Method for rapidly preparing colloidal photonic crystal array chip by utilizing laser direct writing

A colloidal photonic crystal and chip technology, which is used in crystal growth, optomechanical equipment, microlithography exposure equipment, etc., to achieve the effect of wide application range, simple operation, and avoidance of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for rapidly preparing a colloidal photonic crystal array chip by using laser direct writing on the surface of a glass substrate, the specific steps are as follows:

[0026] (1) Prepare a square glass sheet with a side length of 2.5 cm as the base material;

[0027] (2) Hydrophilic treatment of the substrate, followed by N 2 blow dry;

[0028] (3) Prepare a polystyrene photonic crystal layer on the substrate;

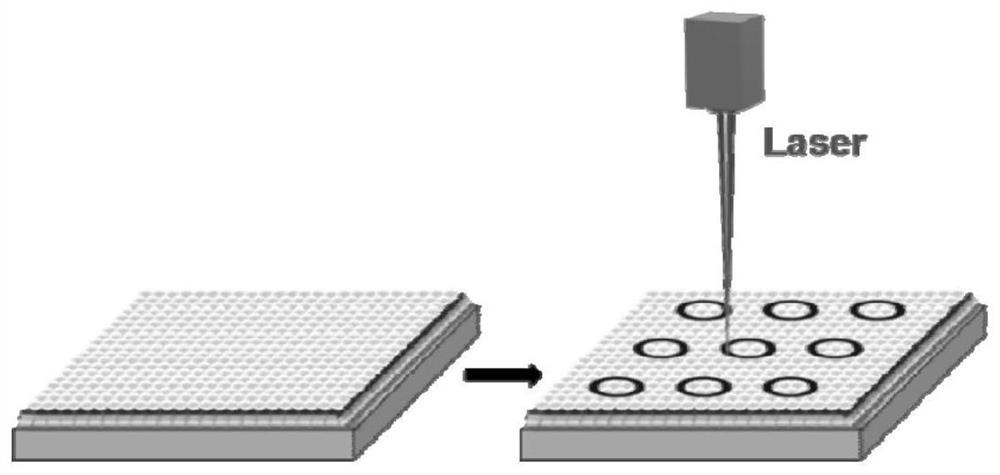

[0029] (4) Use the software to design the circular array pattern to be etched, and import the file into the carbon dioxide laser device.

[0030] (5) Place the substrate with the photonic crystal layer on the operating table, set the direct writing speed of the carbon dioxide laser to 600mm / s, and the laser power to 12W.

[0031] (6) Start the laser device.

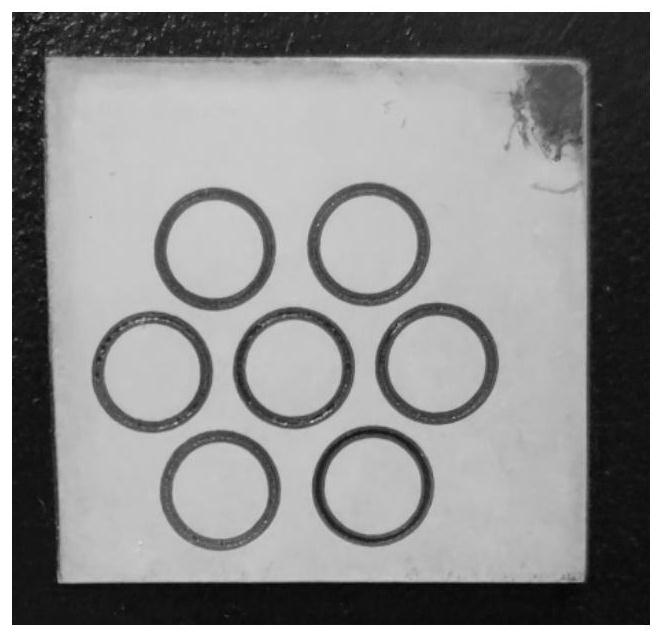

[0032] (7) After the etching is finished, turn off the laser. The colloidal photonic crystal chip ( figure 2 ).

[0033] The method of the invention is easy to prepare, does not need complex ...

Embodiment 2

[0035] A method for rapidly preparing a colloidal photonic crystal array chip on the surface of a PMMA substrate using laser direct writing, the specific steps are as follows:

[0036] (1) Prepare a square PMMA sheet with a side length of 2.5 cm as the base material;

[0037] (2) The surface of the substrate is treated with hydrophilicity, and then N 2 blow dry;

[0038] (3) Prepare a polystyrene photonic crystal layer on the substrate;

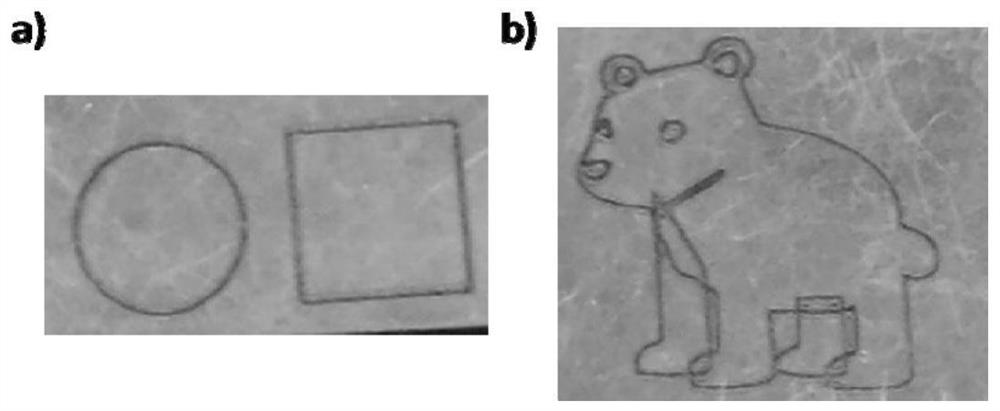

[0039] (4) Use the software to design the square array pattern to be etched, and import the file into the carbon dioxide laser equipment.

[0040] (5) Place the substrate with the photonic crystal layer on the operating table, set the direct writing speed of the carbon dioxide laser to 600mm / s, and the laser power to 12W.

[0041] (6) Start the laser device.

[0042] (7) After the etching is finished, turn off the laser. Colloidal photonic crystal chips ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com