Brewing method of sea cucumber beer

A technology of sea cucumber and beer, which is applied in the direction of beer brewing, etc., can solve the problems affecting the taste of beer, and achieve the effect of mellow and unique taste, high alcohol content and attractive aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

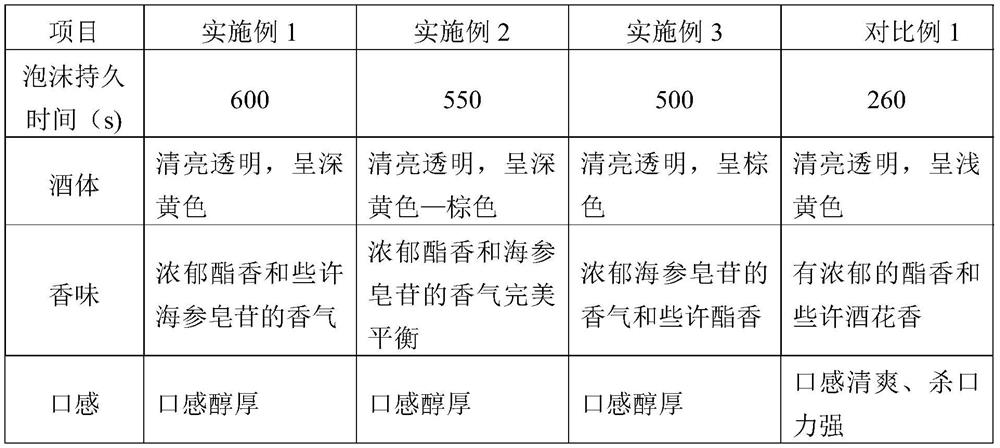

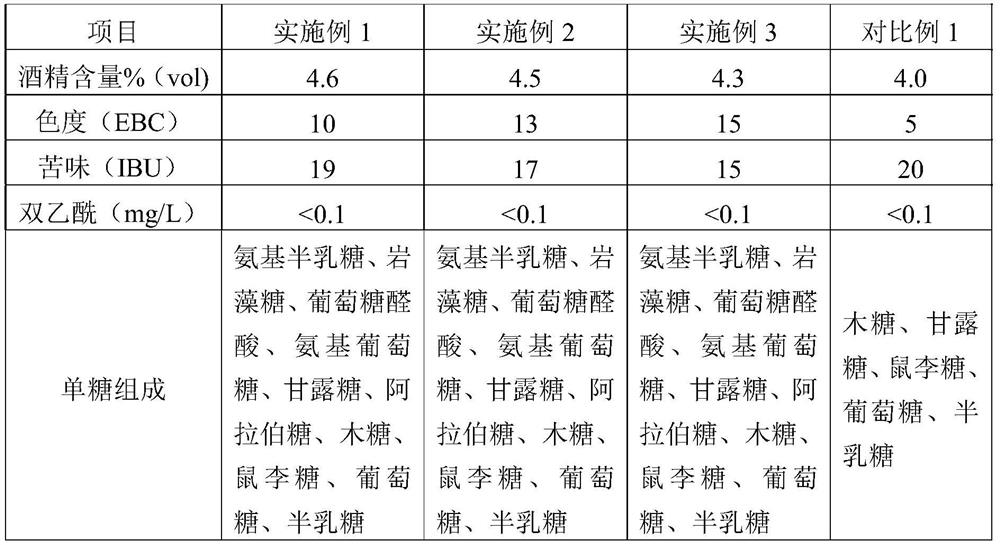

Examples

Embodiment 1

[0046] Sea cucumber beer ingredients: barley malt 110kg, wheat malt 50kg, total 160kg; fresh sea cucumber 30kg; hops 456g.

[0047] A brewing method of sea cucumber beer, comprising the steps of:

[0048]S1. Preparation of sea cucumber enzymatic hydrolyzate: fresh sea cucumber body wall is freeze-dried, pulverized, degreased, swollen, enzymolyzed, centrifuged, and freeze-dried to obtain sea cucumber enzymatic hydrolyzate. The specific steps are:

[0049] (1) Freeze-drying and pulverization: vacuum freeze-dry the body wall of the sea cucumber, the freezing temperature is -78°C, the pressure is 3-4Pa, the freezing time is 32h, and the sea cucumber powder is pulverized;

[0050] (2) Degreasing: Put the sea cucumber powder into the extraction tank, and pass through the supercritical CO 2 Extraction, extraction pressure is 35MPa; extraction temperature is 55°C; extraction time is 140min; CO 2 The flow rate is 15L / h, which removes lipids and fishy smell of sea cucumbers;

[0051]...

Embodiment 2

[0067] Sea cucumber beer ingredients: barley malt 100kg, wheat malt 40kg, crystalline malt 20kg, total 160kg; fresh sea cucumber 30kg; hops 456g.

[0068] A brewing method of sea cucumber beer, comprising the steps of:

[0069] S1. Preparation of sea cucumber enzymatic hydrolyzate: fresh sea cucumber body wall is freeze-dried, pulverized, degreased, swollen, enzymolyzed, centrifuged, and freeze-dried to obtain sea cucumber enzymatic hydrolyzate. The specific steps are:

[0070] (1) Freeze-drying and pulverization: vacuum freeze-dry the body wall of the sea cucumber, the freezing temperature is -78°C, the pressure is 3-4Pa, the freezing time is 32h, and the sea cucumber powder is pulverized;

[0071] (2) Degreasing: Put the sea cucumber powder into the extraction tank, and pass through the supercritical CO 2 Extraction, extraction pressure is 35MPa; extraction temperature is 55°C; extraction time is 140min; CO 2 The flow rate is 15L / h, which removes lipids and fishy smell of ...

Embodiment 3

[0088] Sea cucumber beer ingredients: barley malt 90kg, wheat malt 30kg, crystallized malt 20kg, caramel malt 20kg, total 160kg; fresh sea cucumber 30kg; hops 456g.

[0089] A brewing method of sea cucumber beer, comprising the steps of:

[0090] S1. Preparation of sea cucumber enzymatic hydrolyzate: fresh sea cucumber body wall is freeze-dried, pulverized, degreased, swollen, enzymolyzed, centrifuged, and freeze-dried to obtain sea cucumber enzymatic hydrolyzate. The specific steps are:

[0091] (1) Freeze-drying and pulverization: vacuum freeze-dry the body wall of the sea cucumber, the freezing temperature is -78°C, the pressure is 3-4Pa, the freezing time is 32h, and the sea cucumber powder is pulverized;

[0092] (2) Degreasing: Put the sea cucumber powder into the extraction tank, and pass through the supercritical CO 2 Extraction, extraction pressure is 35MPa; extraction temperature is 55°C; extraction time is 140min; CO 2 The flow rate is 15L / h, which removes lipids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com