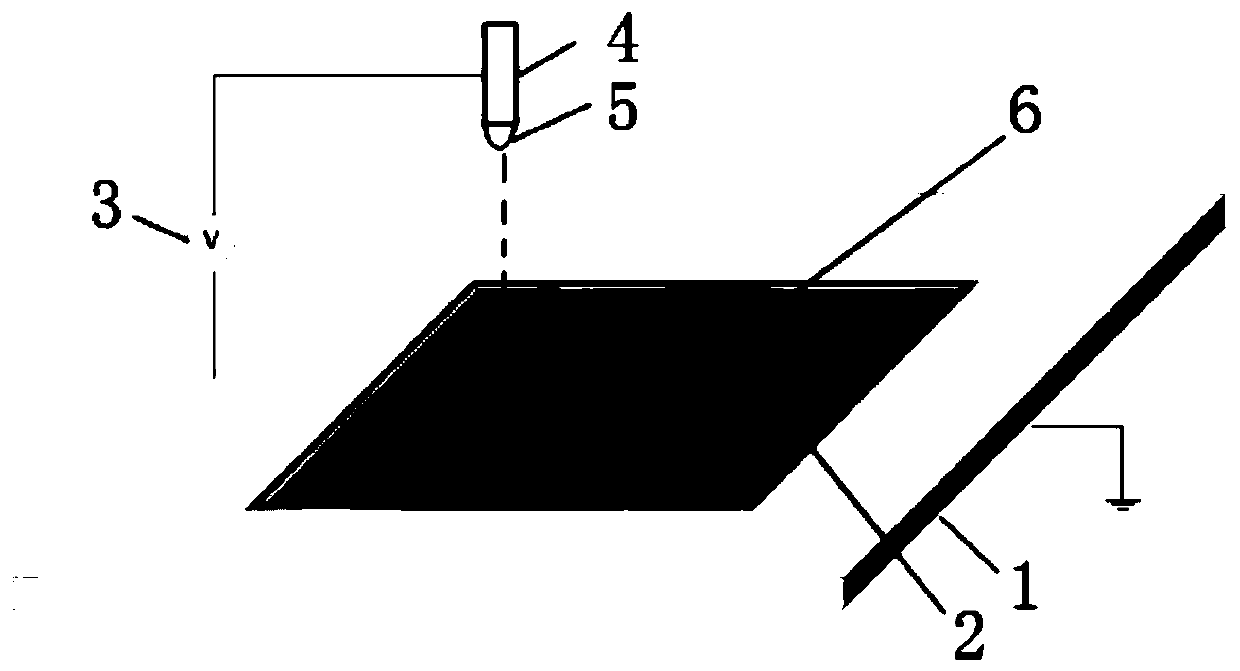

Top-emitting OLED device with cathode single-sided grating and manufacturing method thereof

A top-emitting, grating technology, applied in the field of top-emitting OLED devices and its preparation, can solve the problems of preparing gratings, and achieve the effects of fewer processes, improved luminous efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

