Krill oil extraction method

An extraction method, krill oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of high purification technology requirements, complex extraction components, low phospholipid content, etc., to achieve good refining effect, Reasonable content of polar components, effect of high content of polar components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

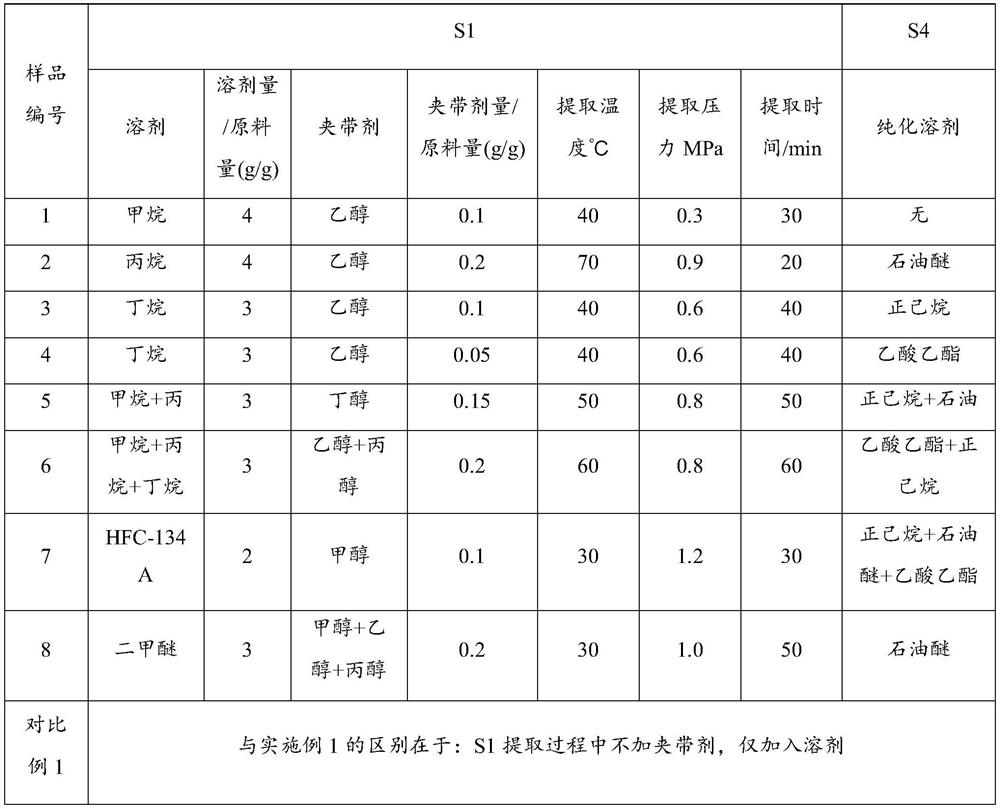

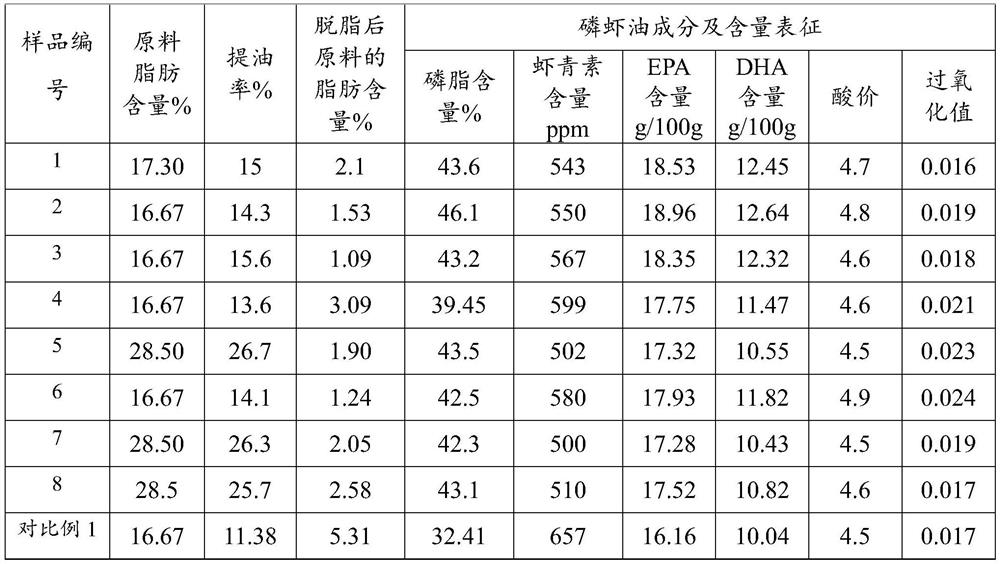

[0031] Example 1: Extraction method of krill oil:

[0032] S1: Take a certain amount of krill meal and put it in a 120-mesh nylon cloth bag, tie the mouth tightly, put it into the subcritical extraction kettle (tank), seal the tank mouth, and close all the exhaust valves, feed valves, and discharge valves of the equipment Wait, when the vacuum pump is turned on to vacuum -0.1MPa, the valve between the extraction kettle (tank) and the evaporation kettle (tank) is closed, and the vacuum pump is closed; open the solvent feed valve, and add a solvent 2-6 times the weight of the krill meal. When the solvent reaches half the amount of krill meal, close the solvent feed valve, add 5-20wt% entrainer by weight of krill meal through the entrainer feed device, close the entrainer feed valve, reopen the solvent feed valve, the solvent must be Drift over the shrimp meal (the total weight of solvent added is more than 2 times the weight of the krill meal). The extraction conditions are: ex...

