Bone repair material and preparation method thereof

A technology for bone repair and material composition, applied in the field of medical biomaterials, can solve the problems of artificial joint loosening, high brittleness of CSC, inflammatory reaction, etc., and achieve the effect of avoiding excessive elastic modulus and quickly repairing bone defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Formula: 6MgO+ Ca(H 2 PO 4 ) 2 + 4NaH 2 PO 4 +Calcium deficiency HA (20%)

[0104] The preparation method of bone cement composite bone repair material comprises the following steps:

[0105] (1) Dissolve calcium-deficient hydroxyapatite particles into 200 μmol / L deferoxamine solution, stir for 2 hours, and then centrifuge and dry to obtain the required drug-loaded calcium-deficient hydroxyapatite particles;

[0106] (2) According to the above formula, uniformly mix magnesium oxide, calcium dihydrogen phosphate, sodium dihydrogen phosphate and calcium-deficient hydroxyapatite to obtain bone cement powder;

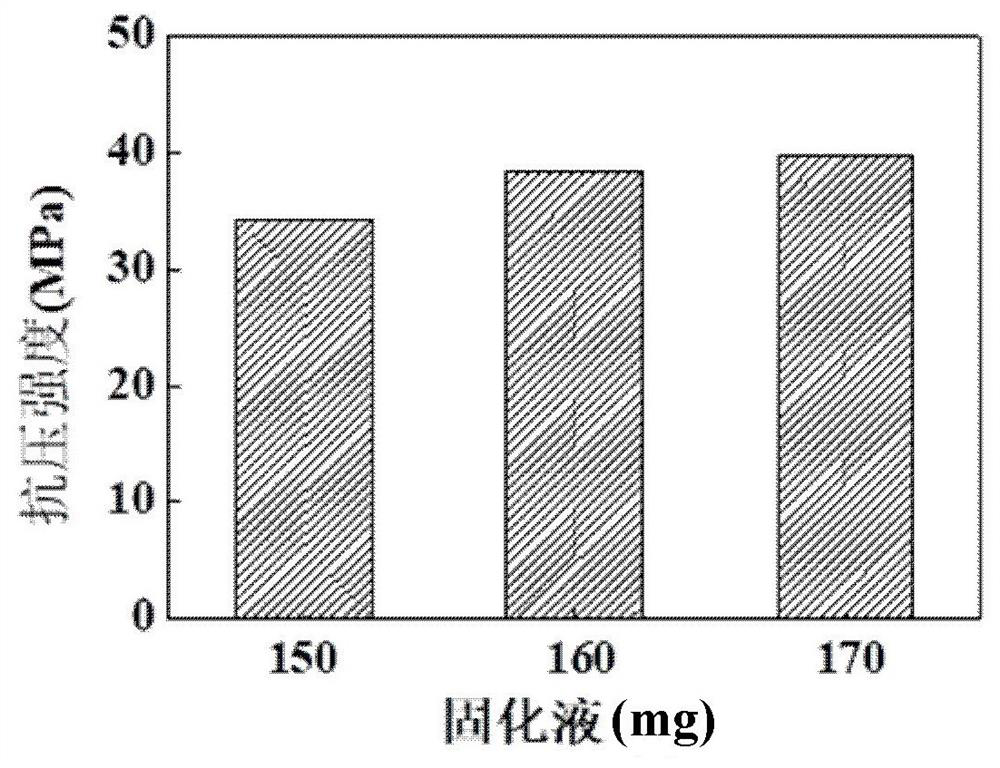

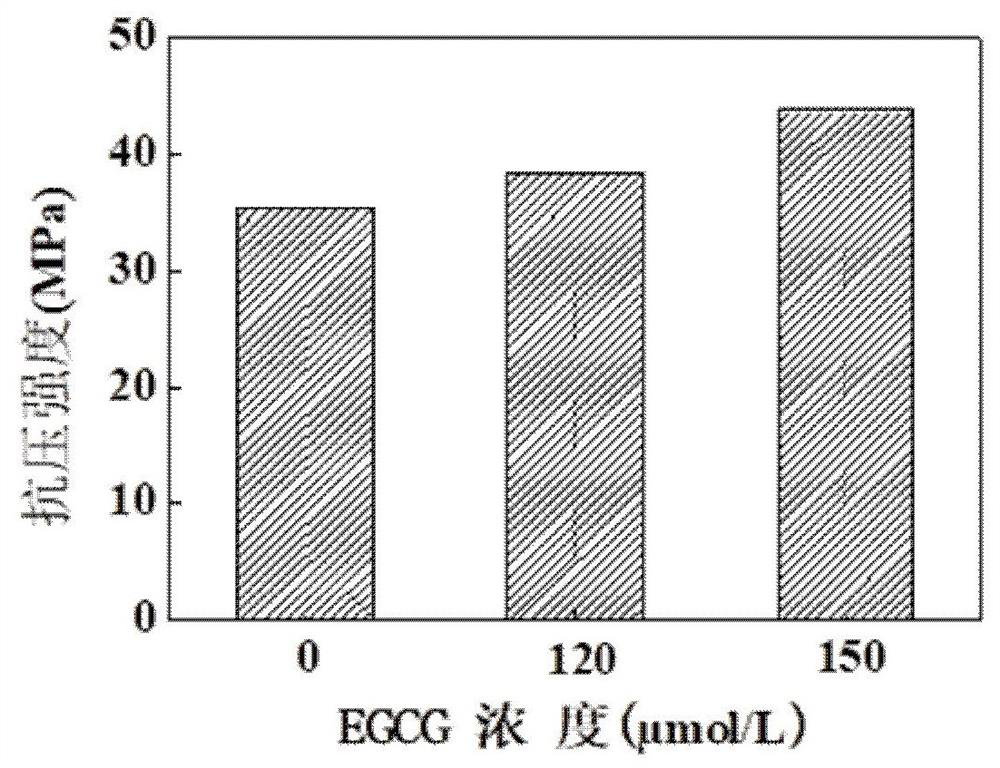

[0107] (3) Mix the bone cement powder and EGCG solidification solution (120 μmol / L) at a ratio of 0.55 g / 100 mg, and place them in a mold at 37°C and 100% humidity after solidification (setting time is 6-10 min). It can be cured for 72 h under ambient conditions.

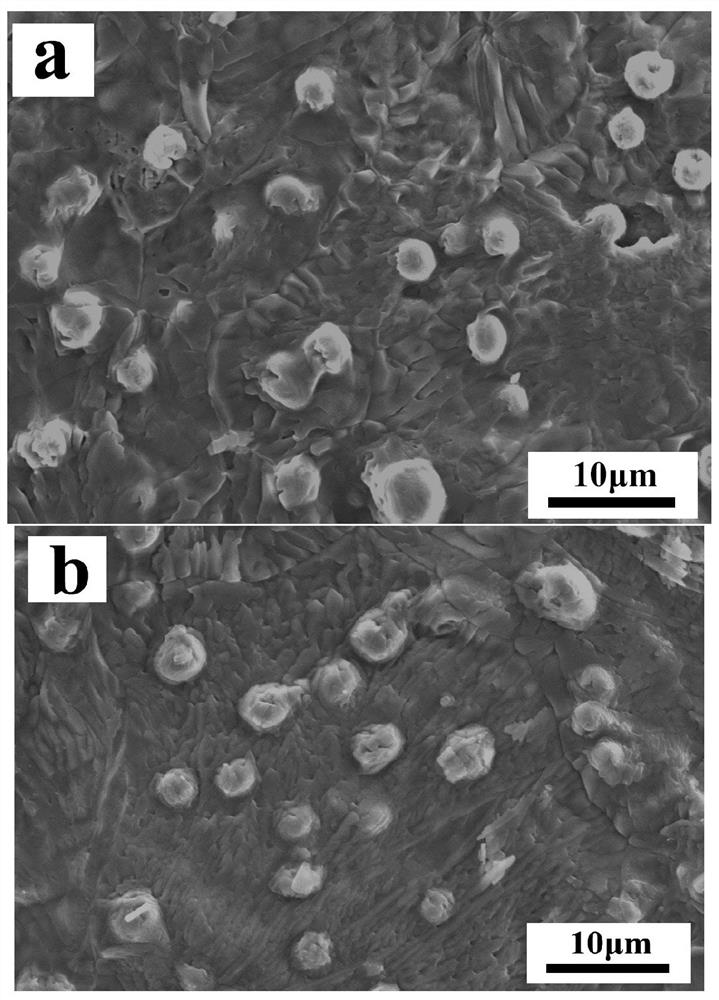

[0108] In bone cement composite bone repair materials, the particle size of calcium-deficient h...

Embodiment 2

[0110] Formula: 5MgO+ Ca(H 2 PO 4 ) 2 + 3NaH 2 PO 4 +Calcium deficiency HA (20%)

[0111] The preparation method of bone cement composite bone repair material comprises the following steps:

