Method for preparing xylose from dissolving pulp precooking waste liquid

A technology of precooking and dissolving pulp, which is applied in the fields of xylose production, sugar production, sugar derivative preparation, etc., can solve the problems of reducing the utilization rate of dissolving pulp precooking waste liquid, polluting the environment, etc., and achieve high-value utilization , reduce waste water discharge, increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, xylose is prepared by precooking waste liquid of dissolving pulp. Using dissolving pulp precooking waste liquid as raw material, the solid content of dissolving pulp precooking waste liquid is 5%, the density is 1.01g / mL, and the pH value is 3.5; lignin accounts for the solid content of dissolving pulp precooking waste liquid The mass percentage of hemicellulose in the solid content of the dissolving pulp precooking waste liquid is 35% in the solid content.

[0048] The preparation method of xylose specifically comprises the following steps:

[0049](1) Mix the above-mentioned dissolving pulp pre-cooking waste liquid with lye, adjust the pH of the system to 9, and at 60°C, use a 325-mesh stainless steel mesh filter to filter the dissolving pulp pre-cooking waste liquid to remove the dissolving pulp Sawdust and particulate impurities in the precooking waste liquid, the filter membrane pore size is 5 μm, and the collected filtrate is material A; the s...

Embodiment 2

[0054] In this embodiment, xylose is prepared by precooking waste liquid of dissolving pulp. Using dissolving pulp precooking waste liquid as raw material, the solid content of dissolving pulp precooking waste liquid is 6%, the density is 1.02g / mL, and the pH value is 4.5; lignin accounts for the solid content of dissolving pulp precooking waste liquid The mass percentage of hemicellulose in the solids of dissolving pulp precooking waste liquid is 24%; the mass percentage of hemicellulose in the solids is 40%.

[0055] The preparation method of xylose specifically comprises the following steps:

[0056] (1) Mix the above-mentioned dissolving pulp pre-cooking waste liquid with lye, adjust the pH of the system to 10, and at 65°C, use a 325-mesh stainless steel mesh filter to filter the dissolving pulp pre-cooking waste liquid to remove the dissolving pulp Sawdust and particulate impurities in the precooking waste liquid, the filter membrane pore size is 10 μm, and the collected...

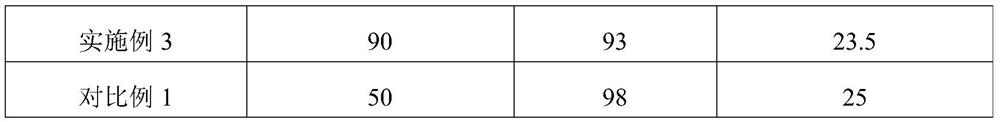

Embodiment 3

[0061] In this embodiment, xylose is prepared by precooking waste liquid of dissolving pulp. Using dissolving pulp precooking waste liquid as raw material, the solid content of dissolving pulp precooking waste liquid is 7%, the density is 1.04g / mL, and the pH value is 5.5; The mass percent of hemicellulose in the solids of dissolving pulp precooking waste liquid is 28%; the mass percent of hemicellulose in the solids is 45%.

[0062] The preparation method of xylose specifically comprises the following steps:

[0063] (1) Mix the above-mentioned dissolving pulp pre-cooking waste liquid with lye, adjust the pH of the system to 11, and use a 325-mesh stainless steel mesh filter to filter the dissolving pulp pre-cooking waste liquid at 70°C to remove the dissolving pulp Sawdust and particulate impurities in the precooking waste liquid, the filter membrane pore size is 20 μm, and the collected filtrate is material A; the solid content of material A is 7%;

[0064] (2) Material A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com