Method for producing medium-chain alcohol through fermentation of exogenous medium enhanced anaerobic microorganisms

An anaerobic microorganism and medium strengthening technology is applied in the field of exogenous medium strengthening anaerobic microorganism fermentation production of medium-chain alcohol, which can solve the problems of restricting industrialization development, low gas-liquid mass transfer efficiency, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] A kind of domestication method of anaerobic medium chain alcohol microorganism, concrete steps are as follows:

[0138] 1) Configure the medium, add 100mM acetic acid in the medium;

[0139] 2) Add culture medium and inoculate anaerobic microorganisms;

[0140] 3) Regulating temperature and pH, feeding synthesis gas, and reacting in a shaker reactor;

[0141] 4) The headspace CO pressure is adjusted to 0.3atm and maintained for 15-60 days;

[0142] 5) When the 24-hour headspace CO consumption in the reactor is >50%, adjust the headspace CO pressure to 0.7atm for 10-30 days;

[0143] 6) When the 24-hour headspace CO consumption in the reactor is >50%, adjust the headspace CO pressure to 1 atmCO for 10-30 days;

[0144] 7) When the 24-hour headspace CO consumption in the reactor is >50%, the acclimatization is completed, and anaerobic medium-chain alcohol-producing microorganisms are obtained.

[0145] In this embodiment, the temperature is controlled at 35° C., the i...

Embodiment 2

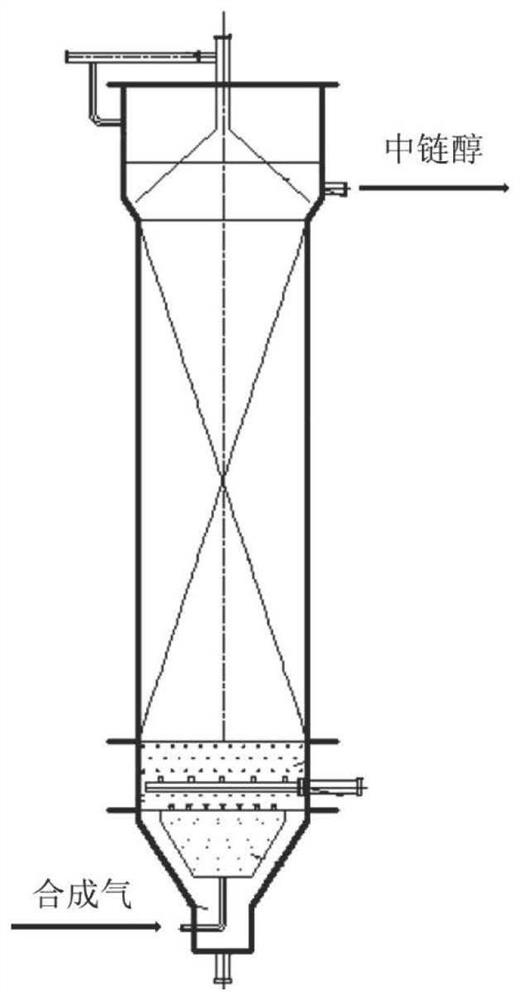

[0147] A method for producing medium-chain alcohols in a single-phase reactor by mixing an exogenous medium with anaerobic alcohol-producing microorganisms, the specific steps are as follows:

[0148] 1) Weigh chloroplatinic acid, dissolve it in ethylene glycol, and stir to make it dissolve evenly;

[0149] 2) Weigh Fe 2 o 3 powder, drop the solution obtained in step 1) into Fe 2 o 3 in, stir to mix thoroughly;

[0150] 3) Transfer the material prepared in step 2) to a drying oven, and dry it in an air atmosphere at 150°C for 12 hours;

[0151] 4) After drying the catalyst in step 3) at 400°C, use H 2 The / CO volume ratio is 1:1 and the synthesis gas is reduced for 12 hours to obtain an inorganic solid catalyst (external medium iron-supported platinum catalyst);

[0152] 5) Put the activated sludge sterilized by high-pressure steam at 120°C for 60 minutes into the anaerobic fermentation reactor, and add the necessary medium; keep the temperature at 35°C, and cultivate an...

