Coating premix containing cyclodextrin and preparation method thereof

A technology for coating a premix and cyclodextrin, which is applied in the directions of medical preparations containing active ingredients, medical preparations without active ingredients, and pill delivery, etc., can solve the problems of cumbersome preparation methods, unfavorable administration for diabetics, and the like, Achieve the effects of good emulsion stability, low mold and Escherichia coli content, and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

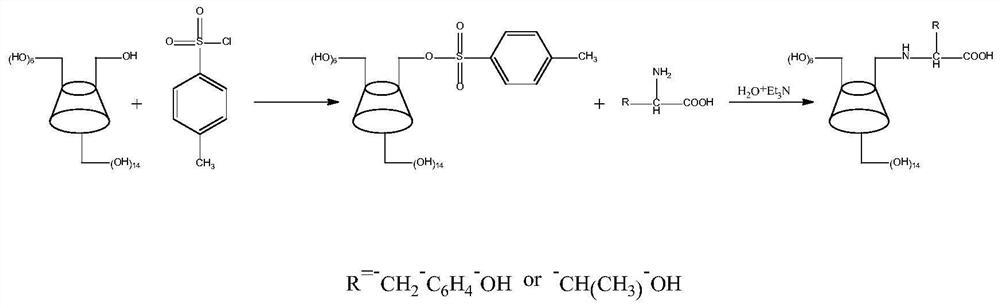

[0069] Embodiment 1: A kind of coating premix containing cyclodextrin:

[0070] This embodiment provides a coating premix containing cyclodextrin, which includes the following components and their weights:

[0071]

[0072]

[0073] Specifically, the coating premix containing cyclodextrin described in this example was prepared through the following steps:

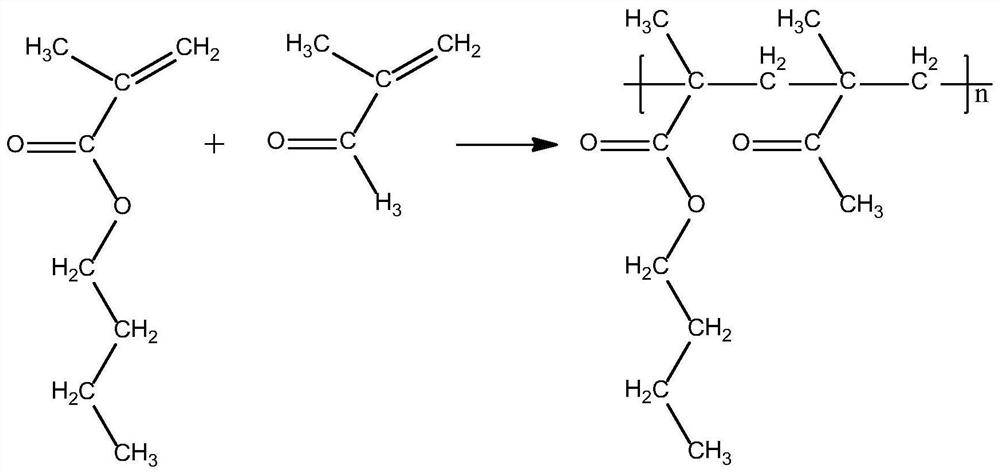

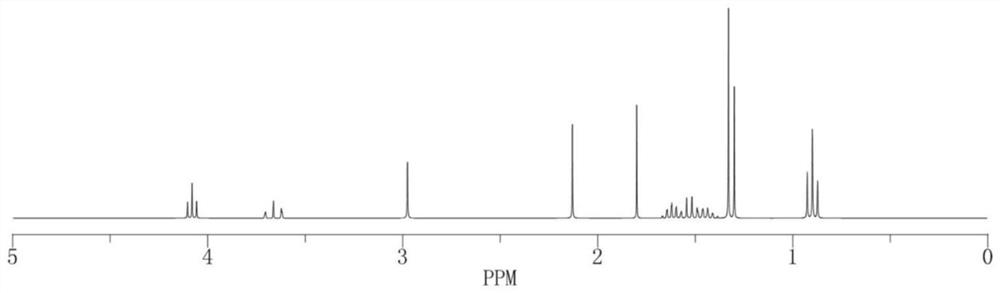

[0074] 1) Preparation of methyl methacrylate / butyl methacrylate copolymer emulsion:

[0075] 1.1) Mix 2.5g nonylphenol polyoxyethylene ether and 10.0g cetyltrimethylammonium bromide evenly, add 1000g deionized water and stir evenly to prepare a composite emulsifier system;

[0076] 1.2) 1mol methyl methacrylate and 1.5mol butyl methacrylate are mixed evenly and then slowly added to the compound emulsifier system in step 1) for pre-emulsification for 75min;

[0077] 1.3) To prepare a 2.0% potassium persulfate aqueous solution, first add 14 g of potassium persulfate aqueous solution to the system of step 1.2) at one...

Embodiment 2

[0088] Example 2: Another coating premix containing cyclodextrin:

[0089] This example provides another coating premix containing cyclodextrin, its components, proportions, and preparation methods are basically the same as in Example 1, the only difference is that the following composition and The polyacrylic resin obtained by the preparation method replaces the methyl methacrylate / butyl methacrylate copolymer emulsion and supplements the amount of water in the emulsion with deionized water:

[0090]100g of methacrylic acid, 20g of ethyl acrylate, 80g of butyl acrylate, 0.5g of potassium persulfate, 0.03g of nonoxynyl alcohol, 1.0g of sodium lauryl sulfate, 4.0g of polysorbate 80, 482g of purified water; its preparation The method steps are as follows: Weigh purified water, potassium persulfate, nonoxynyl polyol 10, sodium lauryl sulfate and polysorbate 80 into the reaction kettle, stir the reaction kettle at 120r / min, heat the reaction kettle within 20min to 90°C; weigh m...

Embodiment 3

[0091] Example 3: Another coating premix:

[0092] This example provides another coating premix, its components, proportions, and preparation methods are basically the same as in Example 2, the only difference is that neither tyrosine-modified cyclodextrin is added in this example No threonine-modified cyclodextrin was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com