Etchant

一种蚀刻液、膦酸的技术,应用在表面浸蚀组合物、电气元件、电固体器件等方向,能够解决IGZO腐蚀、不能达成IGZO防蚀性、加工性等问题,达到防止IGZO腐蚀、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] [Preparation method of etching solution]

[0055] The etching solution of the present invention passes through HEDP (A), phosphonic acid (B), hydrogen peroxide (C), nitric acid (D), fluorine compound (E), azole (F), alkali (G) and other as required It is prepared by adding water (preferably ultrapure water) to the ingredients and stirring until they become uniform.

[0056] The pH range of the composition liquid is not particularly limited, but is usually 1.5 to 2.8, preferably 1.8 to 2.5. By being within this range, it is possible to appropriately prevent corrosion of IGZO and to etch the wiring material.

[0057] [How to use etchant]

[0058] The object can be etched by bringing the etchant of the present invention into contact with the object.

[0059] The method of bringing the etching solution of the present invention into contact with the object is not particularly limited. For example, a method of contacting the object with the etching liquid of the present in...

Embodiment

[0066] Hereinafter, although an Example demonstrates this invention more concretely, Embodiment can be changed suitably within the range which exhibits the effect of this invention.

[0067] In addition, unless otherwise specified, % means mass %.

[0068] [Substrate for evaluation]

[0069]

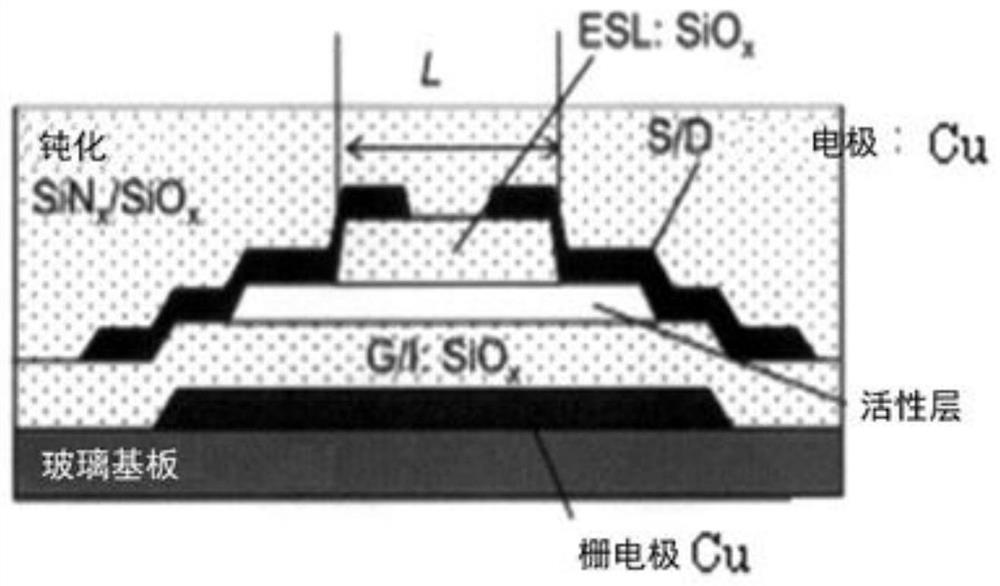

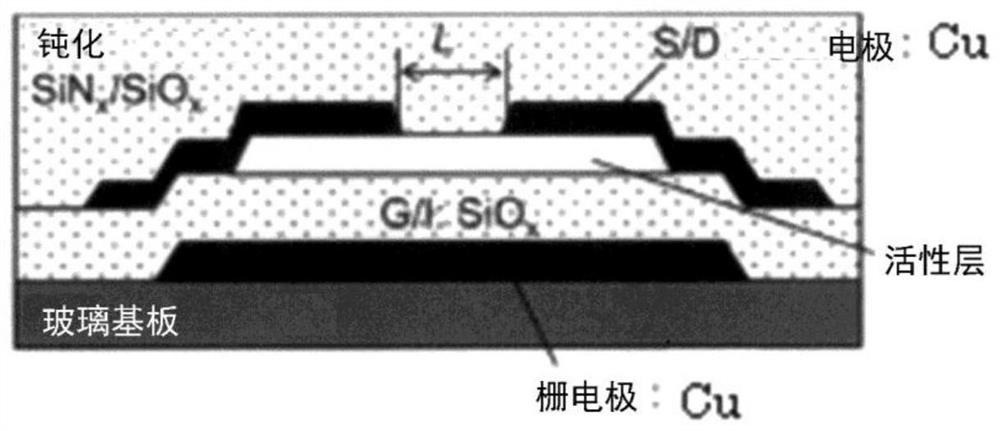

[0070] film thickness by sputtering (100nm) IGZO (100mm×100mm×1mm) with an elemental ratio of indium (In), gallium (Ga), zinc (Zn) and oxygen (O) of 1:1:1:4 was formed on a glass substrate.

[0071]

[0072] Titanium was sputtered to a thickness of 25 nm on a glass substrate to form a titanium layer, then copper was sputtered to a thickness of 600 nm, and a copper layer of a wiring material was laminated. Next, a resist is applied, a pattern mask is exposed and transferred, and then developed to form a wiring pattern, and a multilayer film (100mm×100mm×1mm) including a copper layer and a titanium layer is produced on a glass substrate.

[0073] [Evaluation method]

[0074] [Etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com