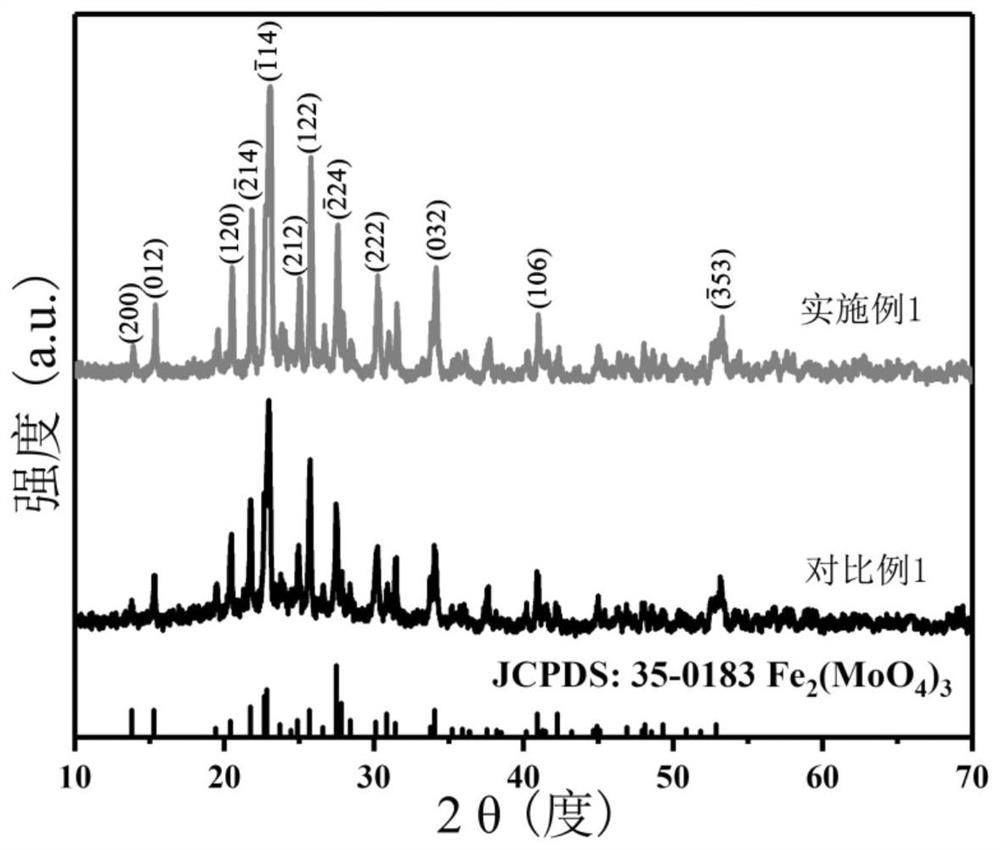

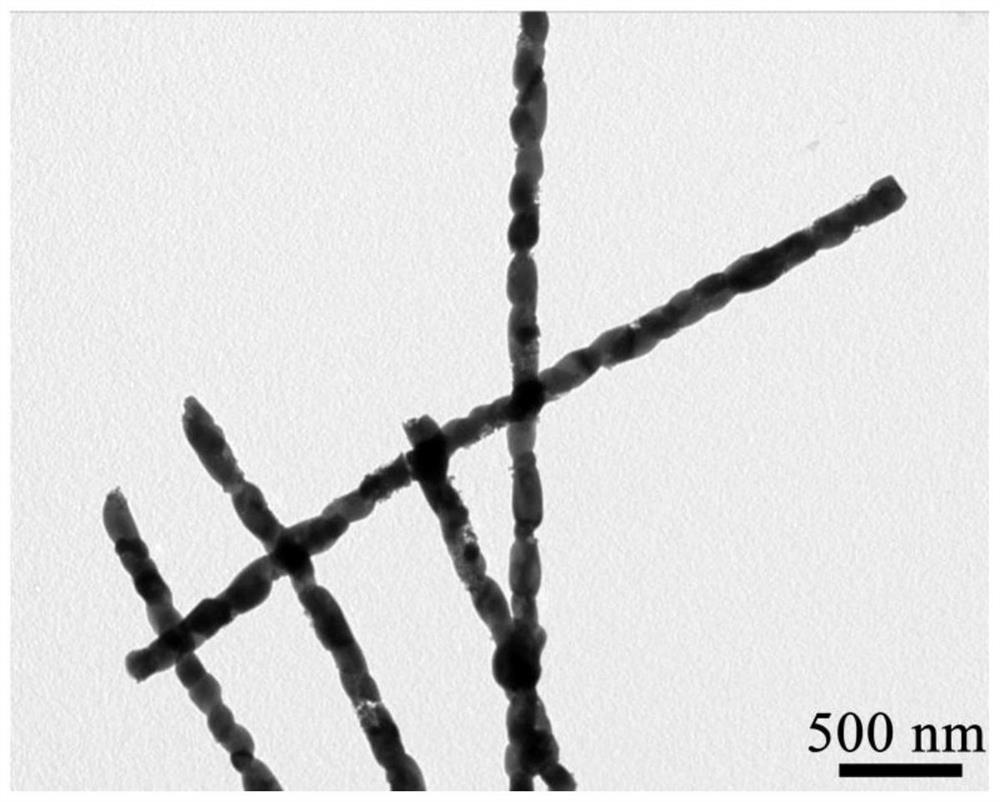

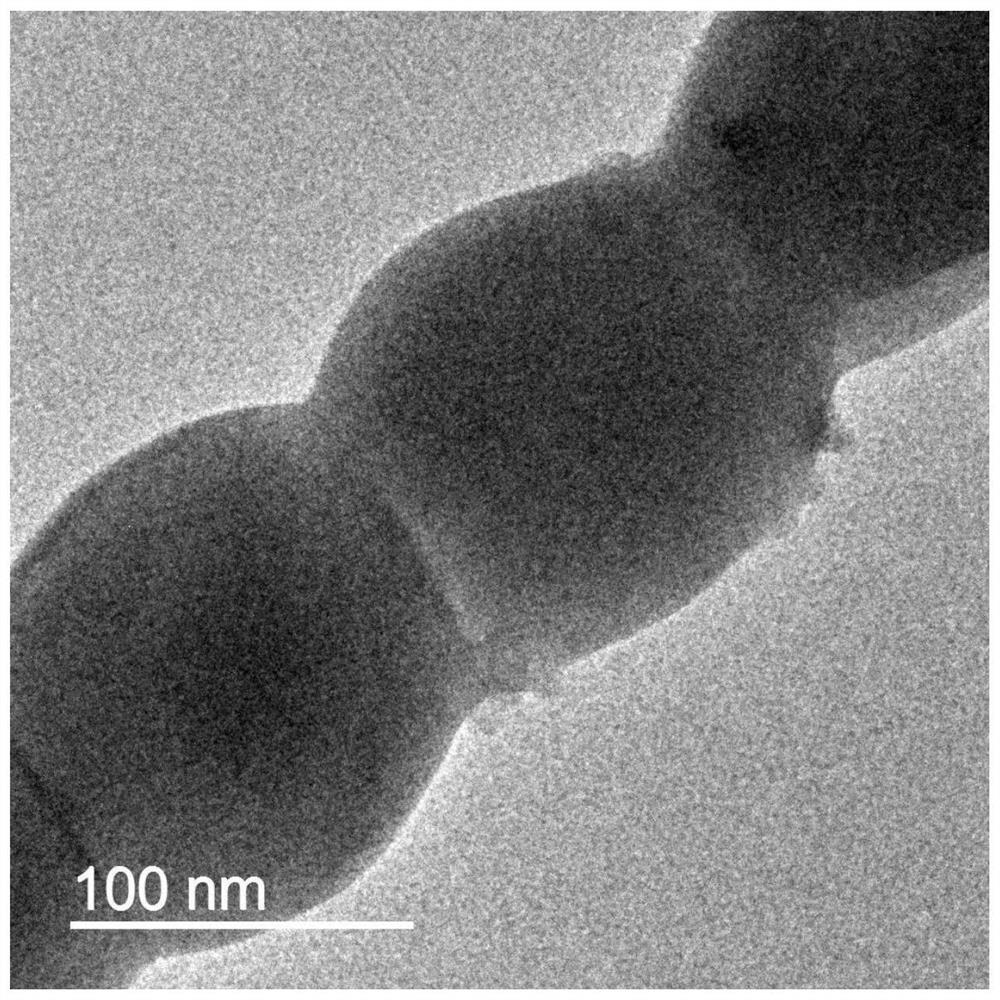

Beaded iron molybdate nanofiber photocatalyst as well as preparation method and application

A technology of nanofibers and iron molybdate, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Small size, low catalytic activity, etc., to achieve strong adsorption capacity, improve photocatalytic performance and photoelectric conversion efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of beaded iron molybdate nanofibers, comprising the following steps:

[0052] (1) Add 1g of citric acid to a mixed solvent consisting of 4mL of absolute ethanol and 6mL of water, seal it (avoid the volatilization of water, ethanol and other solvents to affect the results), and stir until it is completely dissolved; add 0.15mmol of ammonium molybdate and 2mmol of nine Iron nitrate in water, stirred for 30 minutes; then added 1.5mL of hydrochloric acid solution with a mass concentration of 37wt%, and stirred until clear to obtain an iron molybdate precursor solution;

