Environment-friendly degradable waterproof coating packaging paper and preparation method thereof

A technology for waterproof coating and wrapping paper, applied in the directions of wrapping paper, packaging, biological packaging, etc., can solve the problems of complex production process, insufficient heat-sealing strength, poor heat-sealing property, etc., and achieve simple production process, improved comprehensive performance, mechanical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

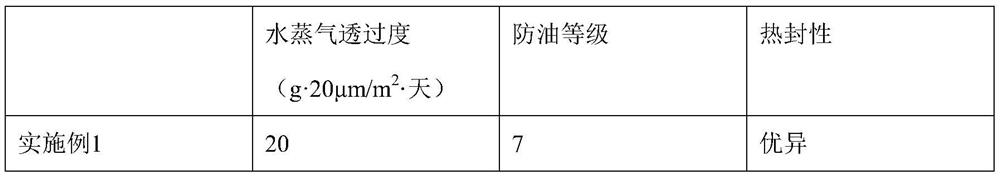

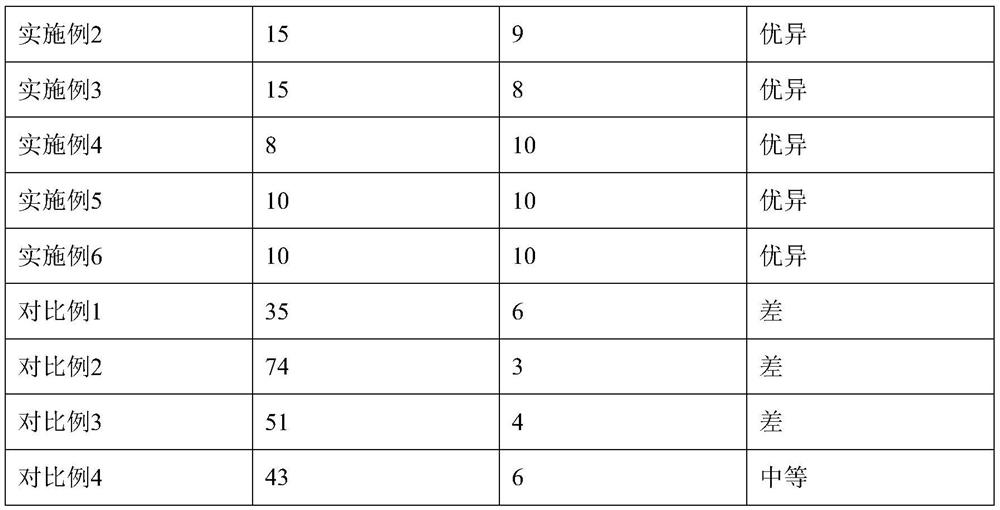

Examples

Embodiment 1

[0031] An environmentally friendly degradable waterproof coated wrapping paper, comprising a paper substrate, an inner layer, an intermediate layer and an outer layer are sequentially arranged on one side of the paper substrate; the inner layer includes 70% by weight of polyvinyl alcohol acid copolymer and 30% by weight of thermoplastic starch, the polyvinyl alcohol acid copolymer contains more than 60% by weight of glycolic acid repeating units, and the weight average molecular weight of the polyvinyl alcohol acid copolymer is 100,000;

[0032] The middle layer includes 40% by weight of polyvinyl alcohol, 30% by weight of thermoplastic starch, 20% by weight of plasticizer, 5% by weight of compatibilizer and 5% by weight of stabilizer, and the degree of alcoholysis of the polyvinyl alcohol is between More than 70%;

[0033] The outer layer comprises 40% by weight of degradable polyester copolymer, 20% by weight of thermoplastic starch, 20% by weight of polydioxanone, 10% by weig...

Embodiment 2

[0040] An environmentally friendly and degradable waterproof coated wrapping paper, comprising a paper substrate, an inner layer, an intermediate layer and an outer layer are sequentially arranged on one side of the paper substrate; the inner layer includes 95% by weight of polyvinyl alcohol acid copolymer and 5% by weight of thermoplastic starch, the polyvinyl alcohol acid copolymer contains more than 70% by weight of glycolic acid repeating units, and the weight average molecular weight of the polyvinyl alcohol acid copolymer is 300,000;

[0041] The middle layer includes 60% by weight of polyvinyl alcohol, 20% by weight of thermoplastic starch, 5% by weight of plasticizer, 5% by weight of compatibilizer and 2% by weight of stabilizer, and the degree of alcoholysis of the polyvinyl alcohol is at More than 70%;

[0042] The outer layer comprises 60% by weight of degradable polyester copolymer, 10% by weight of thermoplastic starch, 10% by weight of polydioxanone, 10% by weigh...

Embodiment 3

[0049] An environmentally friendly degradable waterproof coated wrapping paper, comprising a paper substrate, an inner layer, an intermediate layer and an outer layer are sequentially arranged on one side of the paper substrate; the inner layer includes 80% by weight of polyvinyl alcohol acid copolymer and 20% by weight of thermoplastic starch, the polyvinyl alcohol acid copolymer contains more than 70% by weight of glycolic acid repeating units, and the weight average molecular weight of the polyvinyl alcohol acid copolymer is 500,000;

[0050] The middle layer includes 50% by weight of polyvinyl alcohol, 25% by weight of thermoplastic starch, 15% by weight of plasticizer, 5% by weight of compatibilizer and 2% by weight of antioxidant, the degree of alcoholysis of the polyvinyl alcohol Above 80%;

[0051] The outer layer comprises 50% by weight of degradable polyester copolymer, 15% by weight of thermoplastic starch, 15% by weight of polydioxanone, 7% by weight of plasticizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com