Microwave absorbing material and preparation method thereof

A microwave absorbing material and molecular formula technology, applied in the field of materials, can solve problems such as increasing production costs and coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the microwave absorbing material described in the above technical solution, comprising the following steps:

[0029] (1) metal nitrate is mixed with citric acid solution, and gelation reaction is carried out to obtain a gel; the metal nitrate includes bismuth nitrate, lanthanum nitrate and ferric nitrate or lanthanum nitrate and ferric nitrate;

[0030] (2) Drying, ashing and calcining the gel obtained in the step (1) in sequence to obtain a microwave absorbing material.

[0031] In the present invention, metal nitrate is mixed with citric acid solution for gelation reaction to obtain gel; the metal nitrate includes three kinds of bismuth nitrate, lanthanum nitrate and iron nitrate, or two kinds of lanthanum nitrate and iron nitrate. In the present invention, the bismuth nitrate is preferably bismuth nitrate pentahydrate; the lanthanum nitrate is preferably lanthanum nitrate hexahydrate, and the iron nitrate is...

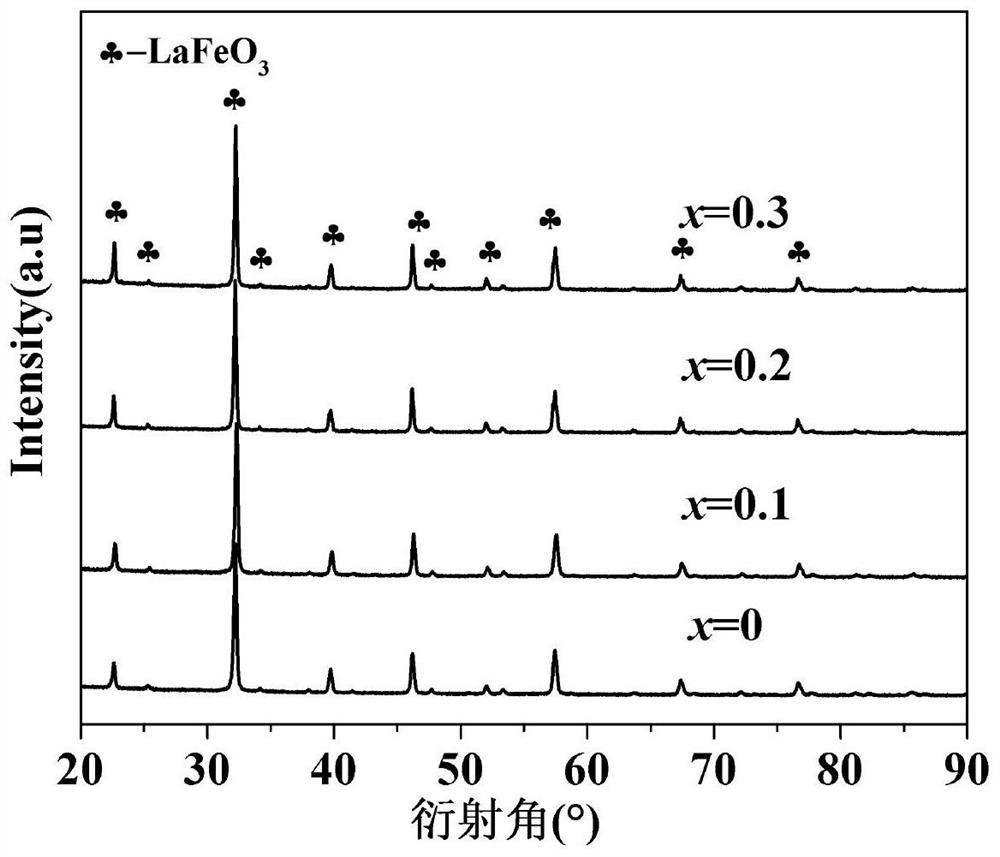

Embodiment 1

[0042] Step (1), according to molecular formula LaFeO 3 Take by weighing lanthanum nitrate hexahydrate 5.35g and ferric nitrate nonahydrate 4.99g (ratio of the amount of substance of lanthanum nitrate hexahydrate and ferric nitrate nonahydrate is 1:1) of purity >=99.9%, then according to metal ion (lanthanum ion and Iron ion) and citric acid mol ratio are 1: 1 and take by weighing citric acid 5.21g, citric acid and distilled water are mixed to obtain citric acid solution (the mass concentration of described citric acid solution is 16.1%), then lanthanum nitrate and ferric nitrate Add it to the citric acid solution and mix it, put the obtained solution into a water bath, and keep constant temperature magnetic stirring at 80°C (stirring speed is 250r / min), and carry out gelation reaction for 3 hours to obtain a gel;

[0043] Step (2), put the gel obtained in step (1) into a blast drying oven and dry at 80°C for 20 hours, and then put the dried product into a muffle furnace after...

Embodiment 2

[0045] Step (1), Bi 0.1 La 0.9 FeO 3 Take by weighing 0.72g of bismuth nitrate pentahydrate, 4.81g of lanthanum nitrate hexahydrate and 4.99g of iron nitrate nonahydrate (the ratio of the amount of substances of bismuth nitrate pentahydrate, lanthanum nitrate hexahydrate and iron nitrate nonahydrate is 0.1 : 0.9: 1), then according to metal ion (lanthanum ion, iron ion and barium ion) and citric acid molar ratio is 1:1 to take by weighing citric acid 5.19g, citric acid and distilled water are mixed and magnetically stirred to obtain citric acid solution ( The mass concentration of described citric acid solution is 16%), then bismuth nitrate, lanthanum nitrate and ferric nitrate are joined in the citric acid solution, gained solution is put into water bath, under 80 ℃ of conditions, continuous constant temperature magnetic stirring (stirring Speed is 250r / min), carry out gelation reaction 3.5h, obtain gel;

[0046] Step (2), put the gel obtained in step (1) into a blast dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com