Preparation method and application of platinum-carbon quantum dot/multi-walled carbon nanotube composite material

A technology of multi-walled carbon nanotubes and carbon quantum dots, which is applied in the field of electrocatalytic materials, can solve problems such as complex, time-consuming preparation process, and limit the application of composite materials, and achieve the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

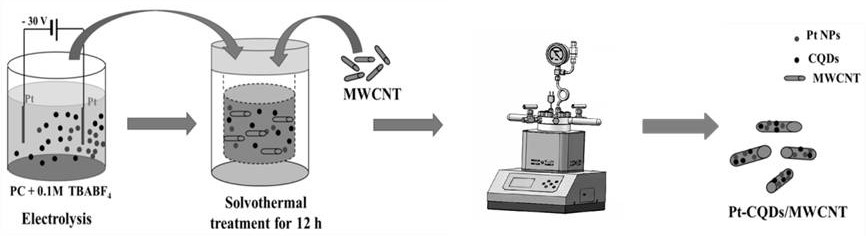

[0062] The specific preparation steps of 1#Pt-CQDs / NWCNT composites are as follows:

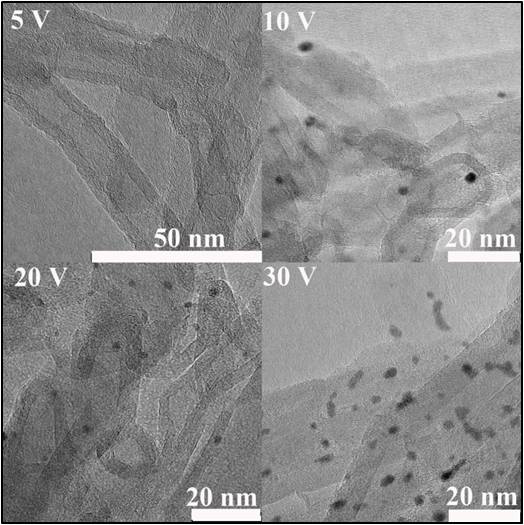

[0063] (1) Two platinum wire electrodes were immersed in propylene carbonate (PC) solution together with tetrabutylammonium tetrafluoroborate (0.1M) and a voltage of 30V was applied for 12h.

[0064] (2) 30 mg of multi-walled carbon nanotubes (MWCNTs) were put into the electrolyte solution in (1) above and stirred for 12 hours.

[0065] (3) Transfer the solution obtained in step (2) to a polytetrafluoroethylene cup with a volume of 80mL, then put the polytetrafluoroethylene cup into a stainless steel autoclave, seal the autoclave, and ventilate the autoclave Pass the flow of Ar into the autoclave for 0.5 hours, remove the air in the solution, and close the vent after removing the air;

[0066] (4) Place the above-mentioned airtight autoclave at 160° C. and react by solvothermal process for 12 hours;

[0067] (5) Filter the sample treated in (4), and use propylene carbonate (PC) solution suc...

Embodiment 2

[0071] The specific preparation steps of 2#Pt-CQDs / NWCNT composites are as follows:

[0072] (1) Dip two platinum wire electrodes into the propylene carbonate (PC) solution together with tetrabutylammonium tetrafluoroborate (0.1M) and apply a voltage of 20V for 12h;

[0073] (2) putting 30mg of multi-walled carbon nanotubes (MWCNT) into the electrolyte solution in the above (1) and stirring for 12 hours;

[0074] (3) Transfer the solution obtained in step (2) to a polytetrafluoroethylene cup with a volume of 80mL, then put the polytetrafluoroethylene cup into a stainless steel autoclave, seal the autoclave, and ventilate the autoclave Pass the flow of Ar into the autoclave for 0.5 hours, remove the air in the solution, and close the vent after removing the air;

[0075] (4) Place the above-mentioned airtight autoclave at 160° C. and react by solvothermal process for 12 hours;

[0076](4) Solvothermal process was adopted to process the solution for 12 hours at a speed of 500 ...

Embodiment 3

[0081] The specific preparation steps of 3#Pt-CQDs / NWCNT composites are as follows:

[0082] (1) Dip two platinum wire electrodes into the propylene carbonate (PC) solution together with tetrabutylammonium tetrafluoroborate (0.1M) and apply a voltage of 10V for 12h;

[0083] (2) putting 30mg of multi-walled carbon nanotubes (MWCNT) into the electrolyte solution in the above (1) and stirring for 12 hours;

[0084] (3) Transfer the solution obtained in step (2) to a polytetrafluoroethylene cup with a volume of 80mL, then put the polytetrafluoroethylene cup into a stainless steel autoclave, seal the autoclave, and ventilate the autoclave Pass the flow of Ar into the autoclave for 0.5 hours, remove the air in the solution, and close the vent after removing the air;

[0085] (4) Place the above-mentioned airtight autoclave at 160° C. and react by solvothermal process for 12 hours;

[0086] (5) Filter the sample treated in step (4), and use propylene carbonate (PC) solution for su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com