[0053] (2) Add 6 mL of the ferric molybdate precursor solution prepared in step (1) to a mixed solvent consisting of 10 mL of absolute ethanol and 3 mL of water, stir well, add 1.5 g of polyvinylpyrrolidone (PVP), and stir until dissolved complete, add 1.5mL of hydrochloric acid solution with a mass concentration of 37wt%, and stir evenly to obtain the iron molybdate precursor sol;

[...

Embodiment 2

[0061] A preparation method of beaded iron molybdate nanofibers, comprising the following steps:

[0062] (1) Add 1g of citric acid to a mixed solvent consisting of 4mL of absolute ethanol and 6mL of water, seal it (avoid the volatilization of water, ethanol and other solvents to affect the results), and stir until it is completely dissolved; add 0.15mmol of ammonium molybdate and 2mmol of nine Ferric nitrate in water, stirred for 30 minutes; then 2 mL of hydrochloric acid solution with a mass concentration of 37 wt% was added, and stirred until clear to obtain an iron molybdate precursor solution;

[0063] (2) Add 6 mL of the ferric molybdate precursor solution prepared in step (1) to a mixed solvent consisting of 10 mL of absolute ethanol and 3 mL of water, stir well, add 1.5 g of polyvinylpyrrolidone (PVP), and stir until dissolved complete, add 2mL of hydrochloric acid solution with a mass concentration of 37wt%, and stir evenly to obtain the iron molybdate precursor sol; ...

Embodiment 3

[0067] A preparation method of beaded iron molybdate nanofibers, the steps are as follows:

[0068] (1) Add 1g of citric acid to a mixed solvent consisting of 4mL of absolute ethanol and 6mL of water, seal it (avoid the volatilization of water, ethanol and other solvents to affect the results), and stir until it is completely dissolved; add 0.15mmol of ammonium molybdate and 2mmol of nine Iron nitrate in water, stirred for 30 minutes; then 2.5 mL of hydrochloric acid solution with a mass concentration of 37 wt% was added, and stirred until clear to obtain an iron molybdate precursor solution;

[0069] (2) Add 6 mL of the ferric molybdate precursor solution prepared in step (1) to a mixed solvent consisting of 10 mL of absolute ethanol and 3 mL of water, stir well, add 1.5 g of polyvinylpyrrolidone (PVP), and stir until dissolved complete, add 2.5mL of hydrochloric acid solution with a mass concentration of 37wt%, and stir evenly to obtain the iron molybdate precursor sol;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com