Alkyl silyl ether modified hydroxyl acrylic emulsion and preparation method thereof and application thereof

A technology of hydroxy acrylic acid and alkyl silyl ether, used in coatings, anti-corrosion coatings, etc., can solve the problems of affecting cross-linking curing, affecting the use effect of two-component coatings, etc., and achieve the effect of excellent paint film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

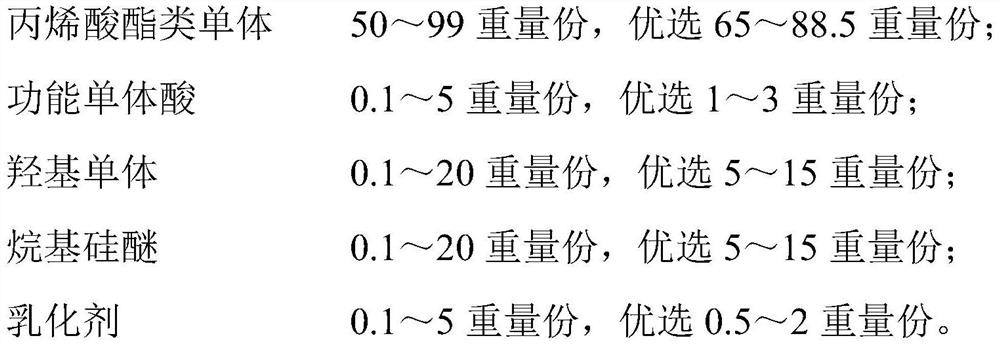

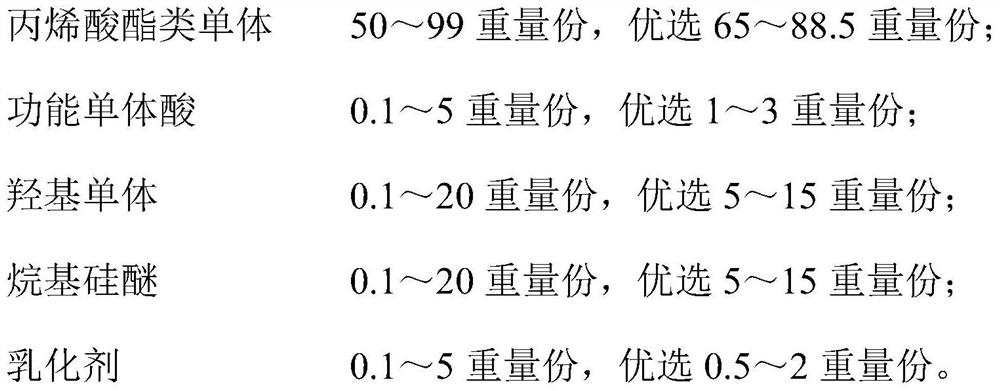

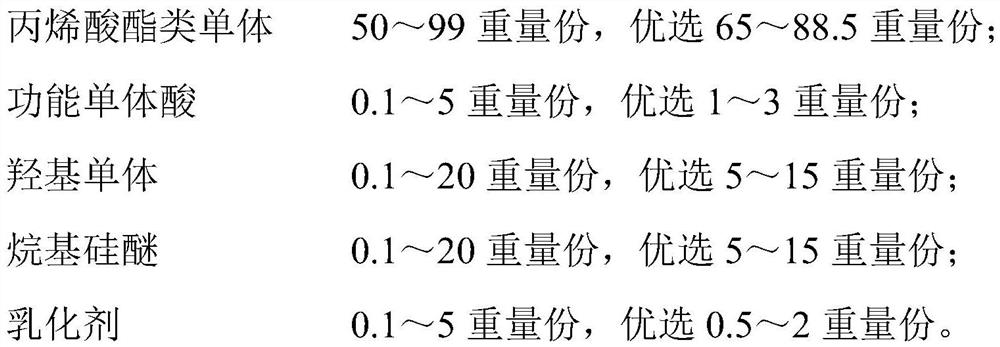

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of alkyl silyl ether modified hydroxyacrylic acid emulsion 1 (hereinafter referred to as emulsion 1 for short)

[0037] Emulsion 1 was prepared as follows:

[0038] (1): Preparation of hydroxyacrylic acid emulsion:

[0039] (1.1) Dissolve 0.9g SDS in 30g water, then add 47g MMA, 30g BA, 10g HEMA and 2gAA in sequence, and stir in the emulsification tank to form a pre-emulsion;

[0040] (1.2) After dissolving 0.1g SDS with 110g deionized water, add it in the reactor, feed nitrogen to exhaust the air in the reactor, and keep the reaction temperature at 85°C; get 4% of the total mass of the pre-emulsion and put it into the reactor as The seed emulsion of nucleus, then add 40% (10%APS, total mass 5.0g) of the gross mass of APS aqueous solution as initiator;

[0041] (1.3) After the polymerization reaction takes place for 30 minutes, add the remaining pre-emulsion and the remaining initiator dropwise for a total of 4 hours while maintaining the react...

Embodiment 2-8

[0044] Example 2-8 Preparation of alkyl silicone ether modified hydroxyacrylic acid emulsion 2-8 (respectively referred to as emulsion 2-8 hereinafter)

[0045] Emulsion 2-8 was prepared using a method similar to that of Example 1, the only difference being that each raw material and its dosage and polymerization reaction temperature are shown in Table 2.

Embodiment 9

[0063] With the emulsion 1 prepared in embodiment 1 as raw material, prepare water-based two-component acrylic anticorrosion coating according to the following method:

[0064] First, add 3.5g of water, 0.3g of 104E, 8.5g of BYK-190, 0.2g of BYK-011 into the dispersion tank, and stir at 300r / min for 10min. Add 37.5g of R706, increase the speed to 800r / min, and disperse evenly at high speed, then add zirconium beads equal to the volume of titanium dioxide, and grind the slurry to a fineness of ≤35μm. Reduce the rotational speed, add 34g of the emulsion 1 prepared in Example 1 under stirring at 300r / min, add DMEA (N,N-dimethylethanolamine) to adjust the pH at 8.0-9.0, then add 2.5g of ethylene glycol butyl ether, 2.5g of Dipropylene glycol butyl ether, 0.1g Tego-4100, 0.5g BYK-825, then dilute 4.8g Aquolin270 with 1.2g propylene glycol diacetate and add to the dispersion tank, add 0.5g BYK-425 according to the viscosity of the paint, replenish water 3.4g and stir well. Filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com