Preparation method of gold-iron oxyhydroxide-cuprous oxide-copper sulfide composite paper

A technology of ferric oxyhydroxide and cuprous oxide, which is applied in liquid chemical plating, metal material coating process, electrodes, etc., can solve the problems of limiting hydrogen production performance, fast carrier recombination rate, poor light stability, etc. Achieve the effect of increasing the photocatalytic hydrogen production efficiency, abundant sources, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

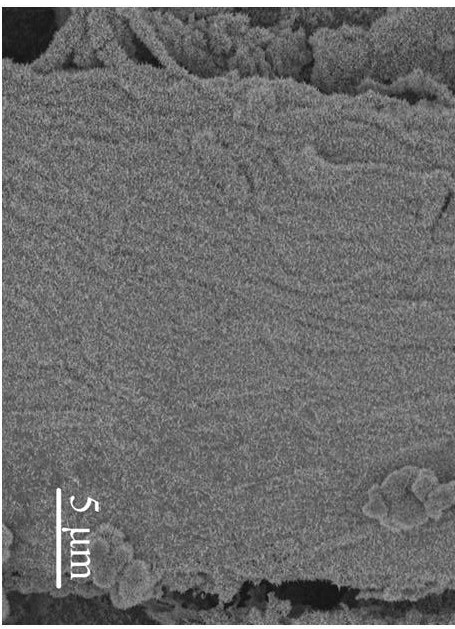

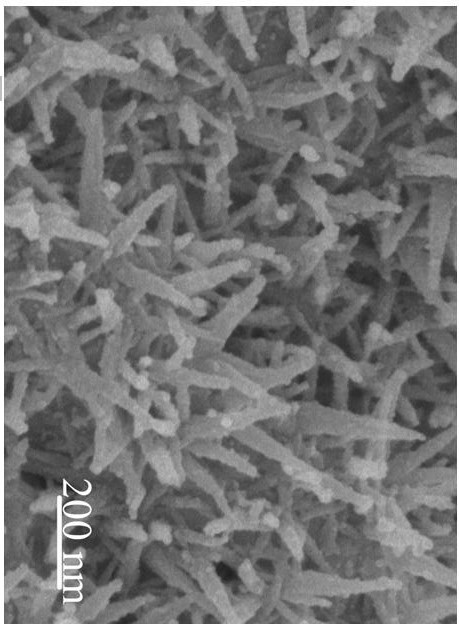

Image

Examples

Embodiment 1

[0017] The preparation method of gold-iron oxyhydroxide-cuprous oxide-copper sulfide composite paper, the specific preparation scheme is as follows:

[0018] (1) First use the computer software Adobe illustrator CS4 to design the paper chip batik pattern, and then use the wax printer to print the designed batik pattern on the chromatographic paper. The wax printer model used is Color Qube 8580, and then the printed chromatographic paper is placed Heated in an oven at 120 °C for 50 s to obtain the hydrophilic and hydrophobic regions of the paper chip;

[0019] (2) Preparation of gold paper electrode, the process is divided into 2 steps, the first step is to synthesize gold seed solution, first add 130 μL of 20 mM chloroauric acid solution to 6 mL of 120 mM hexadecyltri methyl ammonium bromide solution, and stirred at room temperature for 20 min, then added 0.3 mL of 10 mM sodium borohydride solution, the sodium borohydride solution used was ice-bathed for 40 min in advance, and...

Embodiment 2

[0022] The preparation steps were the same as in Example 1, except that in the second step of step (2), a layer of gold nanoparticles was grown on the hydrophilic region of the paper chip, and the reaction time used was 40 min.

Embodiment 3

[0024] The preparation steps are the same as in Example 1, except that the deposition time for the first step in step (3) is 20 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com