[0112] (1) Dissolve calcium-deficient hydroxyapatite particles into 200 μmol / L deferoxamine solution, stir for 2 hours, and then centrifuge and dry to obtain the required drug-loaded calcium-deficient hydroxyapatite particles;

[0113] (2) According to the above formula, uniformly mix magnesium oxide, calcium dihydrogen phosphate, sodium dihydrogen phosphate and calcium-deficient hydroxyapatite to obtain bone cement powder;

[0114] (3) Mix bone cement powder and EGCG solidification solution (120 μmol / L) at a ratio of 0.55 g / 120 mg, and place them in an environment of 37°C and 100% humidity after solidification in the mold (setting time is 6-10 minutes). It can be cured for 72 h.

[0115] In bone cement composite bone repair materials, the particle size of calcium-deficient hydroxya...

Embodiment 3

[0117] Formula: 3MgO+ Ca(H 2 PO4) 2 + NaH 2 PO 4 + Calcium-deficient HA (0%, 10% or 20%)

[0118] The preparation method of bone cement composite bone repair material comprises the following steps:

[0119] (1) According to the above formula, uniformly mix magnesium oxide, calcium dihydrogen phosphate, sodium dihydrogen phosphate and calcium-deficient hydroxyapatite to obtain bone cement powder;

[0120] (2) Evenly mix deferoxamine powder and bone cement powder;

[0121] (3) Mix deferoxamine-containing bone cement powder with EGCG solidification solution (120 μmol / L) at a ratio of 0.55 g / 150 mg, and put it in the mold at 37°C after solidification (setting time is 6-10 min). It can be cured for 72 h under the environment of 100% humidity.

[0122] In bone cement composite bone repair materials, the particle size of calcium-deficient hydroxyapatite is 3-5 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com