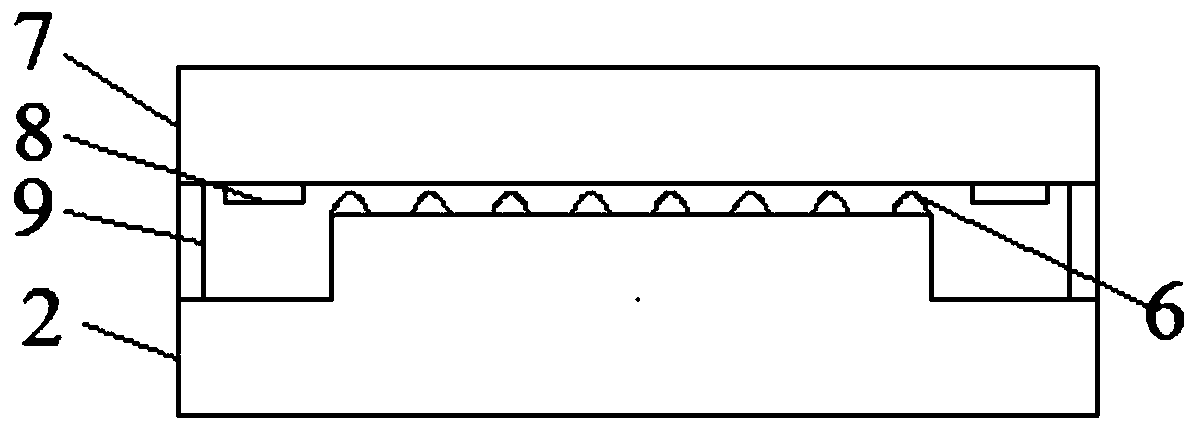

Method used

Image

Examples

Embodiment 1

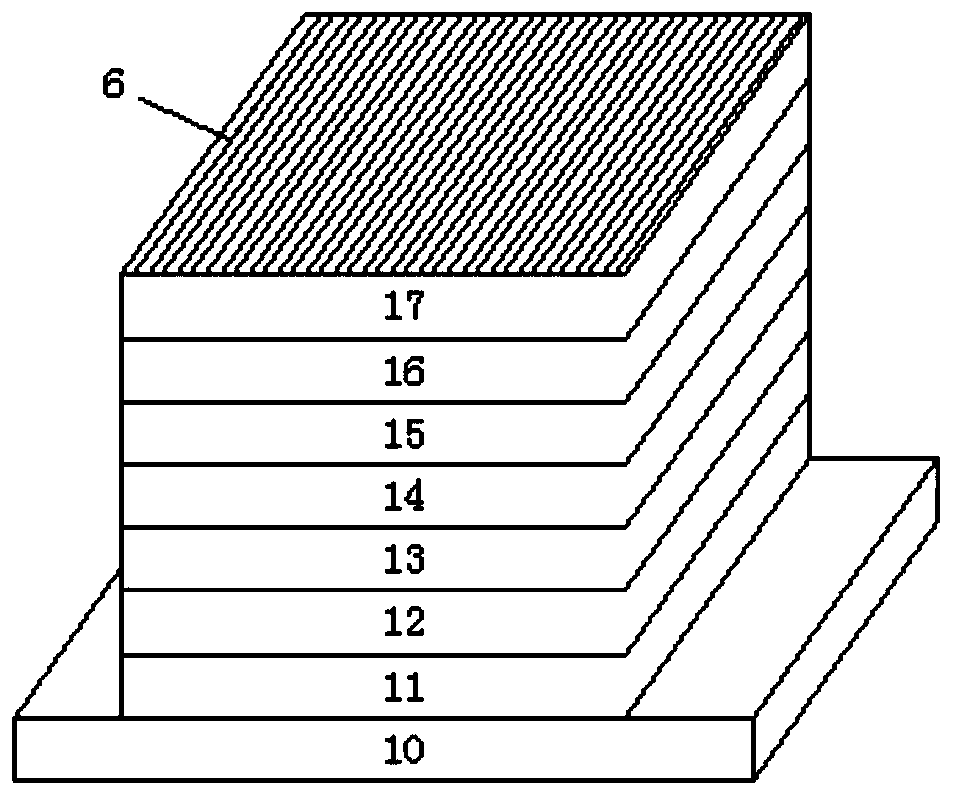

[0035] 1) Prepare the substrate 10, which is an ITO-coated glass substrate. Sonicate with acetone, absolute ethanol, and deionized water for 10 minutes, then blow dry with nitrogen, and finally heat in a vacuum oven at 80° C. for 30 minutes.

[0036] 2) Preparation of a top-emitting OLED device 2 suitable for monochromatic green light. The existing common green light OLED structure is adopted. at 3×10 -4 100nmAl is vapor-deposited under Pa pressure environment to form the metal anode 11, and then successively vapor-deposits 10nm molybdenum trioxide (MoO 3) as hole injection layer 12, 52 nm of N,N'-diphenyl-N,N'-(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB) as Hole transport layer 13, 20nm 8-hydroxyquinoline aluminum (Alq 3 ) as the OLED light-emitting layer 14 suitable for green light, 15nm phenanthroline (BPhen) doped with lithium (Li) (BPhen: Li) as the electron injection layer 16 to reduce the electron injection barrier and improve conductivity. 10nm of BPhen is used as...

Embodiment 2

[0041] 1) Prepare the substrate 10, which is an ITO glass substrate. Sonicate with acetone, absolute ethanol, and deionized water for 20 minutes respectively, then blow dry with nitrogen, and finally heat in a vacuum oven at 90° C. for 20 minutes.

[0042] 2) Preparation of a top-emitting OLED device 2 suitable for white light. The existing common white light OLED structure is adopted. at 3×10 - 4 The metal anode 11 is formed by evaporating 100nm Al under Pa pressure environment, and then depositing a hole injection layer 12 with a thickness of 5nm in sequence. Triphenylamine) is formed, 40nm thick hole transport layer 13, hole transport layer 13 adopts TAPC (two-[4-(N,N-xylyl-amino)-phenyl] cyclohexane) to form, redeposition OLED light-emitting layer 14, OLED light-emitting layer 14 includes a 19nm-thick blue light unit and a 1nm-thick yellow light unit, which can emit white light. Pyridyl)phenyl-(2-carboxypyridyl)iridium(III)) is doped with host material mCP(N,N′-dicarba...

Embodiment 3

[0047] 1) Prepare the substrate 10, the substrate 10 is an ITO glass substrate, ultrasonically use acetone, absolute ethanol, and deionized water for 30 minutes, then blow dry with nitrogen, and finally heat in a vacuum oven at 100°C for 10 minutes .

[0048] 2) Preparation of a top-emitting OLED device 2 suitable for white light. The existing common white light OLED structure is adopted. at 3×10 - 4 The metal anode 11 is formed by evaporating 100nm Al under Pa pressure environment, and then depositing a hole injection layer 12 with a thickness of 5nm in sequence. Triphenylamine) is formed, 40nm thick hole transport layer 13, hole transport layer 13 adopts TAPC (two-[4-(N,N-xylyl-amino)-phenyl] cyclohexane) to form, redeposition OLED light-emitting layer 14, OLED light-emitting layer 14 includes a 19nm-thick blue light unit and a 1nm-thick yellow light unit, which can emit white light. Pyridyl)phenyl-(2-carboxypyridyl)iridium(III)) is doped with host material mCP(N,N′-dic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com