Embodiment 3

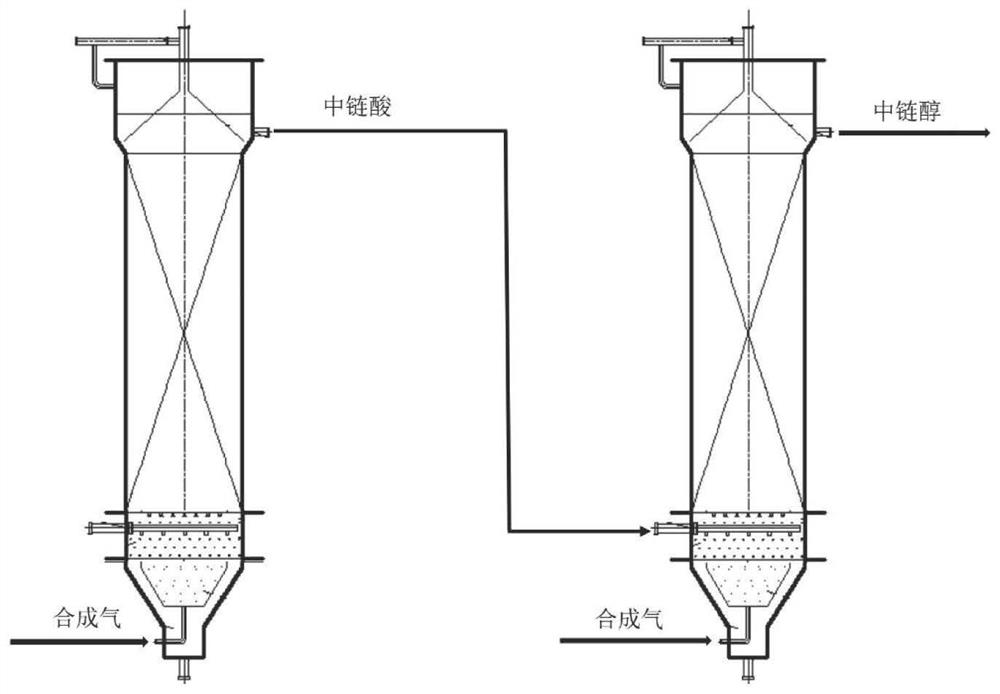

[0167] A method for producing medium-chain alcohols in a two-phase reactor by mixing an exogenous medium with anaerobic alcohol-producing microorganisms, the specific steps are as follows:

[0168] 1) Weigh chloroplatinic acid, dissolve it in ethylene glycol, and stir to make it dissolve evenly;

[0169] 2) Weigh Fe 2 o 3 powder, drop the solution obtained in step 1) into Fe 2 o 3 in, stir to mix thoroughly;

[0170] 3) Transfer the material prepared in step 2) to a drying oven, and dry it in an air atmosphere at 150°C for 12 hours;

[0171] 4) After drying the catalyst in step 3) at 400°C, use H 2 The / CO volume ratio is 1:1 and the synthesis gas is reduced for 12 hours to obtain an inorganic solid catalyst (external medium iron-supported platinum catalyst);

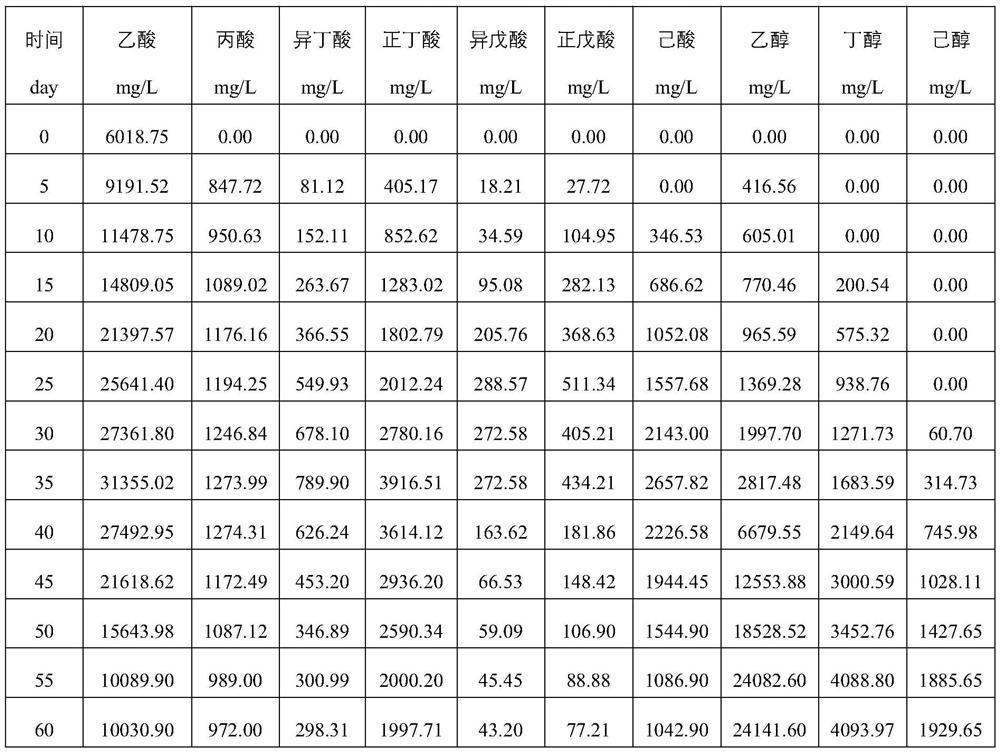

[0172] 5) Put the activated sludge sterilized by high-pressure steam at 120°C for 60 minutes into the anaerobic fermentation reactor, and add the necessary medium; keep the temperature at 35°C, and cultivate and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com