Synthesis method of silver nanowire ink and preparation method of flexible conductive film

A technology of silver nanowires and synthesis method, applied in ink, nanotechnology, metal processing equipment and other directions, can solve problems such as high temperature sintering and curing, and achieve the effect of excellent electrical conductivity and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

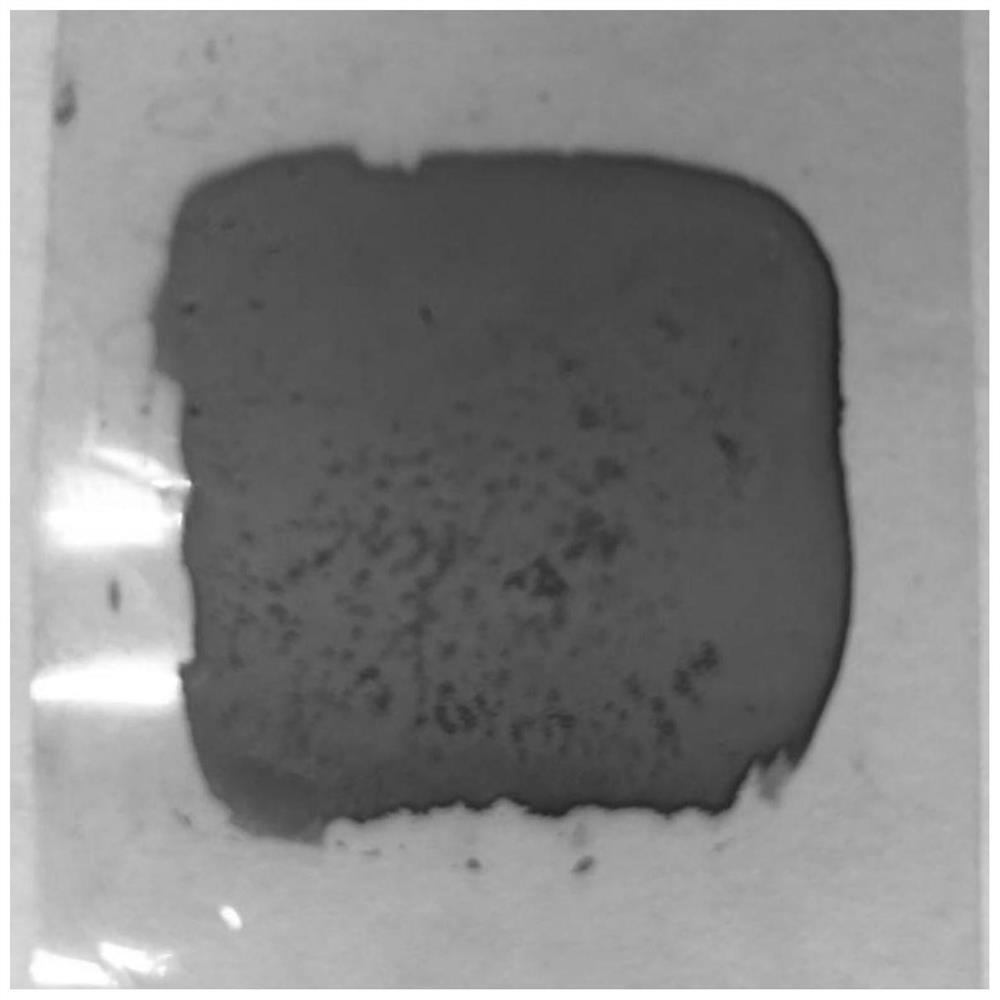

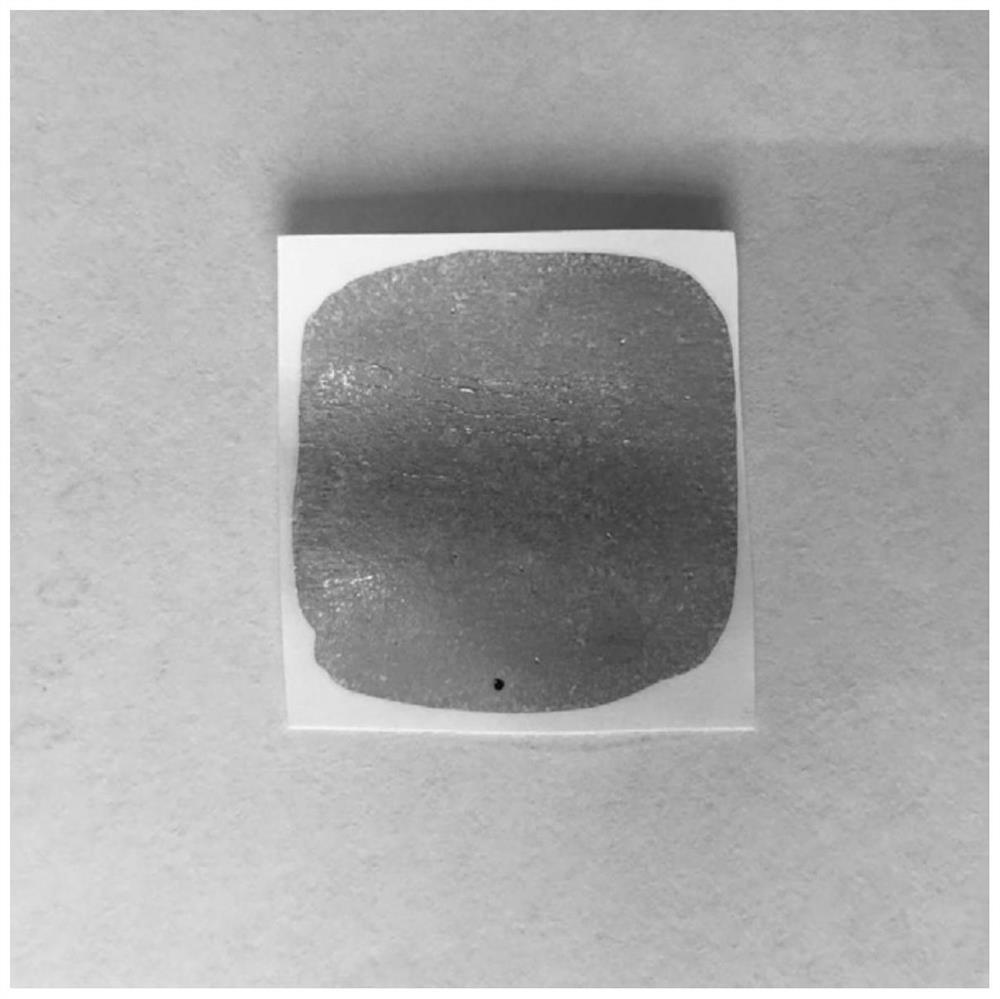

[0035] A kind of preparation method of flexible conductive film of the present invention, specifically implement according to following steps:

[0036] Step (1), the silver nanowire ink prepared by the synthetic method of above-mentioned a kind of silver nanowire ink is evenly coated on the base material, obtains conductive film A after drying at room temperature; The thickness of silver nanowire conductive ink layer in conductive film A 1×10 -7 ~1×10 -6 m, the square resistance is 1×10 -6 Ω·cm~1×10 -4 Ω·cm, where the coating method is printing, such as lithography, inkjet printing, screen printing, etc., or wire bar coating method or Meyer rod coating method, and the substrate is paper, such as coated paper, offset printing paper etc., or plastic films, such as polyester (PET) film, polyethylene (PE) film, etc.;

[0037] In step (2), the conductive film A is dried and cured in a constant temperature drying oven, the curing temperature is 150°C to 300°C, and the curing tim...

Embodiment 1

[0039] Dissolve polycarbonate fiber, silver nitrate, polyvinylpyrrolidone PVP in ethylene glycol solution, and then add mass concentration 8×10 -5 g / mL ferric chloride aqueous solution to form a mixed solution, wherein the mass fraction of polycarbonate fiber in the mixed solution is 0.02%, the mass fraction of silver nitrate is 1.5%, the mass fraction of PVP is 2%, and the mass fraction of ferric chloride aqueous solution The fraction is 2%, and the mass fraction of ethylene glycol is 94.48%. The mixed solution is magnetically stirred at 50°C for 60min. After the color of the solution turns dark reddish brown, the temperature is raised to 140°C, and the temperature is magnetically stirred for 100min. After the reaction is finished, the mother liquor obtained by the reaction is centrifuged and washed with absolute ethanol several times to obtain a precipitate;

[0040]Take 0.22g of the above-mentioned precipitate and disperse it in 1mL of absolute ethanol to make the mass conc...

Embodiment 2

[0042] Dissolve polycarbonate fiber, silver nitrate, and polyvinylpyrrolidone PVP in the ethylene glycol solution, and then add a mass concentration of 1×10 -5 g / mL ferric chloride aqueous solution to form a mixed solution, wherein, in the mixed solution, the polycarbonate fiber mass fraction is 0.06%, the silver nitrate mass fraction is 1%, the PVP mass fraction is 1%, and the ferric chloride aqueous solution The mass fraction is 1%, and the mass fraction of ethylene glycol is 96.94%. The mixed solution is magnetically stirred at 60°C for 50 minutes. After the color of the solution turns dark reddish brown, the temperature is raised to 160°C, and the temperature is magnetically stirred for 90 minutes. After the reaction is finished, the mother liquor obtained by the reaction is centrifuged and washed with absolute ethanol several times to obtain a precipitate;

[0043] Take 0.44g of the above-mentioned precipitate and disperse it in 3mL of absolute ethanol to make the mass co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com