Zn-doped MnFe2O4@C composite material for supercapacitor and preparation method of Zn-doped MnFe2O4@C composite material

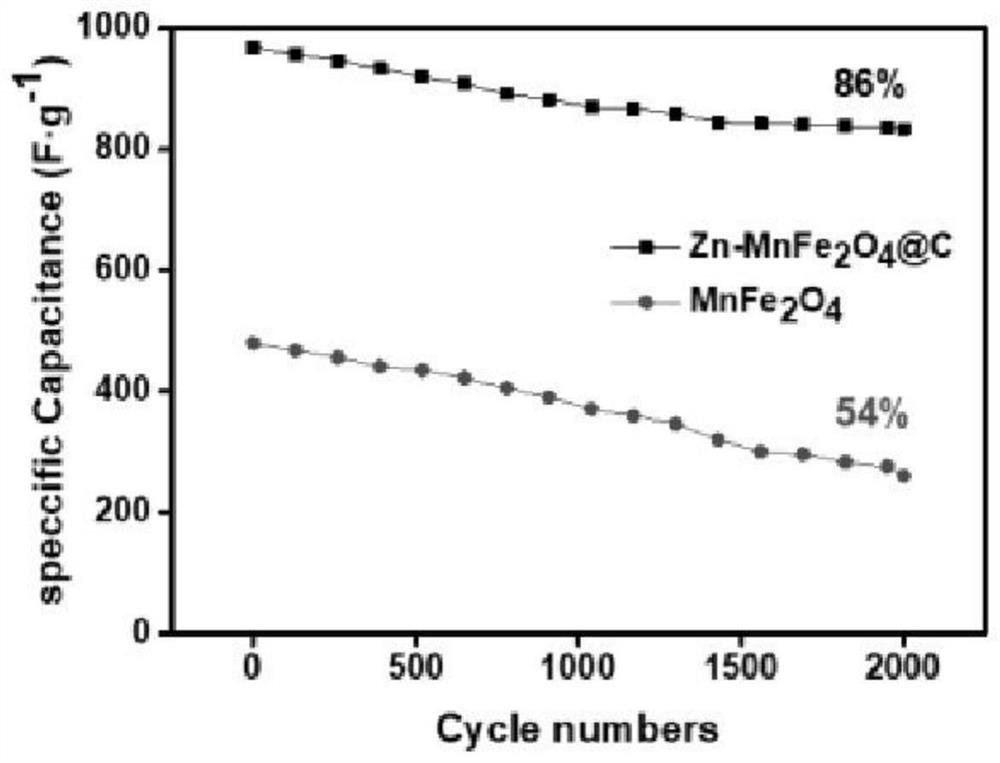

A composite material, mnfe2o4 technology, applied in the field of supercapacitor electrode material preparation, can solve the problems of low electrochemical activity, low conductivity, etc., to achieve the effect of increasing the contact area, improving the conductivity, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