Embodiment 2

[0058] Get the krill oil product of sample 3 in above-mentioned embodiment 1, utilize molecular distillation equipment to carry out the process of its secondary purification, the process of molecular distillation comprises:

[0059] (1) Close all valves of molecular distillation equipment, open vacuum pump, heater, cooling water, etc.

[0060] (2) When the system reaches a certain degree of vacuum (50-170pa) and the evaporator reaches a certain temperature (80-200℃), add the krill oil to the feeder.

[0061] (3) Open the feeding valve, adjust the feeding speed, and start distillation. When the vacuum degree rises to 120-130pa, 800g of oil is distilled for 30-60 minutes.

[0062] (4) When all the materials are processed, turn off the vacuum pump, heater, circulating water, and open the vent valve to the normal pressure state.

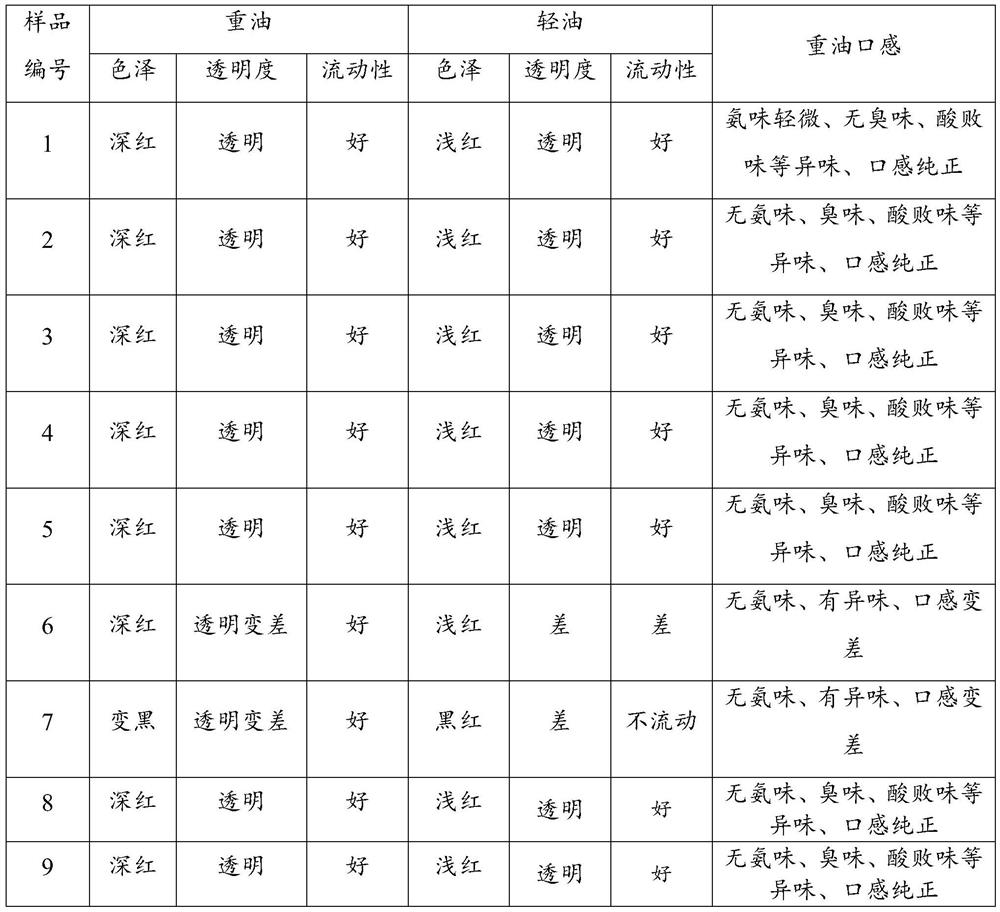

[0063] (5) Open the discharge valves of heavy molecule and light molecule collectors respectively to collect heavy molecule krill oil, light molecule o...

Embodiment 3

[0082] This embodiment continues the process of concentrating the krill oil after the secondary purification of sample 3 in Example 2, using the method of carbon dioxide supercritical distillation to concentrate the krill oil, and the concentration conditions are: the concentration temperature is 25~35 ℃ , the concentration pressure is 15~20Mpa; The temperature of separation still I is 35~45 ℃, and the pressure of separation still I is 8~10Mpa; The temperature of separation still II is 30~40 ℃, and the pressure of separation still II is 6~10Mpa; The concentration time is 2-6 hours. After the concentration, heavy oil, light oil and small molecular impurities are obtained respectively.

[0083] Specifically, the flow rate of carbon dioxide is controlled at 30-40 L / hour during the concentration process.

[0084] The specific implementation conditions are as follows:

[0085] The specific implementation conditions of table 7 embodiment 3

[0086]

[0087] Characterization: ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap