A preparation method and application of thin film transistor fine mask

A technology of thin film transistors and mask plates, which is applied in the field of preparation of fine mask plates for thin film transistors, can solve the problems of high manufacturing process costs, and achieve the effects of less process flow, low cost, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

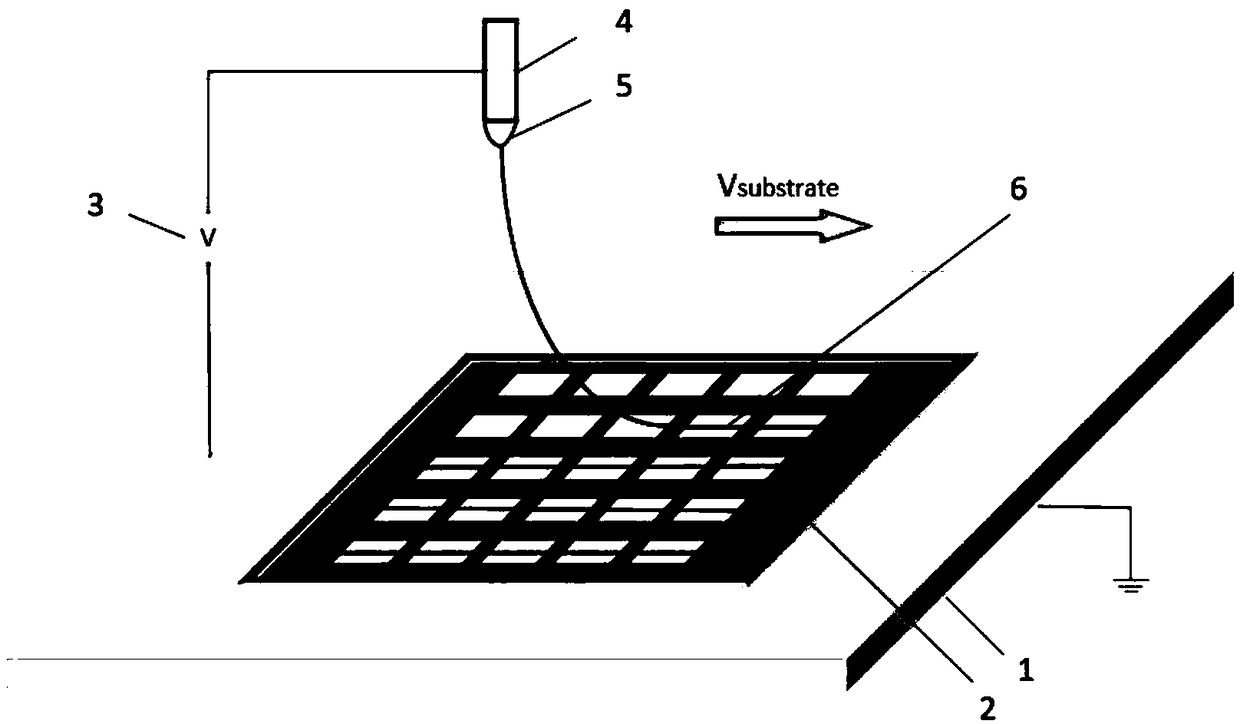

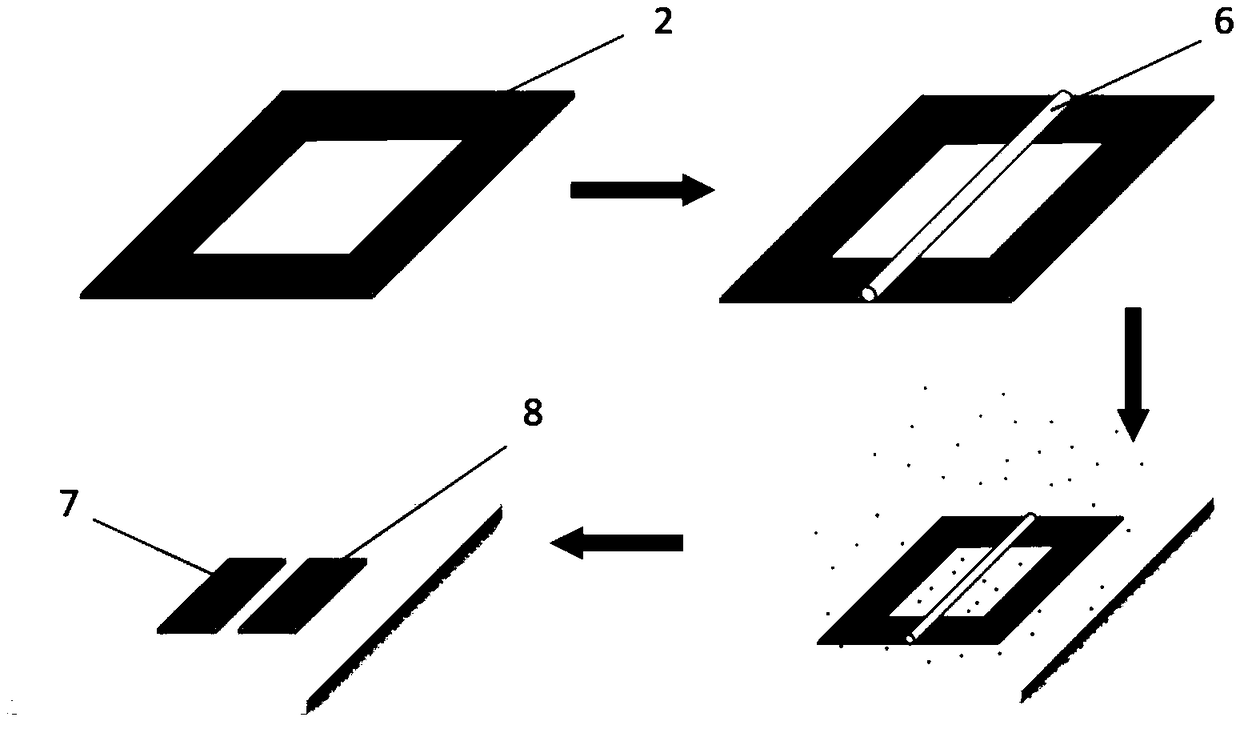

[0036] figure 1Schematic diagram for the preparation of mask plates by electrospinning method. A method for preparing a thin film transistor fine mask according to the present invention specifically comprises the following steps:

[0037] S1. Prepare a thin metal plate, and etch a plurality of hollow patterns on the thin metal plate, and the hollow patterns are distributed in an array, thereby preparing a hollow metal thin plate;

[0038] S2. Prepare an electrospinning solution for spinning submicron fibers;

[0039] S3. Use the electrospinning solution prepared in step S2 to spin submicron fibers on the thin metal plate prepared in step S1. The single fiber spun spans the hollow part of the thin metal plate, and the hollow part of the thin metal plate is spun. Evenly divided into two adjacent areas;

[0040] S4. After the fibers are solidified, a tube fine mask for preparing thin film crystals composed of metal sheets and fibers is obtained.

[0041] In a preferred embodi...

Embodiment 1

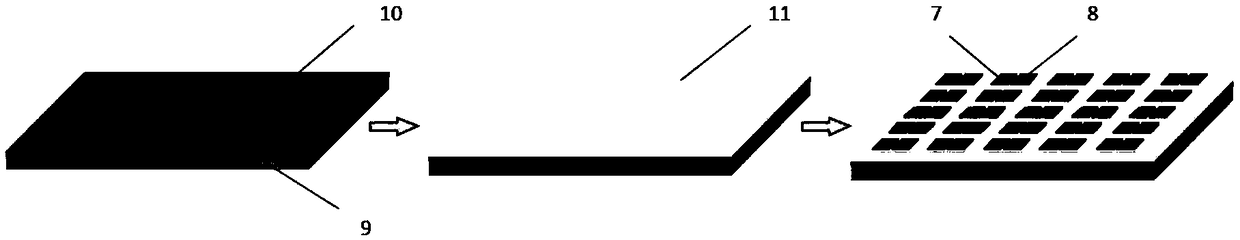

[0056] Utilize process method described in the present invention to manufacture thin film transistor process on silicon substrate as follows:

[0057] (1) Preparation of a semiconductor layer. Add 10mg of P3HT powder to 990mg of chlorobenzene, heat at 70°C, and dissolve with 100W ultrasonic for 1-2h. After the solution has no obvious particles, heat at 60-70°C and magnetically stir for 2-3h to form a uniform semiconductor solution. After standing for 30 minutes, filter with a 0.02um sieve to obtain the prepared organic semiconductor solution. Outsourced silicon oxide wafer, in which N++Si is the gate, with a thickness of about 200 μm, such as image 3 As shown in middle 9, SiO2 is an insulating layer with a thickness of about 100nm, such as image 3 Shown in 10. The semiconductor solution is spin-coated on the surface of the SiO2 insulating layer, the rotation speed is 1500r / min, and the time is 75s. The thickness of the obtained P3HT film is generally controlled between 50...

Embodiment 2

[0061] The process of manufacturing a flexible thin film transistor using the process method described in the present invention is as follows:

[0062] (1) Prepare the metal grid. Cut the PI film with a thickness of 30-50 μm into a square of 10 cm × 10 cm, ultrasonically clean it with acetone, absolute ethanol, and deionized water for 10 min, and finally dry it with nitrogen. Use the method of thermal evaporation coating to plate gold on the cleaned PI film with a thickness of 100-300nm, such as Figure 4 Shown in 13.

[0063] (2) Prepare an insulating layer. Dissolve an appropriate amount of polymethyl methacrylate (PMMA) in a chlorobenzene solution to form a solution of 5-10 mg / ml, and spin-coat it on the surface of the gate at a speed of 1000 r / min for 60 seconds, and control the thickness at 100~ 300nm, dry the film at 100°C-150°C after spin coating, such as Figure 4 Shown in 14.

[0064] (3) Preparation of an organic semiconductor layer. Add 10mg of P3HT powder to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com