Preparation method of sulfide solid electrolyte

A solid electrolyte and sulfide technology, applied in the field of lithium-ion batteries, can solve the problems of poor air stability and achieve moderate crystallinity, good water resistance and oxidation resistance, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

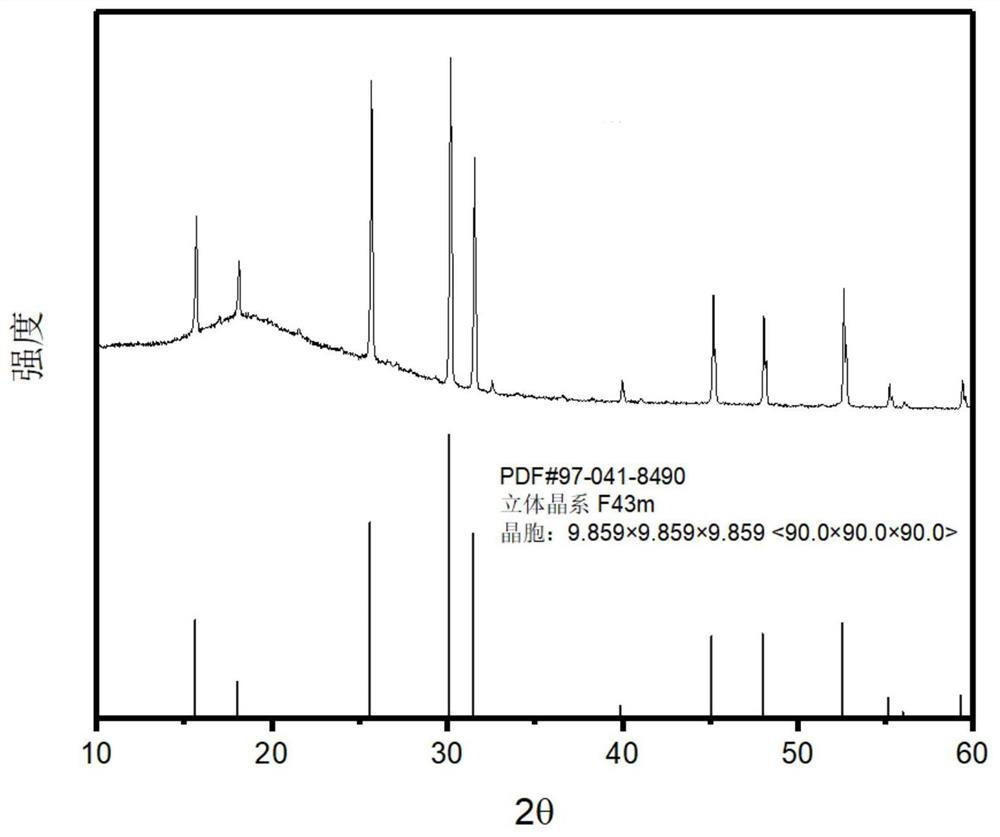

[0024] Weigh 2N pure reagent Li according to the required stoichiometric ratio 2 S, P 2 S 5 and LiCl, put it into a zirconia ball mill jar after mixing, add zirconia balls and ball mill, the ball milling speed is 300rpm, ball mill for 6 hours, then take it out and manually grind it with a mortar for 15min, after sieving through a 300-mesh sieve, you can get a well-mixed Precursor. Place the precursor in the ceramic vibrating tank in the microwave equipment and vibrate and turn over. The schematic diagram of the equipment is shown in Figure 4 As shown, the vibration frequency is 10Hz, the amplitude is 5mm, the temperature is raised to 150°C at a rate of 30°C / min, and the temperature is kept for 10min. After cooling, Li 6 P.S. 5 Cl solid electrolyte powder, please refer to the physical map of solid electrolyte powder figure 1 . from image 3 According to XRD, it can be found that the solid electrolyte powder prepared by this method is argentite-type cubic phase, with goo...

Embodiment 2

[0026] Weigh 2N pure reagent Li according to the required stoichiometric ratio 2 S, P 2 S 5 and LiBr, put it into a zirconia ball mill jar after mixing, add zirconia balls and ball mill, the ball milling speed is 600rpm, ball mill for 6 hours, then take it out and manually grind it with a mortar for 15min, after sieving through a 600-mesh sieve, you can get a well-mixed Precursor. Place the precursor in the ceramic vibrating tank in the microwave equipment and vibrate and flip, the vibration frequency is 20Hz, the amplitude is 5mm, the temperature is raised to 300°C at a rate of 10°C / min, and the temperature is kept for 40min. After cooling, Li 6 P.S. 5 Br solid electrolyte powder, press the obtained powder under a pressure of 200Mpa, hold the pressure for 3min, and obtain a solid electrolyte tablet. The whole process was carried out under an argon protective atmosphere. The lithium electrical conductivity of the solid electrolyte sheet at room temperature is 4×10 -3 S c...

Embodiment 3

[0028] Weigh 2N pure reagent Li according to the required stoichiometric ratio 2 S, P 2 S5, LiCl and SiS 2 , after mixing, put it into a zirconia ball mill jar, add zirconia balls and mill it, the ball milling speed is 800rpm, mill for 8 hours, then take it out and manually grind it with a mortar for 15 minutes, and sieve through a 300-mesh sieve to get a uniformly mixed precursor . Place the precursor in the ceramic vibrating tank of the microwave equipment and vibrate and flip, the vibration frequency is 20Hz, the amplitude is 5mm, the temperature is raised to 300°C at a rate of 15°C / min, and the temperature is kept for 20min. After cooling, Li 5.4 Si 0.2 P.S. 5 Cl solid electrolyte powder, press the obtained powder under a pressure of 200Mpa, hold the pressure for 3min, and obtain a solid electrolyte tablet. The whole process was carried out under an argon protective atmosphere. The lithium electrical conductivity of the solid electrolyte sheet at room temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com