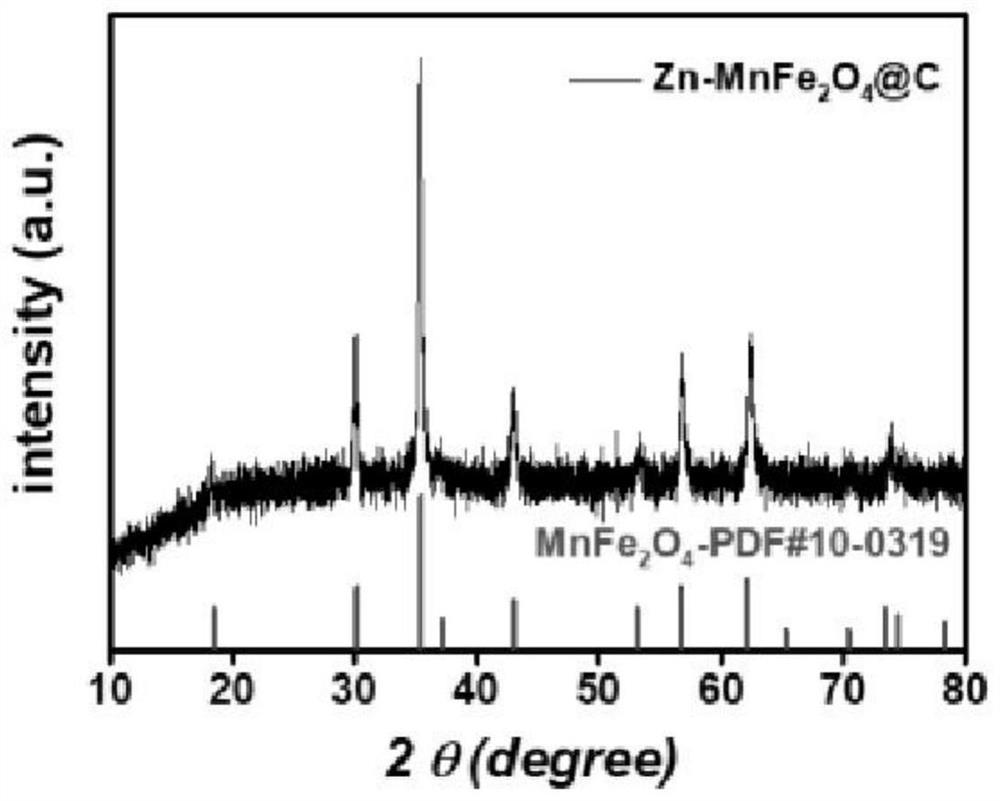

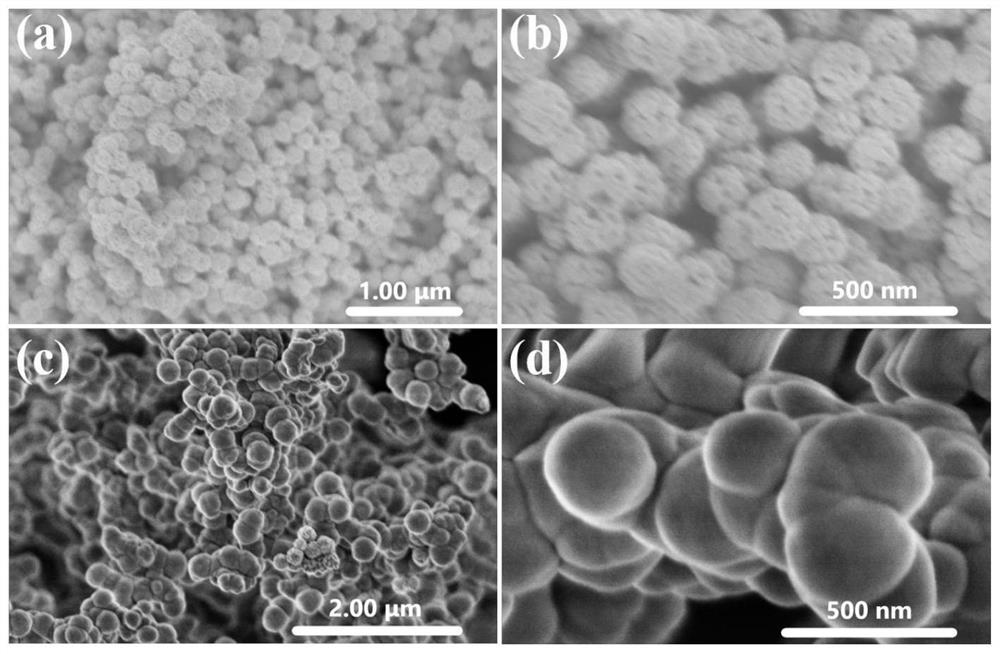

[0020] (1)MnFe 2 o 4 Preparation: Weigh 3.5mmol manganese chloride (MnCl 2 ), 7mmol ferric chloride (FeCl 3 ), 0.3gNH 4 F and 0.3 urea dissolved in 50mLH 2 O, then slowly add 0.1mol / L KOH solution to adjust the pH to 13, stir for 30 minutes, then move the mixture to a stainless steel autoclave with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 160°C for 12 hours, and wait to cool to room temperature The product was centrifuged and washed with deionized water, and dried in an oven at 70°C for 12 hours to obtain MnFe 2 o 4 .

[0021] (2) Zn-doped MnFe 2 o 4 The preparation: step (1) is made MnFe 2 o 4 and zinc nitrate (Zn(NO 3 ) 2 ) were fully mixed according to the mass ratio of 2:1, and then the mixture was annealed at 200°C for 2h under a hydrogen-argon mixed atmosphere.

[0022] (3) Zn-doped MnFe 2 o 4 The preparation of @PDA: the product that 120mg step (2) makes and 120mg dopamine hydrochloride (C 8 h 11 NO 2 HCl) was sequentially ad...

Embodiment 2

[0026] (1)MnFe 2 o 4 Preparation: Weigh 4mmol manganese chloride (MnCl 2 ), 8mmol ferric chloride (FeCl 3 ), 0.4gNH 4 F and 0.4g urea were dissolved in 50mLH 2 O, then slowly add 0.1mol / L KOH solution to adjust the pH to 13, stir for 30 minutes, then move the mixture to a stainless steel autoclave with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 170°C for 12 hours, and wait to cool to room temperature The product was centrifuged and washed with deionized water, and dried in an oven at 70°C for 12 hours to obtain MnFe 2 o 4 .

[0027] (2) Zn-doped MnFe 2 o 4 The preparation: step (1) is made MnFe 2 o 4 and zinc nitrate (Zn(NO 3 ) 2 ) were fully mixed according to the mass ratio of 2:1, and then the mixture was annealed at 250°C for 3h under a hydrogen-argon mixed atmosphere.

[0028] (3) Zn-doped MnFe 2 o 4 The preparation of @PDA: the product that 120mg step (2) makes and 120mg dopamine hydrochloride (C 8 h 11 NO 2 HCl) was sequentiall...

Embodiment 3

[0031] (1)MnFe 2 o 4 Preparation: Weigh 5mmol manganese chloride (MnCl 2 ), 10mmol ferric chloride (FeCl 3 ), 0.5gNH 4 F and 0.5g urea were dissolved in 50mLH 2 O, then slowly add 0.1mol / L KOH solution to adjust the pH to 13, stir for 30 minutes, then move the mixture to a stainless steel autoclave with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 170°C for 16 hours, and wait to cool to room temperature The product was centrifuged and washed with deionized water, and dried in an oven at 70°C for 12 hours to obtain MnFe 2 o 4 .

[0032] (2) Zn-doped MnFe 2 o 4 The preparation: step (1) is made MnFe 2 o 4 and zinc nitrate (Zn(NO 3 ) 2 ) were fully mixed according to the mass ratio of 2:1, and then the mixture was annealed at 270°C for 1.5h under a hydrogen-argon mixed atmosphere.

[0033] (3) Zn-doped MnFe 2 o 4 The preparation of @PDA: the product that 120mg step (2) makes and 120mg dopamine hydrochloride (C 8 h 11 NO 2 HCl) was sequenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com