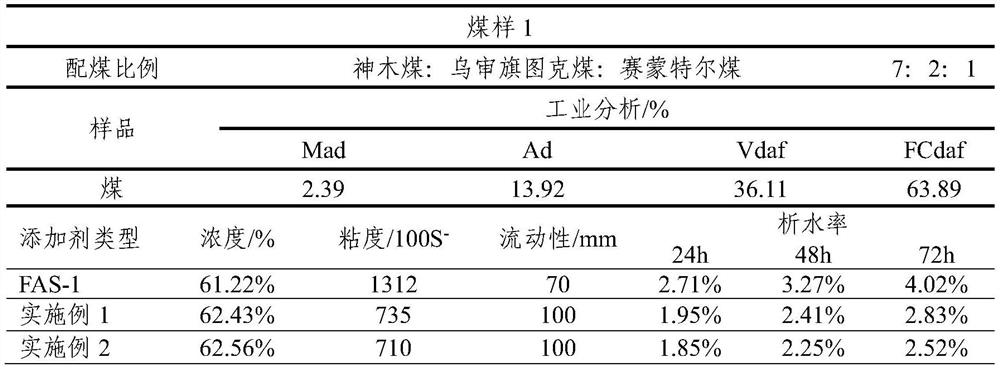

Examples

Embodiment 1

[0031] A method for synthesizing a high-performance dispersant from 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the steps:

[0032] Add 400 parts of 3-methyl-2-nitrobenzoic acid wastewater (solid content is 10wt%) in the reactor, add sulfonating agent, stir and mix evenly, add a certain amount of sodium hydroxide solution (32wt%) to adjust pH value to 8.5-9.5, add 10 parts of sodium lignosulfonate, stir and mix evenly, sulfonation and heat preservation for 30 minutes, sulfonation heat preservation temperature does not exceed 50 ° C; then add 100 parts of acetone dropwise, the temperature during the acetone addition process does not exceed 55 ° C , the dropping time is 30min; after the dropwise addition of acetone is completed, continue to drop 270 parts of formaldehyde (36wt%) slowly, and the dropwise adding time of formaldehyde is 3h, and the temperature during the dropping process does not exceed 95°C. ℃ condensation an...

Embodiment 2

[0035] A method for synthesizing a high-performance dispersant from 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the steps of:

[0036] Add 400 parts of 3-methyl-2-nitrobenzoic acid waste water (solid content is 10wt%) in reactor, add sulfonating agent, stir and mix evenly, add a certain amount of sodium hydroxide solution (32wt%) to adjust pH value to 8.5-9.5, add 10 parts of sodium lignosulfonate, stir and mix evenly, sulfonation and heat preservation for 30 minutes, sulfonation heat preservation temperature does not exceed 50 °C; then add 100 parts of acetone dropwise, the temperature during the acetone addition process does not exceed 55 °C , it is 25 minutes long when dropping; after the dropwise addition of acetone is completed, continue to drop 260 parts of formaldehyde (36wt%) slowly, the formaldehyde is added dropwise for 5 hours, and the temperature during the dropwise addition does not exceed 95°C. After the drop...

Embodiment 3

[0039] A method for synthesizing a high-performance dispersant from 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the steps of:

[0040] Add 400 parts of 3-methyl-2-nitrobenzoic acid waste water (solid content is 13wt%) in reactor, add sulfonating agent, stir and mix evenly, add a certain amount of sodium hydroxide solution (32wt%) to adjust pH value to 7-8, add 20 parts of sodium lignosulfonate, stir and mix evenly, sulfonation and heat preservation for 30 minutes, sulfonation heat preservation temperature does not exceed 50 ° C; then add 100 parts of acetone dropwise, the temperature during the acetone addition process does not exceed 55 ° C , the dropping time is 40min; after the dropwise addition of acetone is completed, continue to drop 270 parts of formaldehyde (36wt%) slowly, and the dropwise adding time of formaldehyde is 3h, and the temperature during the dropping process does not exceed 95°C. ℃ condensation and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com